Old sand regenerator

A technology of sand regenerator and frame, which is applied to the cleaning/processing machinery of casting materials, casting molding equipment, metal processing equipment, etc. Low, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

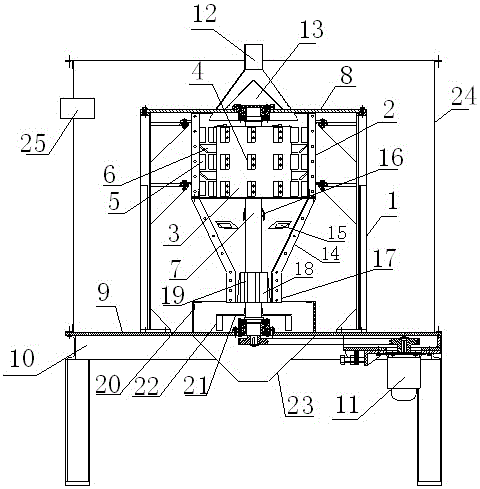

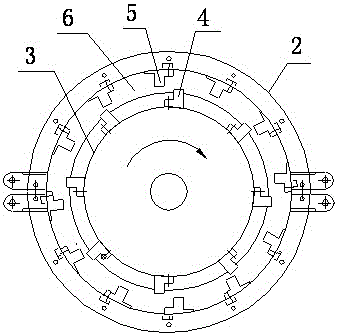

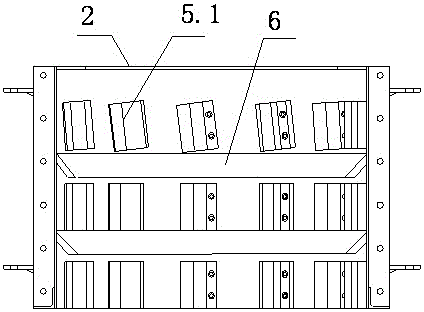

[0026] Such as figure 1 , 2 As shown, a kind of used sand reclamation machine comprises support frame 1, cylinder body 2, and cylinder body is fixed on the frame, and described cylinder body is combined by two half cylinders (such as figure 1 Shown is the state with half of the cylinder removed), and the two half cylinders are connected by bolts. A roller body 3 is coaxially arranged in the cylinder body, and a circle of striking plates 4 is arranged on the roller body from top to bottom, and each circle of striking plates is a small plate body distributed along the circumferential direction of the roller body. The plate body is "L" shaped and fixed on the roller body by bolts. A circle of striking plates 5 correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com