Husk and seed separating device of corn husker

A technology for separating and peeling skin and seeds, which is applied in agricultural machinery and implements, threshing equipment, applications, etc., can solve the problems of poor cleanliness, high labor intensity, waste, etc., and achieve the effect of complete separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

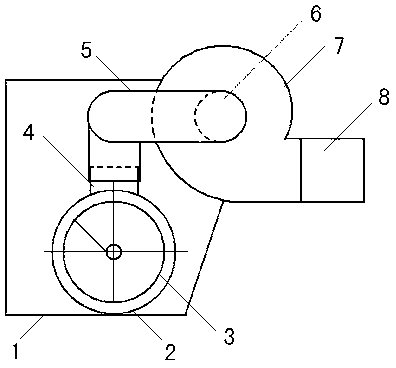

[0020] like figure 1 As shown, the peeling device of the corn peeling machine, the peeling machine 1 includes a power transmission mechanism, a stirring drum 2, an auger 3 is arranged in the stirring drum 2, and a skin outlet is characterized in that: the cylinder wall at the outlet of the stirring drum On the top, a nozzle 4 is provided, and the nozzle 4 is connected to the air inlet 6 of the exhaust fan 7 through the air pipe 5 .

[0021] At the lower part of the outlet of the mixing drum, several seed leaking holes are arranged, and the seed leaking holes are used for draining corn seeds.

[0022] The diameter of the mouth of the nozzle is set on the basis that the corn husk can be removed smoothly, generally it can be set to 15-50 cm, preferably 20-35 cm.

[0023] The setting of the hole diameter of the leaking seed hole is subject to the smooth leakage, and generally can be set to 1.5-4 cm, preferably 2-3 cm.

[0024] During use, when the peeled skin is from the mixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com