Improved electric grain screening machine

A screening machine and grain technology, applied in the field of agricultural machinery, can solve the problems of low efficiency, time-consuming and laborious, high labor cost, etc., achieve the effect of complete separation, reduce labor cost, and speed up screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

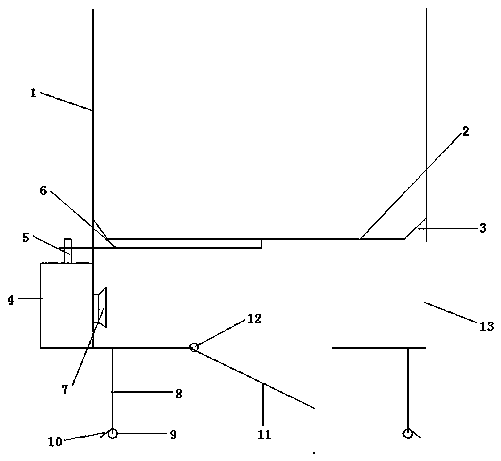

[0013] Example: such as figure 1 As shown, an improved grain electric screening machine includes a cylindrical body 1 made of stainless steel plate, which is characterized in that: the top of the body 1 is open for dumping the grains to be screened, and a circular discharge is arranged in the middle of the bottom of the body 1 The edge of the discharge port is provided with a baffle 11, the baffle 11 is connected to the bottom of the body 1 through a rotating shaft 12, a screen 2 is arranged in the middle of the body 1, and the screen 2 is fixed on the inner wall of the body 1 through a flexible belt 3 , the outside of the body 1 is also provided with a motor 4, the rotating shaft 5 of the motor 4 is connected to the middle position of the bottom of the screen 2 through the transmission rod 6, and the body 1 is located at the bottom of the screen 2. The inner wall is provided with a fan 7, and the fan 7 has an air outlet A leather outlet 13 is provided at the corresponding pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com