Iron removal device for acid-containing copper sulfate solution

A copper sulfate solution and locking device technology, applied in the field of water treatment, can solve the problems of high practical application cost of membrane separation technology, easy pollution of membrane components, and short service life of membrane, so as to reduce the amount of sludge produced and improve the environment Benefit and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

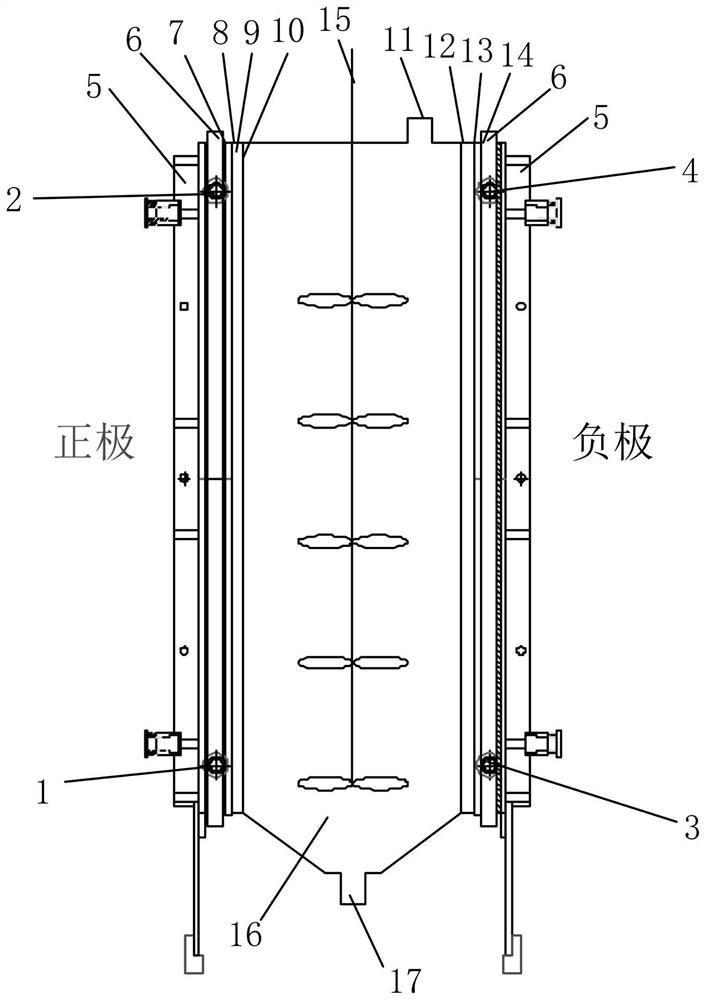

[0031] Process a length of 60cm, width of 70cm, and height of 120cm iron removal device, including positive electrode plate 8, negative electrode plate 14, wherein the two sides of iron removal chamber 16 are respectively placed with anode porous plate 10 and cathode porous plate 12; The perfluorosulfonic acid positive membrane 9, the positive electrode plate 8, the water distribution network 7 in the pole chamber, the water distribution plate 6, and the locking device 5 are placed in sequence on the outside of the anode porous plate 10; the bipolar membrane 13 is placed on the outside of the cathode porous plate 12, and the The electrode plate 14, the pole chamber water distribution network 7, the water distribution plate 6, and the locking device 5; the locking device 5 fixes the whole device through the water distribution plates 6 on the two outer sides, and is in the shape of a cuboid.

[0032] An anolyte inlet 1 is installed on the lower part of the water distribution plat...

Embodiment 2

[0036] The device is as in Example 1, with a chemical dosing port 11 installed at the top of the iron removal chamber 16, a mixer 15 with constant temperature heating installed in the middle, and an iron sludge discharge port 17 installed at the bottom.

[0037]Close the valve of the iron slime discharge port 17, add waste acid containing 80g / L of iron and 30g / L of copper sulfate concentration and 40g / L of sulfuric acid concentration through the dosing port 11 through the dosing port 11, and the volume added should reach the iron removal chamber 16 95% by volume. The liquid temperature is heated to 35° C. by means of a stirrer 15 with constant temperature heating. The anode chamber is equipped with 1% sulfuric acid solution, the cathode water tank is equipped with 6% sulfuric acid solution, the magnetic pump of the cathode and anode is started to make the circulation flow rate 1.2t / h, and a direct current is applied to the cathode and anode electrodes, the operating voltage is...

Embodiment 3

[0040] The device is as in Example 2.

[0041] Close the valve of the iron sludge discharge port 17, and add waste acid containing 20 g / L of iron and 100 g / L of copper sulfate concentration and 120 g / L of sulfuric acid concentration through the dosing port 11 through the dosing port 11, and the added volume should reach the iron removal chamber (16) 95% by volume. The liquid temperature is heated to 35° C. by means of a stirrer 15 with constant temperature heating. The anode chamber is equipped with 2% sulfuric acid solution, the cathode water tank is equipped with 7% sulfuric acid solution, the magnetic pump of the cathode and anode is started to make the circulation flow rate 1.5t / h, and a direct current is applied to the cathode and anode electrodes, the operating voltage is 35V, and the operating current is 350A. Deacidification is carried out by electrification, and when the pH of the solution in the iron removal chamber 16 is adjusted to 0.6, the electrification is stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com