Shuttle vehicle power supply device

A technology of power supply device and shuttle car, which is applied in the field of shuttle cars, can solve the problems of overlapping charging lines, etc., and achieve the effect of avoiding overlapping and high travel accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

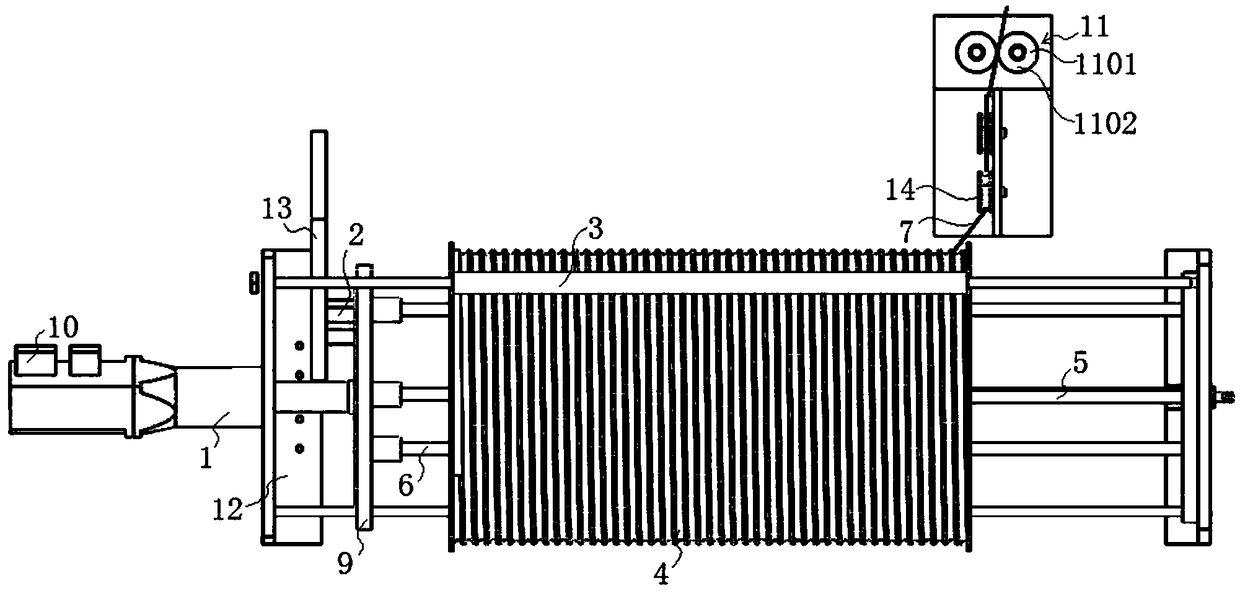

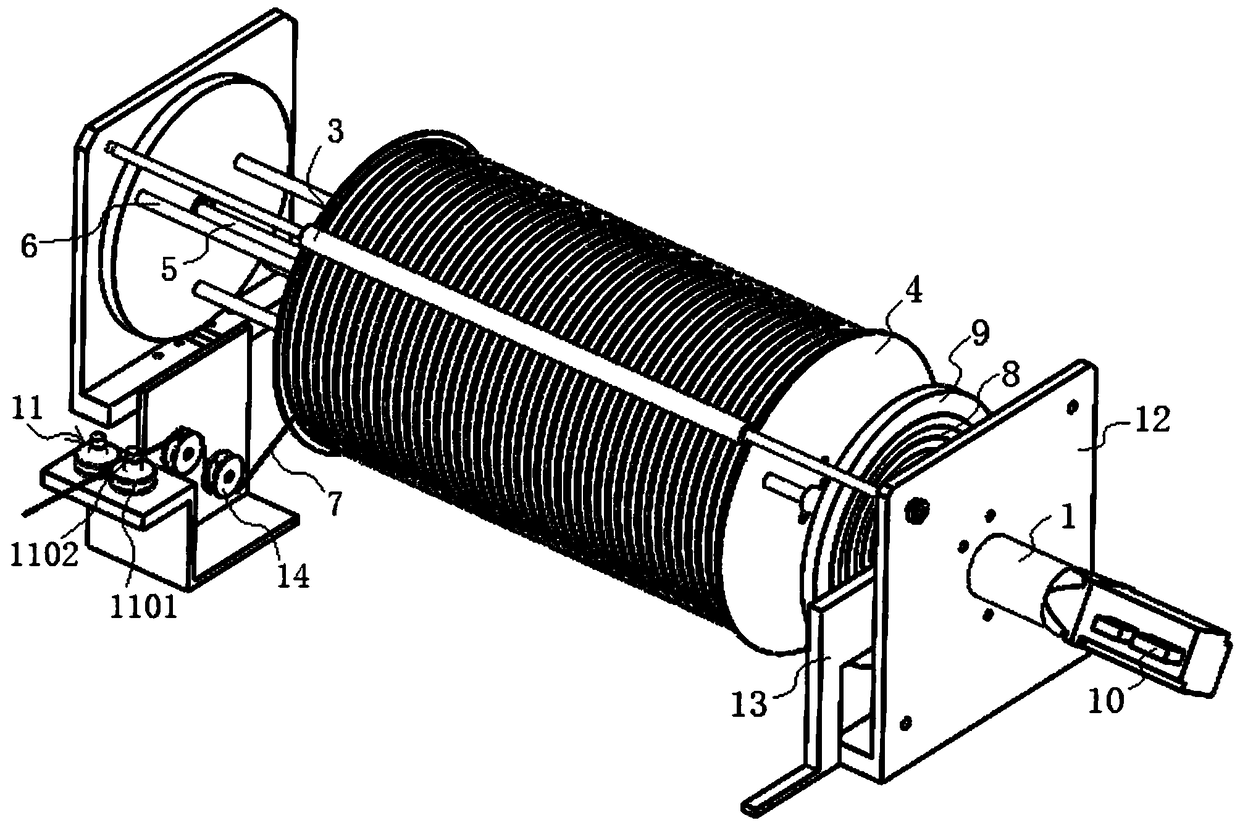

[0041] Such asfigure 1 with figure 2 As shown, a shuttle car power supply device includes a support 12 and a wire-wound conductive mechanism. The support 12 is fixed on the pallet of the hoist, and the wire-wound conductive mechanism is arranged in the middle of the support 12. Specifically, the wire-wound conductive mechanism includes The winding drum 4 is wound with an electric wire 7, and the other end of the electric wire 7 is connected to the shuttle car to supply power to the shuttle car. This design gets rid of the original battery power supply used by the shuttle car, and removes the disadvantages of regular battery replacement. However, for a large-scale shuttle storage system, a shuttle car may travel a longer distance from the elevator pallet to transport the goods, so a longer wire 7 is required, so compared with the battery car mentioned in the background technology The charging power supply device is far from being able to realize the power supply mode of the s...

Embodiment 2

[0048] Such as figure 2 As shown, a power supply device for a shuttle car in this embodiment has basically the same structure as that in Embodiment 1. Furthermore, in this embodiment, in order to facilitate the detection of the electric wire 7 by the sensing device 11, a Two guide wheels 14, the axis of two guide wheels 14 and the axis of two guide wheels 1101 are perpendicular, and electric wire 7 passes through the guide of guide wheels 14 after pulling out from winding drum 4, passes through in two guide wheels 1101. However, the design is reasonable, which is more conducive to pulling out the wire 7 and cooperating with the sensing device 11.

Embodiment 3

[0050] Such as figure 1 with figure 2 As shown, a shuttle car power supply device in this embodiment includes a support 12 and a wire-wound conductive mechanism, and also includes a motor 1, and the motor 1 is rotationally connected with the wound wire conductive mechanism; the support 12 on the side away from the motor 1 A lead screw 5 is fixedly connected, and the lead screw 5 is threadedly connected with the winding wire mechanism; it also includes a sensing device 11 and an encoder 10, the encoder 10 is connected with the motor 1, and the wire 7 on the winding wire mechanism runs through the sensing device 11 and extend outward.

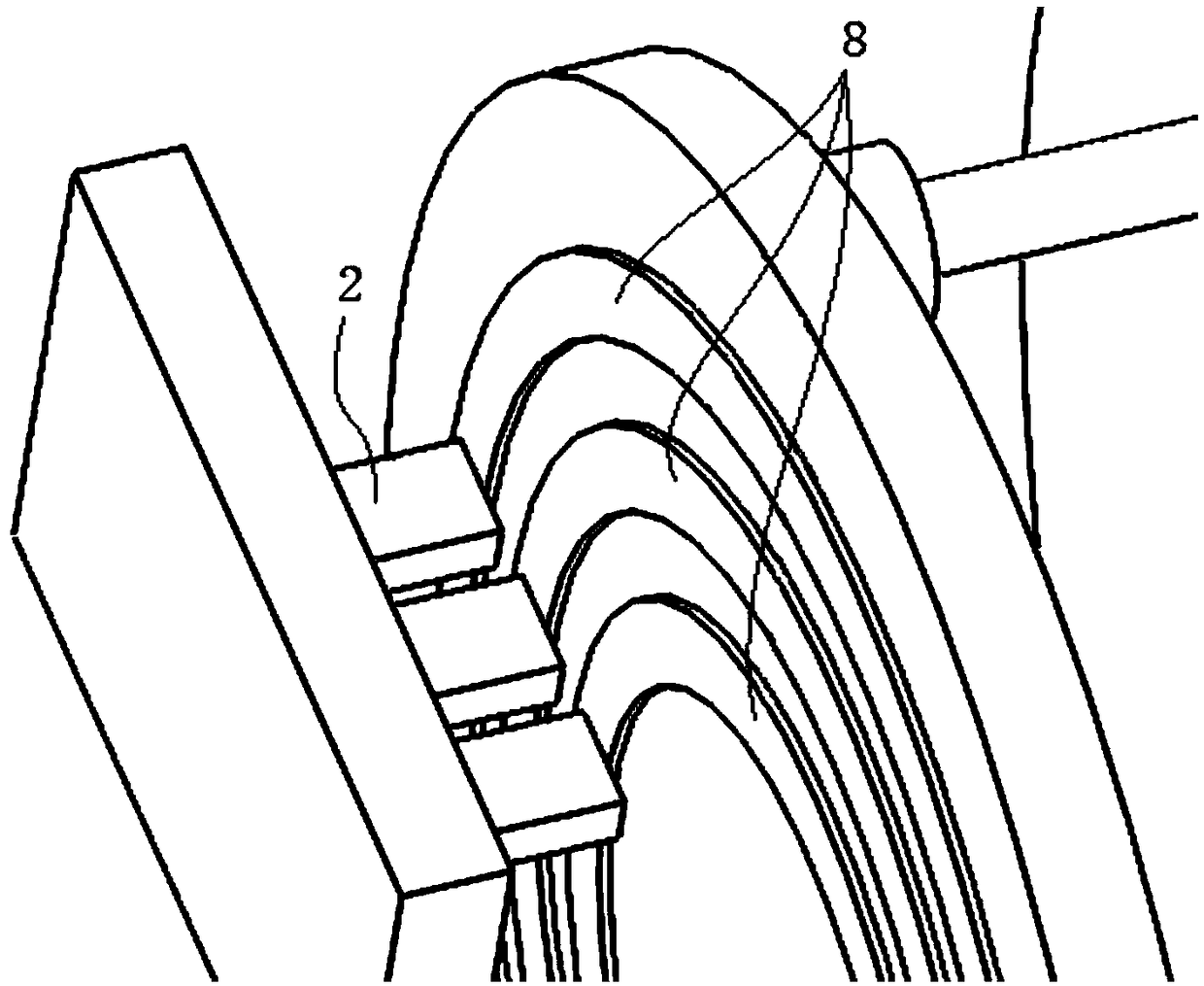

[0051] In the power supply device of this embodiment, the winding conductive mechanism includes a winding drum 4, a three-claw carbon brush 2 and three copper rings 8, and the three-claw carbon brush 2 is fixedly arranged on the support 12 through a bracket 13. The three-claw carbon brush 2 The input end of the external power supply, in which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com