Clamping device

A clamping device and clamping technology, applied in textiles and papermaking, continuous winding spinning machines, spinning machines, etc., can solve the problems of insufficient clamping effect, clamping yarn, troublesome removal of winding, etc., to achieve The effect of no residual tube underwinding and reliable clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

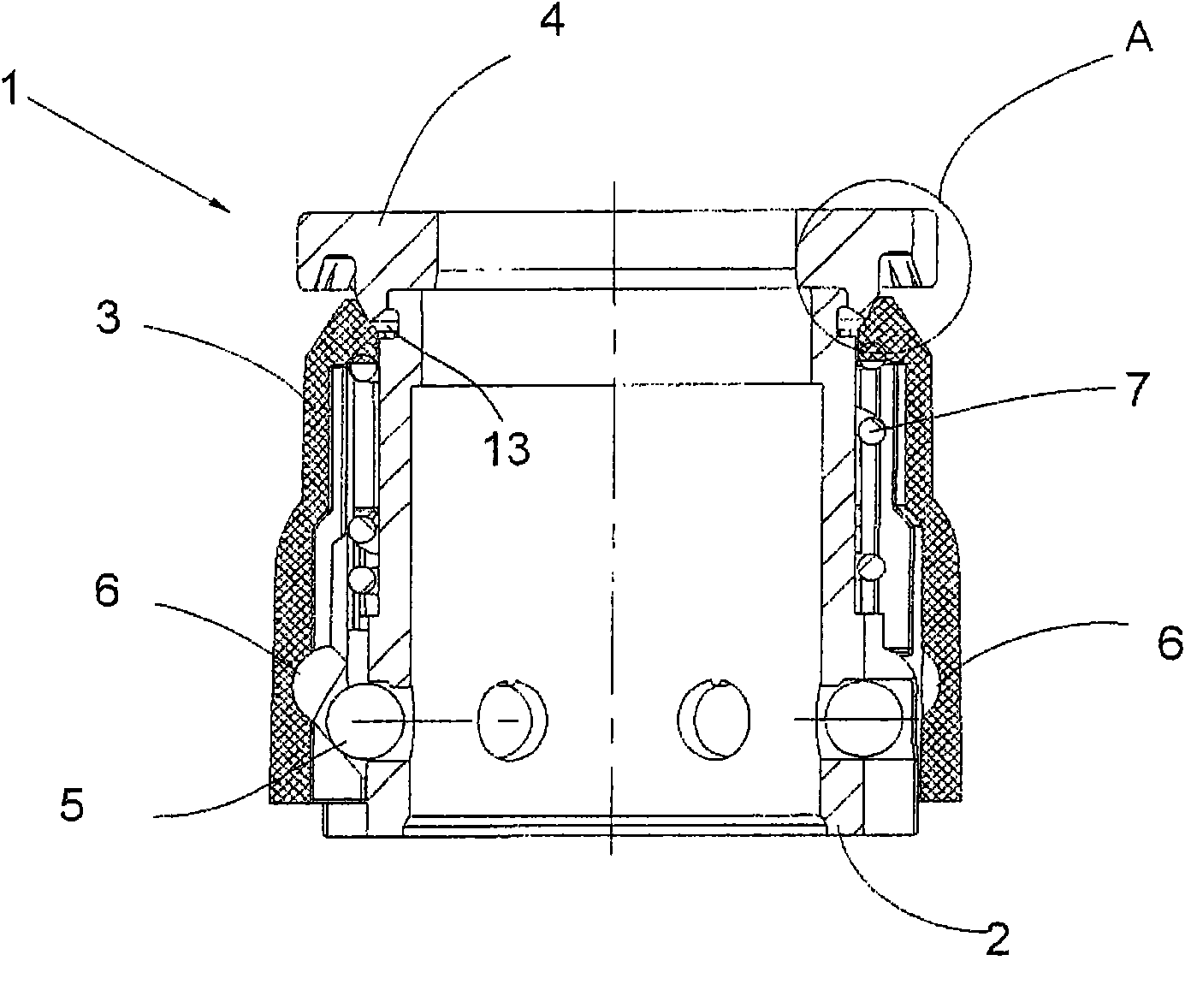

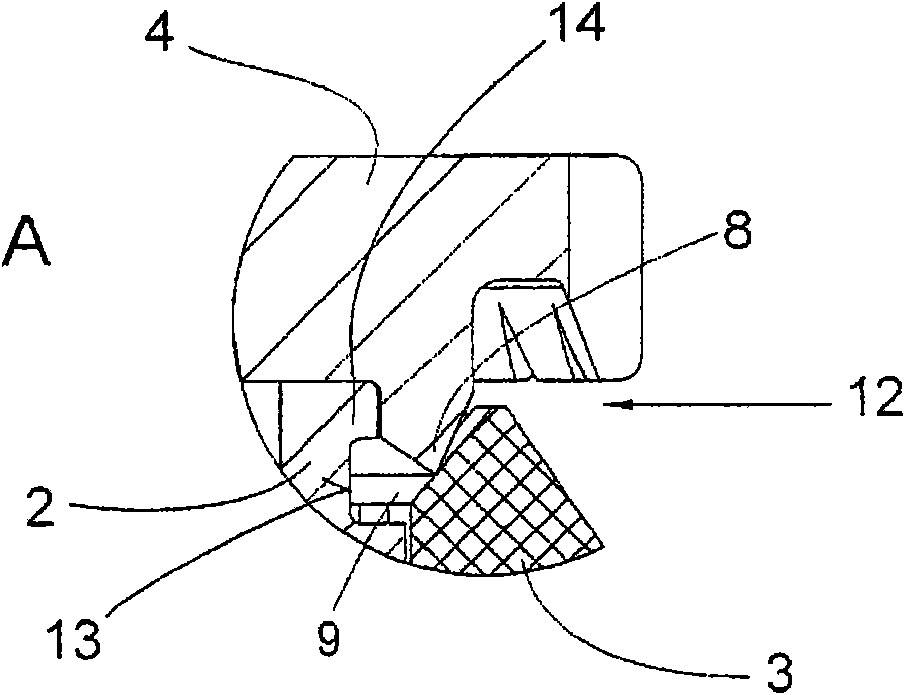

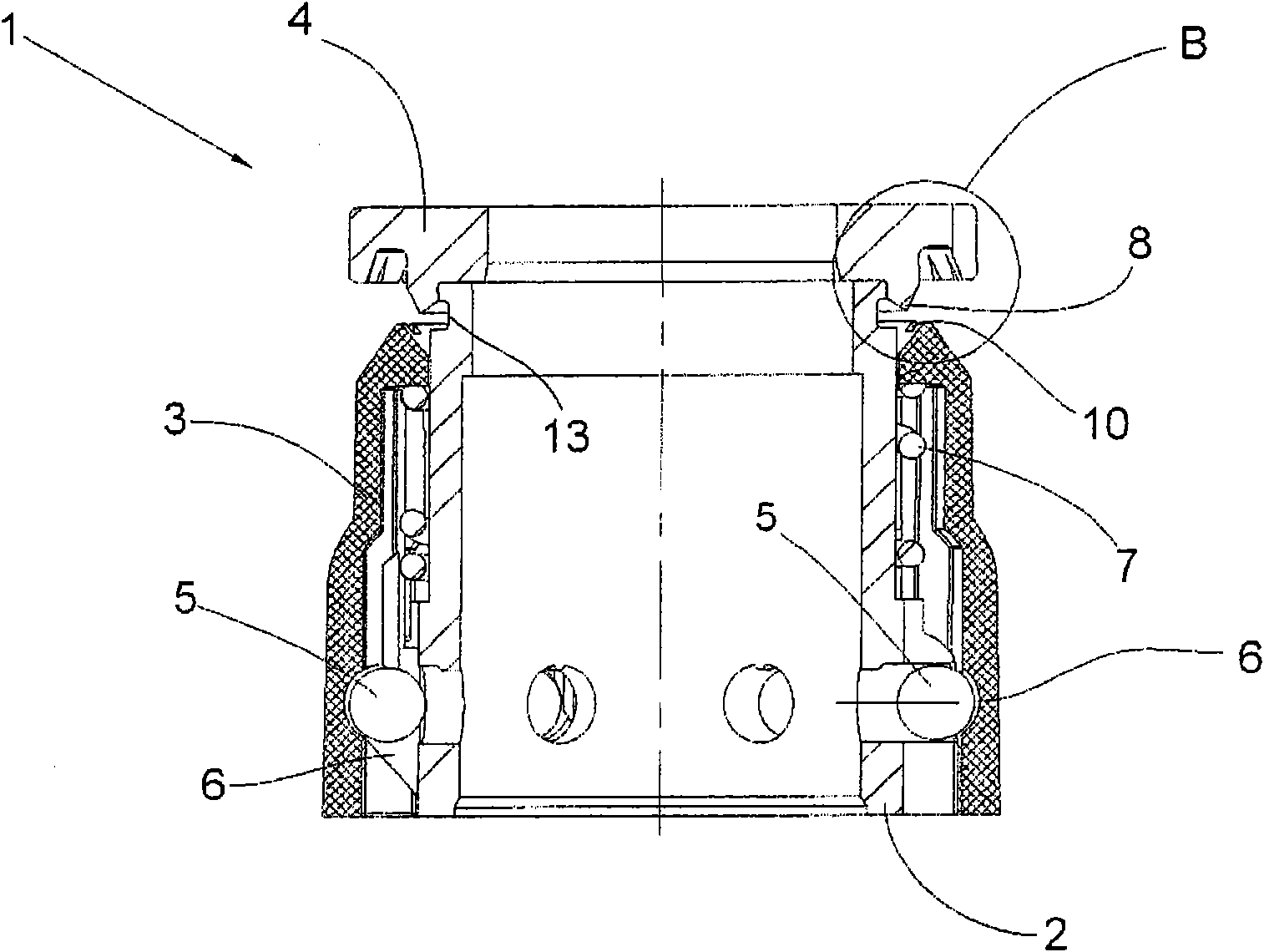

[0030] figure 1 A clamping device 1 is shown, which can be attached to the upper part of a spindle for a spinning or twisting machine or to the drive spindle of the spindle. The clamping device 1 according to the invention is used, for example, for clamping yarns during winding of finished bobbins. figure 1 The clamping device 1 shown is actuated by centrifugal force and can assume two positions - a clamped position and an open position, wherein, as figure 1 Shown in the clamping position the yarn is clamped between two clamping elements, while in the open position (eg image 3 shown) can feed the yarn or can release and throw out the previously clamped yarn.

[0031] The clamping device 1 comprises a tube bottom winding sleeve 2 which is arranged on a spindle or on a spindle (the spindle is arranged on the spindle). Furthermore, the clamping device 1 has a sliding sleeve 3 which is displaceable relative to the underwinding sleeve 2 in the longitudinal direction of the spin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com