Rice ultra-separation impurity removing device

A technology of rice and sieve boxes, which is applied in the direction of solid separation, sieve, grid, etc., can solve the problems of unsatisfactory separation effect, low separation efficiency, and a small amount of impurities in rice, and achieve high working efficiency, small size and thorough separation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

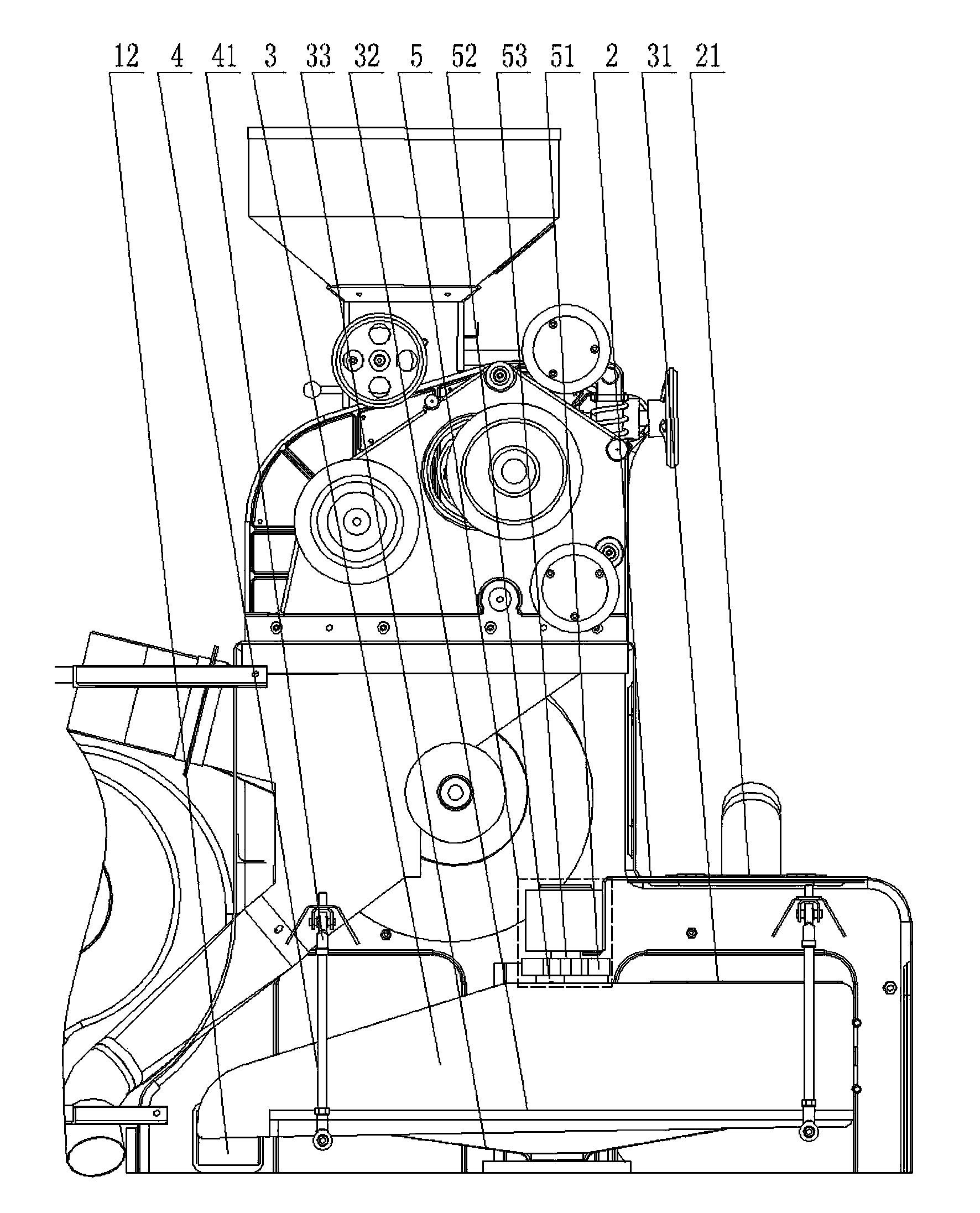

[0012] figure 1 It is a structural representation of the present invention. Depend on figure 1 As can be seen, this rice ultra-separation impurity removal device is mainly composed of frame 2, sieve box 3 and the like. The top of the frame 2 is provided with a feed inlet 21, a sieve box 3 is hoisted under the feed inlet 21, and a miscellaneous outlet 12 is provided at the left end of the sieve box 3. The right end of the top of the sieve box 3 is provided with a sieve box feed port 31 corresponding to the feed port 21 . The bottom of the sieve box 3 is provided with a sieve plate 32, the bottom of the sieve plate 32 is provided with a drop hopper 33 connected with the sieve box 3, and the sieve plate 32 is a perforated fish scale screen.

[0013] The two sides of the screen box 3 are hinged with the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com