Aqueous composite zinc-aluminum anticorrosion coating

An anti-corrosion coating, zinc-aluminum technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of weak scratch resistance, high carcinogenicity, human health threats, etc., to improve mechanical properties, corrosion resistance, and good dispersibility and stability, the effect of improving storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

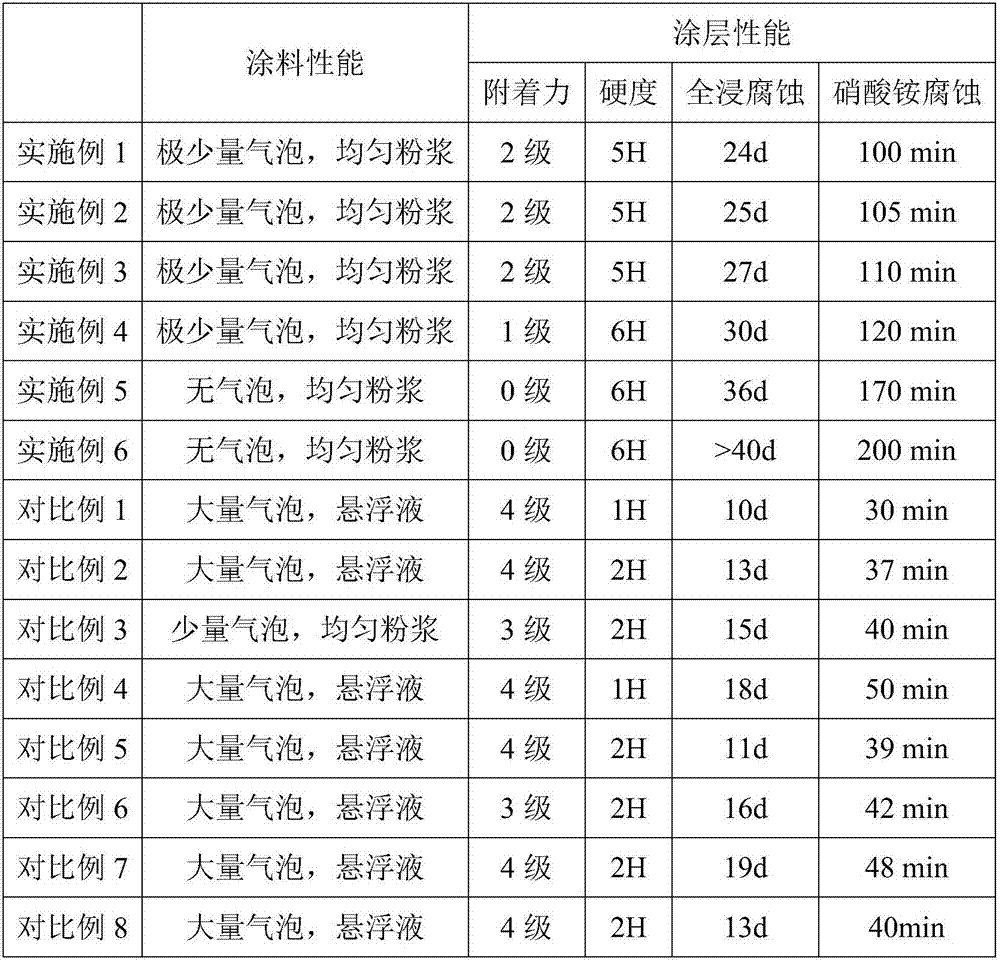

Examples

preparation example Construction

[0102] As a kind of preferred technical scheme of the present invention, the preparation method of described modified graphene at least comprises the following steps:

[0103] a. Take graphite powder and add dissolved K 2 S 2 o 8 and P 2 o 5 Graphite powder, K 2 S 2 o 8 ,P 2 o 5 The mass ratio of sulfuric acid and sulfuric acid is 2:1:1:5, stirred and cooled to room temperature naturally, diluted with deionized water, filtered, washed with water until neutral, and the product was dried in air; the above product was added to 18mol / L of ice bath In sulfuric acid, gradually add KMnO during stirring 4 , graphite powder, sulfuric acid and KMnO 4 The mass ratio of the graphite powder is 1:36:3, and the reaction temperature is controlled within 15°C; then the mixture is transferred to a water bath at 35°C, and deionized water is gradually added. The mass of deionized water is 45 times that of graphite powder, and the reaction is stirred for 2 hours. Then add deionized wate...

Embodiment 1

[0139] Embodiment 1 provides a kind of water-based composite zinc-aluminum anticorrosion paint, by weight, at least includes the following raw materials:

[0140] Zinc-aluminum alloy powder: 40 parts by weight,

[0141] Passivator: 2 parts by weight,

[0142] Binding agent: 10 parts by weight,

[0143] Dispersant: 25 parts by weight,

[0144] Wetting agent: 0.5 parts by weight,

[0145] Filler: 5 parts by weight,

[0146] Auxiliary agent: 0.5 parts by weight,

[0147] Solvent: 100 parts by weight;

[0148] The content of aluminum in the zinc-aluminum alloy powder is 15wt%, and the grade is Scott Chemical Co., Ltd. AZ-15; the passivator is sodium phosphomolybdate; the binder is γ-glycidol Etheroxypropyltriethoxysilane; the dispersing agent is polyoxyethylene sorbitan laurate, the trade mark is Guangdong Runhua Chemical Co., Ltd. Tween 20; the wetting agent is polyethylene glycol 6000; the filler is a mixture of nano-titanium dioxide and modified graphene, the weight rati...

Embodiment 2

[0160] Embodiment 2 provides a kind of water-based composite zinc-aluminum anticorrosion paint, by weight, at least includes the following raw materials:

[0161] Zinc-aluminum alloy powder: 65 parts by weight,

[0162] Passivator: 5 parts by weight,

[0163] Binding agent: 18 parts by weight,

[0164] Dispersant: 45 parts by weight,

[0165] Wetting agent: 5 parts by weight,

[0166] Filler: 15 parts by weight,

[0167] Auxiliary agent: 2 parts by weight,

[0168] Solvent: 100 parts by weight;

[0169] The content of aluminum in the zinc-aluminum alloy powder is 15wt%, and the grade is Scott Chemical Co., Ltd. AZ-15; the passivator is sodium phosphomolybdate; the binder is γ-aminopropyl Triethoxysilane; the dispersant is polyoxyethylene sorbitan laurate, and the trade mark is Guangdong Runhua Chemical Co., Ltd. Tween 20; the wetting agent is polyethylene glycol 6000; Described filler is the mixture of nano-titanium dioxide and modified graphene, and the weight ratio of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com