Wavelength conversion device and related light emitting device thereof

A technology of wavelength conversion device and wavelength conversion material, which is applied to lighting devices, fixed lighting devices, components of lighting devices, etc., can solve the problems of reduced thermal conductivity of the reflective layer and reduced luminous efficiency of the light-emitting layer, etc. Small incident depth, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

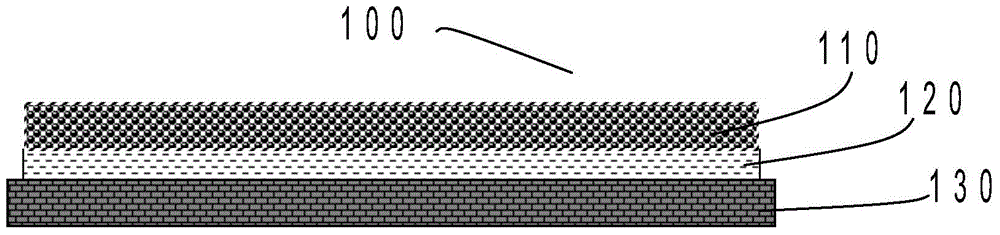

[0032] See figure 1 , figure 1 It is a schematic structural diagram of Embodiment 1 of the wavelength conversion device of the present invention. As shown in the figure, the wavelength conversion device 100 includes a substrate 130 , a light emitting layer 110 , and a reflective layer 120 . Wherein, the reflective layer 120 includes reflective particles, auxiliary particles and a first binder, and the light emitting layer 110 includes a wavelength conversion material and a second binder.

[0033] As described in the background technology, the light emitted by the light-emitting layer is incident on the reflective layer, and is reflected back to the light-emitting layer. The heat generated by the light-emitting layer is conducted to the substrate through the reflective layer, and then dissipated.

[0034] In the wavelength conversion device 100, the reflective layer 120 has two functions, one is light reflection, and the other is heat conduction. The reflective layer 120 need...

Embodiment 2

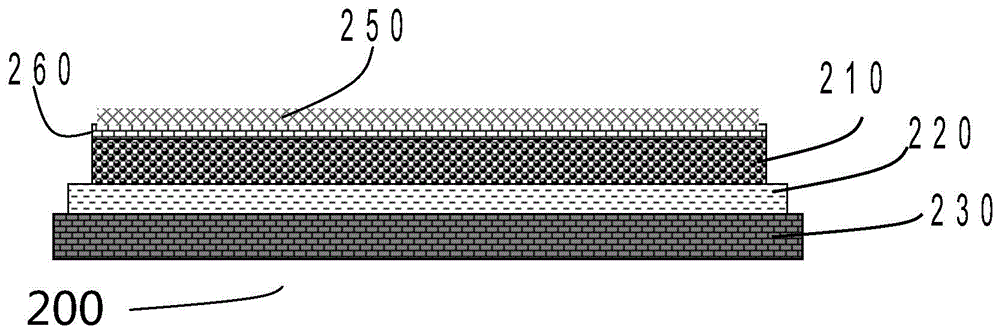

[0056] See figure 2 , figure 2 It is a schematic structural diagram of Embodiment 2 of the wavelength conversion device of the present invention. The light-emitting layer 210 , the reflective layer 220 and the substrate 230 in the wavelength conversion device 200 of this embodiment are the same as those in Embodiment 1, and details will not be repeated in this embodiment. The difference from Example 1 is that, if figure 2 As shown, the wavelength conversion device 200 further includes a glass layer 260 and an antireflection film 250 .

[0057] The glass layer 260 is located on the light emitting layer 210 and is composed of a third glass frit. Since there may be a small amount of wavelength conversion material particles protruding from the surface of the luminescent layer 210, coating on this surface may cause unevenness of the film layer, and if the luminescent layer is polished and then coated, the luminescent layer may be damaged during the grinding and polishing proc...

Embodiment 3

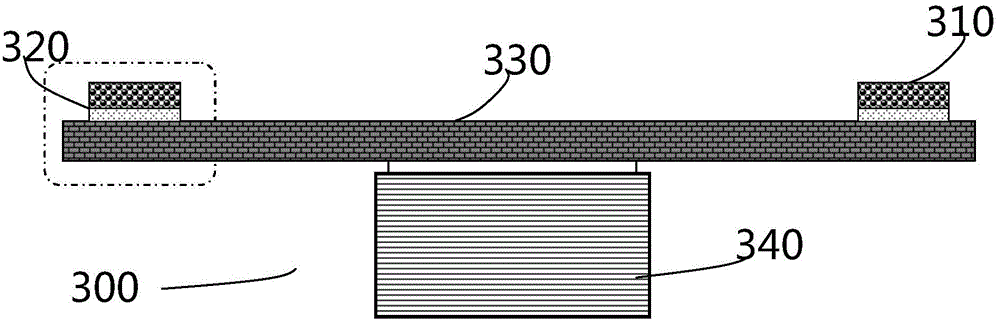

[0061] See image 3 , image 3It is a structural schematic diagram of Embodiment 3 of the wavelength conversion device of the present invention. The light-emitting layer 310 , the reflective layer 320 and the substrate 330 in the wavelength conversion device 300 of this embodiment are the same as those in Embodiment 1, and details will not be repeated in this embodiment. Different from Embodiment 1, this embodiment further includes a driving device 340, specifically, the driving device 340 in this embodiment is a motor. The substrate 330 in this embodiment is a circular substrate, carrying a circular reflective layer 320 and a light emitting layer 310 . The driving device 340 is fixedly connected with the substrate 330. When the driving device 340 rotates, it drives the substrate 330, the reflective layer 320 and the luminescent layer 310 on it to rotate together, so as to prevent the excitation light of the excitation light source from irradiating a point on the luminescent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com