Preparation method of antioxidant 168

An antioxidant and preparation technology, applied in the field of antioxidant preparation, can solve the problems of excessive solid waste generation and difficult product refining, and achieve the effects of complete separation, excellent hydrolysis resistance and high catalyst activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

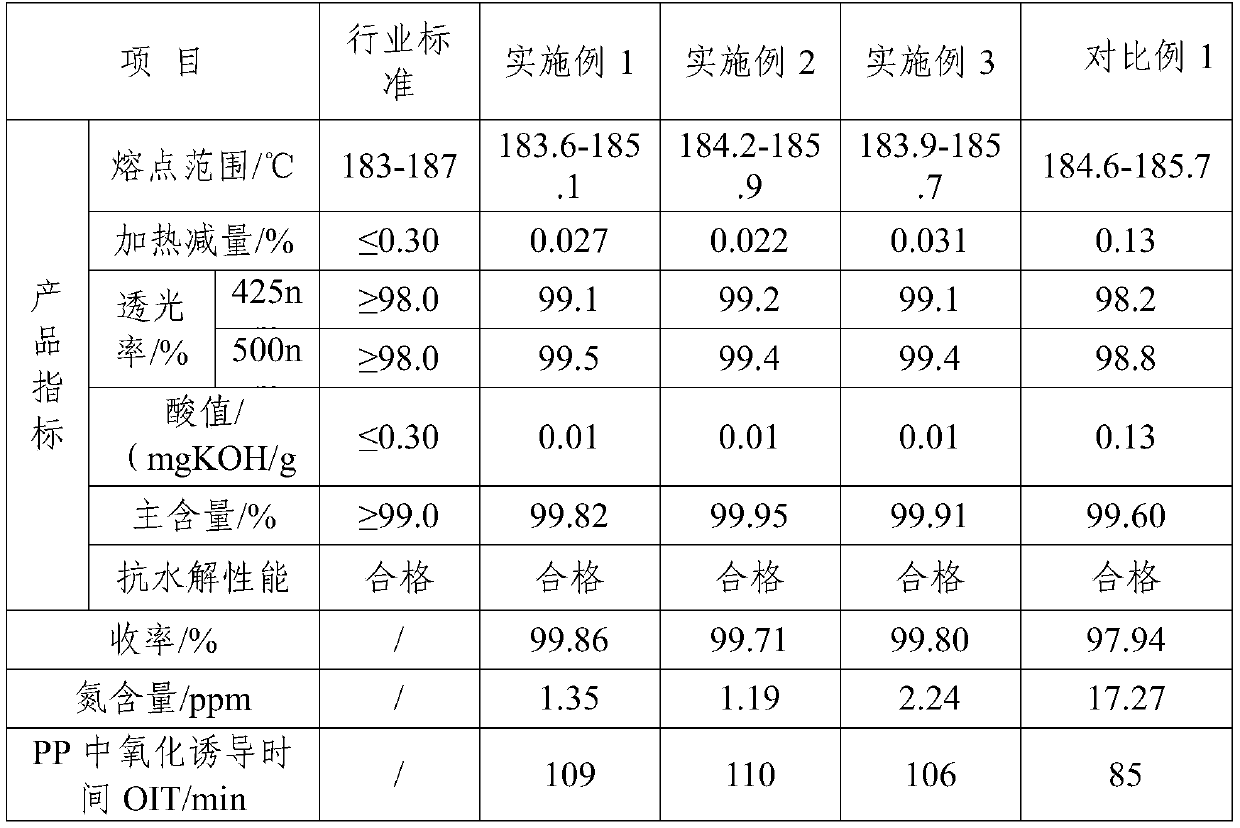

Embodiment 1

[0025] Put 646g of 2,4-di-tert-butylphenol, 410g of benzene and 40g of weak base type macroporous anion exchange resin (model D301, Hunan Zhuzhou Xiangzhong Resin Co., Ltd.) Add 137g of phosphorus trichloride dropwise for 4 hours. After the addition, raise the constant temperature to 90°C and keep the temperature for 4 hours. The HCl gas generated during the reaction process is absorbed by the falling film absorption tower. After the reaction, add a weak base macroporous anion exchange 61g of resin (type D301, Hunan Zhuzhou Xiangzhong Resin Co., Ltd.) was used as a neutralizing agent to neutralize the reaction solution to neutrality. The obtained reaction liquid was filtered, and the solid resin was filtered out; the filtrate was precipitated, washed, crystallized, filtered, and dried to obtain 644.5 g of the antioxidant 168 product.

Embodiment 2

[0027] The solid resin part separated in Example 1 was used as the catalyst prepared in 168, and the rest was regenerated by alkali washing, distilled water washing, drying, etc. and used as a neutralizer.

[0028] 628.5g of 2,4-di-tert-butylphenol, 364.5g of toluene and 55.9g of weakly basic macroporous anion exchange resin were put into the reactor, and after the temperature was raised to 46°C, 137g of phosphorus trichloride was added dropwise to the reactor, and Add for 3 hours, after the addition, raise the constant temperature to 110°C, and keep the temperature for 3 hours; the HCl gas generated during the reaction process is absorbed by the falling film absorption tower; Neutral to neutral. The obtained reaction liquid was filtered, and the solid resin was filtered out; the filtrate was precipitated, washed, crystallized, filtered, and dried to obtain 643.6 g of the antioxidant 168 product.

Embodiment 3

[0030] The solid resin isolated in Example 1 was used mechanically in 20 batches, and the part of the solid resin isolated again was the catalyst prepared by 168, and the rest were regenerated by alkali washing, distilled water washing, drying, etc. and used mechanically as a neutralizer. 653g of 2,4-di-tert-butylphenol, 457g of xylene and 51.3g of weak base type macroporous anion exchange resin were put into the reactor, and after the temperature was raised to 50°C, 137g of phosphorus trichloride was added dropwise to the reactor, and the 4h, after the addition, raise the constant temperature to 120°C, and keep the temperature for 3h; the HCl gas generated during the reaction process is absorbed by the falling film absorption tower; Neutral to neutral. The obtained reaction solution was filtered to filter out the solid resin; the filtrate was precipitated, washed, crystallized, filtered, and dried to obtain 644.2 g of the antioxidant 168 product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com