High low temperature resistant oil-retaining bearing made of powder metallurgy material and manufacturing method thereof

A technology of powder metallurgy, high and low temperature resistance, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of reducing the friction coefficient of materials, restricting the automation industry, etc., and achieve the effect of low manufacturing cost and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

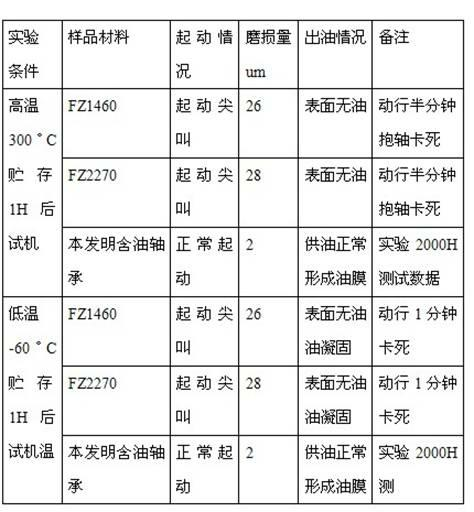

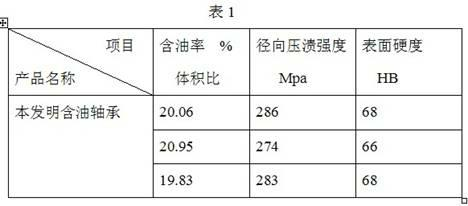

Examples

Embodiment 1

[0020] (1) Prepare raw materials: take raw materials according to the following weight percentages: -100 mesh graphite powder 35%, -100 mesh copper powder 35%, -100 mesh iron powder 30%,

[0021] (2) Electroplating coating, electroplating -100 mesh copper powder on the surface of graphite powder at a ratio of 1:1;

[0022] (3) Mixing: Fully mix the electroplated graphite and iron powder evenly, and the mixing time is at least 1h.

[0023] (4) Molding and pressing: Screen the mixed material through a 100-mesh sieve to remove the powder that cannot pass through, then put the sieved mixed material into the hopper of the molding machine, adjust the molding mold, pressurize to 400Mpa, and the pressing density is 6.4 -6.5g / m 3 .

[0024] (5) Reduction sintering: Put the pressed blank into a high-temperature mesh belt electric furnace for reduction sintering. The speed of the mesh belt is 54~60mm / min. The low temperature zone is the preheating zone, and its temperature is 580~600°C...

Embodiment 2

[0029] (1) Prepare raw materials: take raw materials according to the following weight percentages: -100 mesh graphite powder 40%, -100 mesh copper powder 40%, -100 mesh iron powder 20%,

[0030] (2) Electroplating coating, electroplating -100 mesh copper powder on the surface of graphite powder at a ratio of 1:1;

[0031] (3) Mixing: Fully mix the electroplated graphite and iron powder evenly, and the mixing time is at least 1h.

[0032] (4) Molding and pressing: Screen the mixed material through a 100-mesh sieve to remove the powder that cannot pass through, then put the sieved mixed material into the hopper of the molding machine, adjust the molding mold, pressurize to 400Mpa, and the pressing density is 6.4 -6.5g / m 3 .

[0033] (5) Reduction sintering: Put the pressed blank into a high-temperature mesh belt electric furnace for reduction sintering. The speed of the mesh belt is 54~60mm / min. The low temperature zone is the preheating zone, and its temperature is 580~600°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com