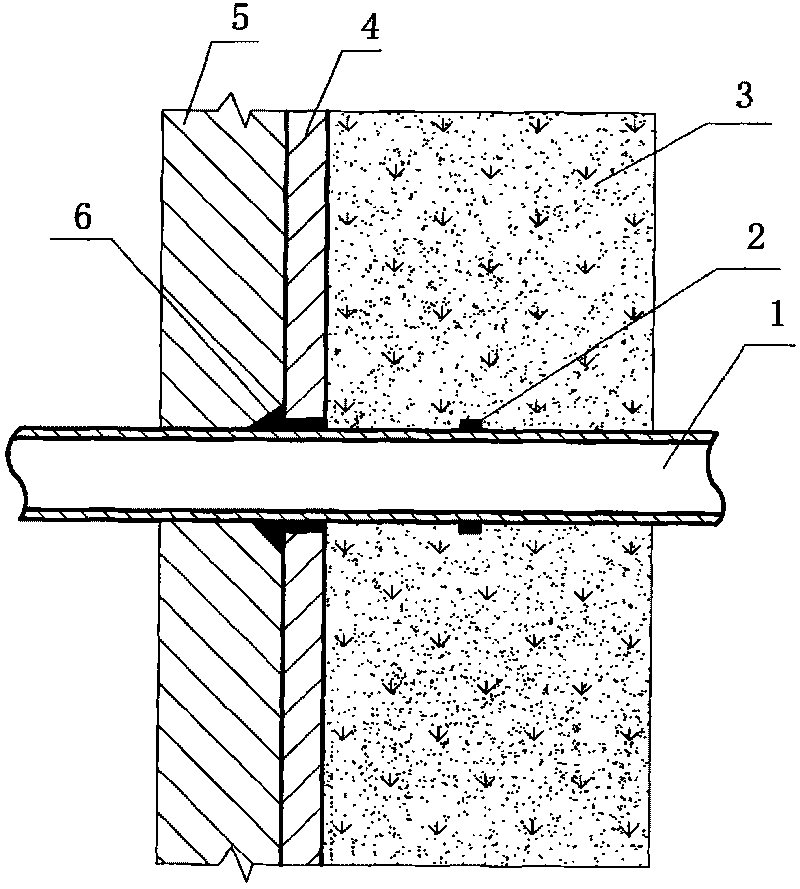

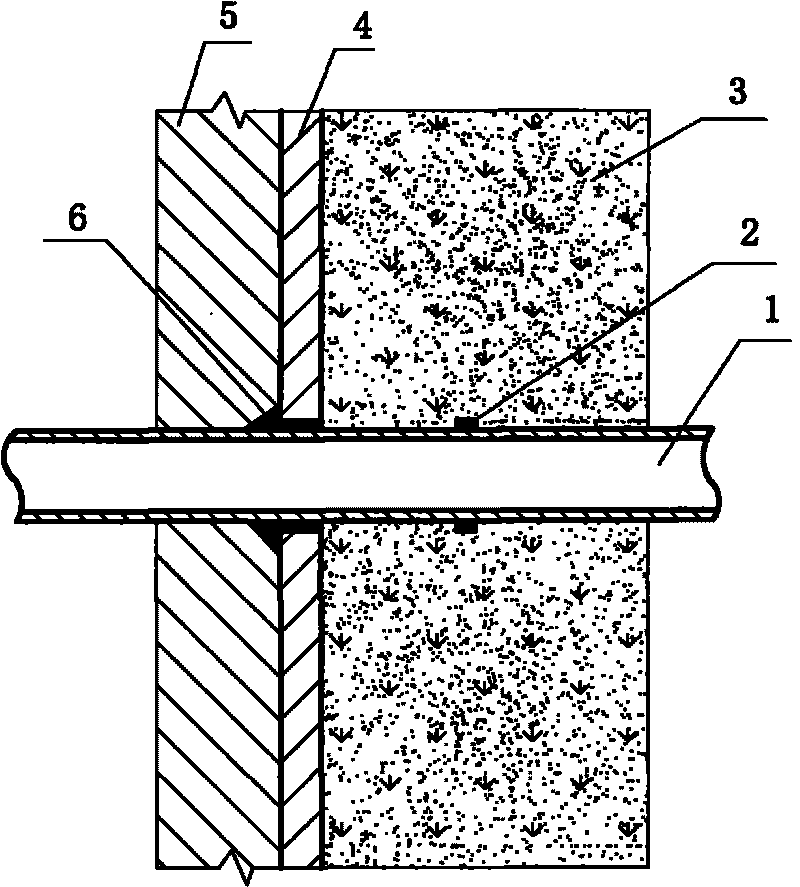

Construction method of bentonite waterproof blankets

A technology of bentonite waterproof blanket and construction method, which is applied in basic structure engineering, protection device, construction and other directions to achieve the effects of simple installation, strong water resistance and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

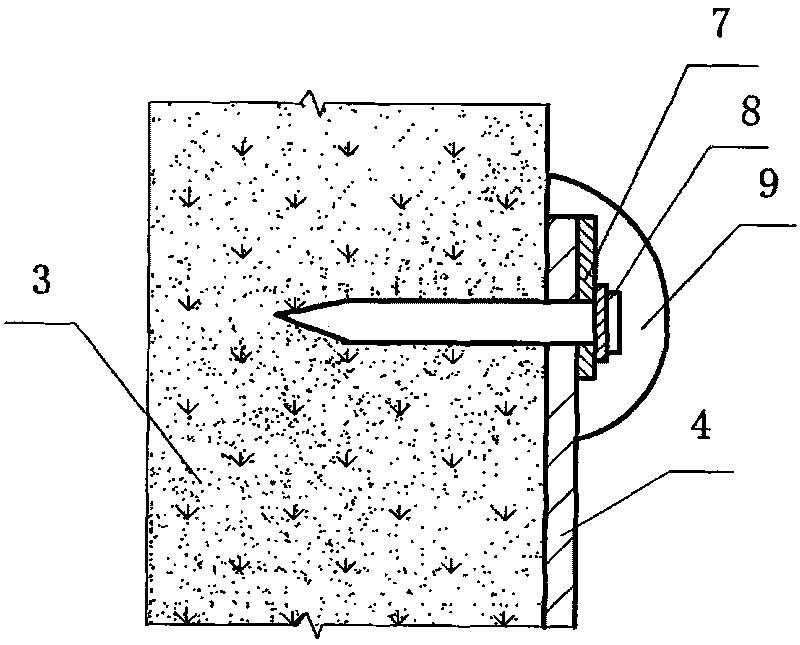

Method used

Image

Examples

Embodiment 1

[0039] Embodiment one: the construction method of bentonite waterproof blanket of the present invention, the main steps are as follows:

[0040] (1) Base surface treatment

[0041] Base surface treatment should be carried out before laying / hanging, including base surface leakage water treatment and base surface flatness treatment.

[0042] 1. The treatment of base surface leakage water shall meet the following requirements:

[0043] The base layer to be laid should be rigid, such as concrete or cement mortar, the concrete strength grade should not be less than C15, and the cement mortar strength grade should not be lower than M7.5. The base surface after treatment is allowed to be wet, but there must be no point-shaped water leakage or linear water flow;

[0044] The treatment of seepage water on the base surface should mainly focus on plugging, and if it is difficult to plug, temporary drainage measures can be taken. The temporary drainage pipe used should be embedded in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com