Method and special device for separating fly maggots from substrates

A special equipment and fly maggot technology, which is applied in the direction of solid separation, chemical instruments and methods, filter screens, etc., can solve the problems of low efficiency, poor cleanliness, inconsistent expansion and contraction of fly maggots, etc., and achieve high separation rate and complete separation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

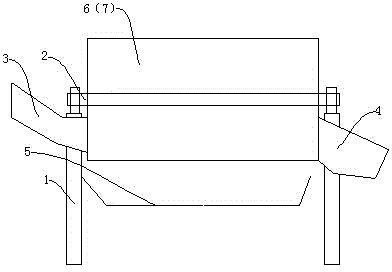

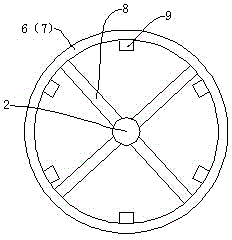

[0017] Such as figure 1 , figure 2 As shown, the special equipment for fly maggot and matrix separation described in this embodiment includes a coarse matrix separation device and a fine matrix separation device, and the coarse matrix separation device includes a coarse matrix separation net 6, a frame 1, a rotating shaft 2 and a power drive mechanism, The coarse matrix separation net 6 is a cylindrical structure, and the rotating shaft 2 is arranged on the frame 1 and is connected with the power drive mechanism. One end of the coarse matrix separation net 6 is provided with a material inlet 3, and the other end is provided with a material outlet 4, and the mesh size of the coarse matrix separation net 6 is greater than the length after the fly maggot stretches straight; the fine matrix separation device comprises a fine matrix separation net 7, The frame 1, the rotating shaft 2 and the power drive mechanism, the fine matrix separation screen 7 is a cylindrical structure, th...

Embodiment 2

[0019] Such as figure 1 , figure 2 As shown, the special equipment for fly maggot and matrix separation described in this embodiment includes a coarse matrix separation device and a fine matrix separation device, and the coarse matrix separation device includes a coarse matrix separation net 6, a frame 1, a rotating shaft 2 and a power drive mechanism, The coarse matrix separation net 6 is a cylindrical structure, and the rotating shaft 2 is arranged on the frame 1 and is connected with the power drive mechanism. One end of the coarse matrix separation net 6 is provided with a material inlet 3, and the other end is provided with a material outlet 4, and the mesh size of the coarse matrix separation net 6 is greater than the length after the fly maggot stretches straight; the fine matrix separation device comprises a fine matrix separation net 7, The frame 1, the rotating shaft 2 and the power drive mechanism, the fine matrix separation screen 7 is a cylindrical structure, th...

Embodiment 3

[0021] In the method for separating fly maggots and substrates described in this embodiment, at first the mixture of fly maggots and substrates is sent into the inside of the coarse substrate separation screen 6 through the material inlet 3, and as the coarse substrate separation screen 6 rotates, the fine substrate and fly maggots can be separated Filter and fall from the eyeholes of the coarse matrix separation net 6, and the coarse matrix of large particles is discharged from the material outlet 4; secondly, the fine matrix and fly maggots filtered out from the coarse matrix separation net 6 are sent into the fine matrix from the material inlet 3. In the matrix separation net 7, during the rotation process of the fine matrix separation net 7, the fly maggots are in a stretched state, and then the fine matrix is filtered out from the fine matrix separation net 7, while the fly maggots are in the fine matrix separation net 7, and are removed from the material. Exit 4 dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com