Copper and aluminum separating equipment of waste air conditioner heat exchanger

A separation equipment and heat exchanger technology, applied in shearing machine equipment, metal processing equipment, electronic waste recycling and other directions, can solve the problems of inconvenient practical application, high use cost, long replacement cycle, etc., to achieve convenient use and maintenance, Easy operation and complete separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

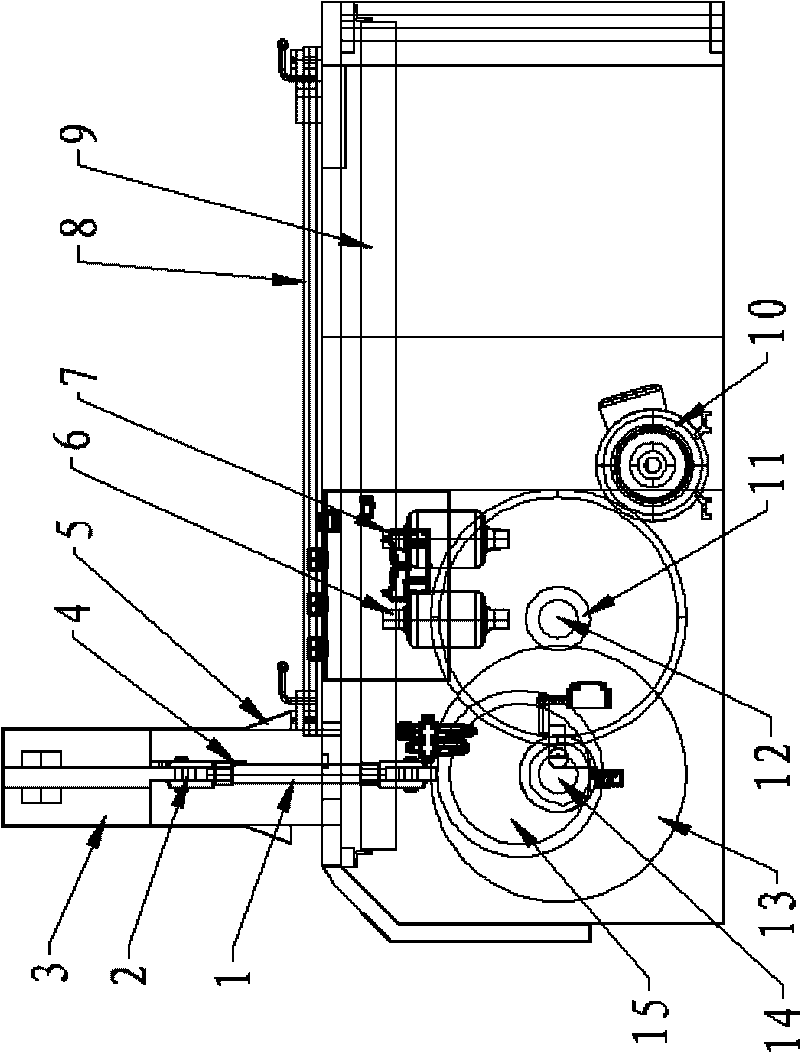

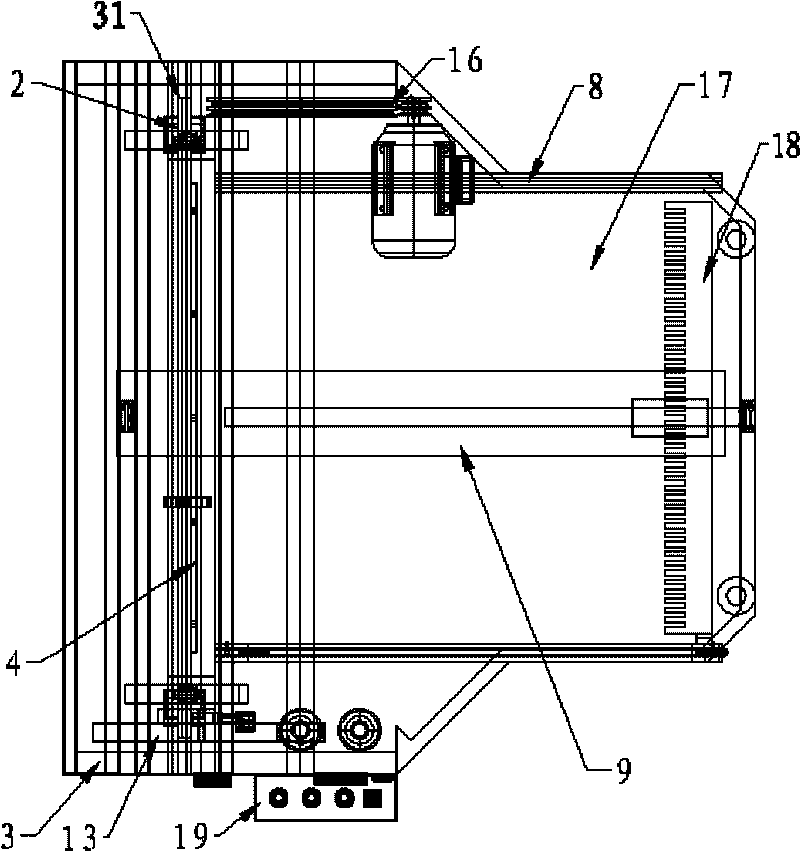

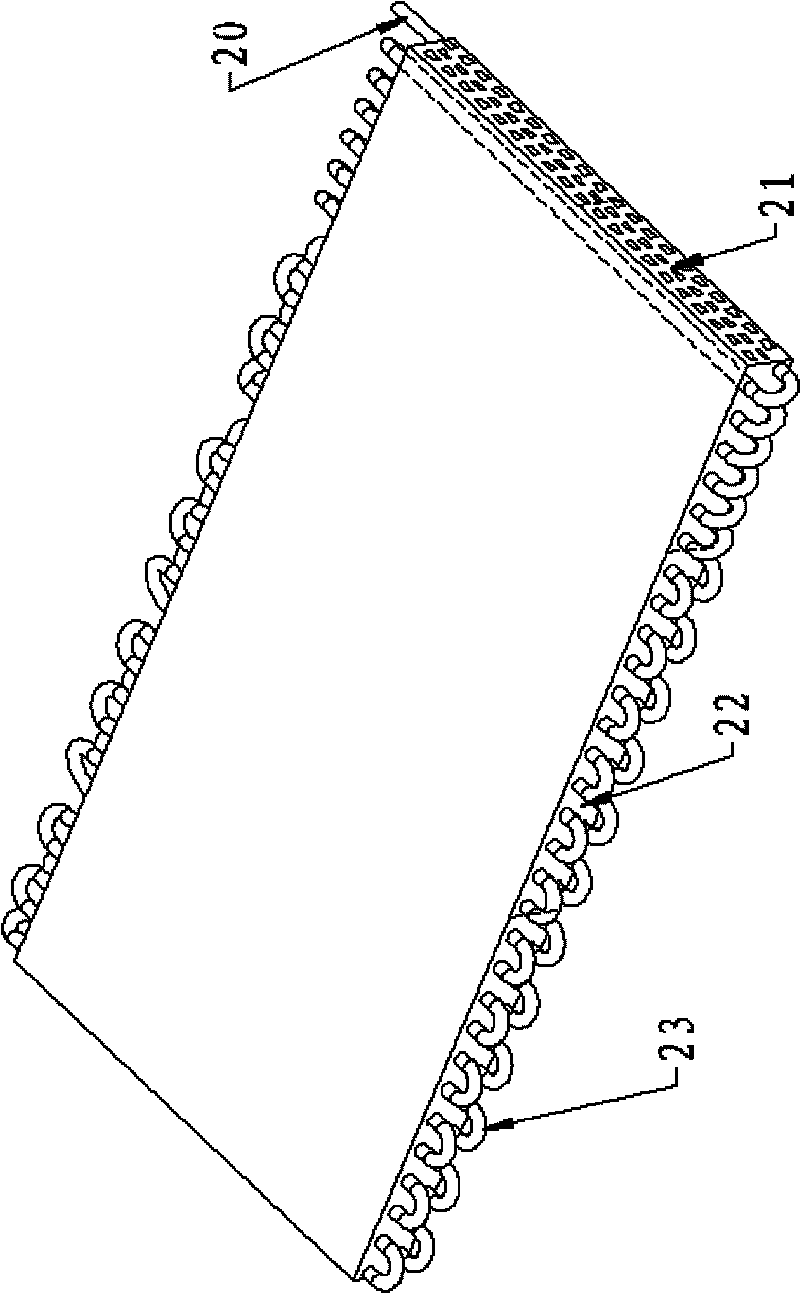

[0030] Such as figure 1 with figure 2 , The heat exchanger copper-aluminum separation equipment of the present invention specifically includes: a frame 3, a workbench 17, a cutting mechanism, a feeding mechanism and a control system. The frame 3 is used as an installation, fixing and protection structure for other components, and the workbench 17 is connected with the frame 3 . The cutting mechanism includes a power unit, a knife bed 2 and a cutting knife 4 . The power unit is composed of a motor 10, a reduction transmission structure, and an eccentric device. The reduction transmission structure is composed of a final reduction gear 16, a reduction transmission shaft 12, and reduction gears 11, 13. The eccentric device is composed of an eccentric shaft 14 and an eccentric wheel 15. ; The cutting knife 4 is installed in the lower part of the knife bed 2, and the knife bed 2 is connected with the eccentric device through the connecting rod 1, and reciprocates in the guide ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com