Continuous peeling method for walnut kernels

A technology of walnut kernel and epidermis is applied in the field of peeling technology, which can solve the problems of low peeling efficiency, large labor consumption, small output, etc., and achieve the effects of improving labor efficiency, reducing production cost, and reducing production waste water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

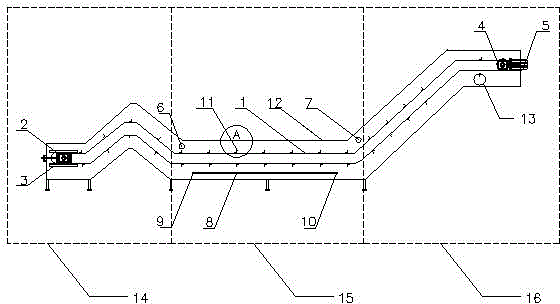

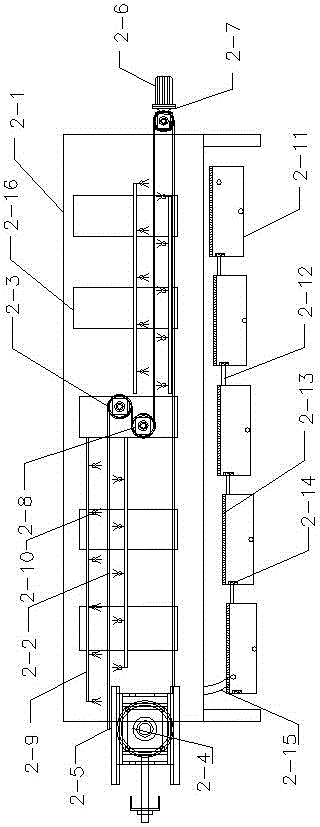

[0018] The equipment needed for the technological process of the method for continuous peeling of walnut kernels of the present invention includes a continuous lye soaking machine, a high-pressure spraying machine, a double-effect cleaning machine, a kernel separator and a countercurrent dryer, wherein the double-effect cleaning machine, peeling What the kernel separator and the counter-current dryer adopted are the double-effect cleaning machine, the skin kernel separator and the counter-current dryer in the prior art.

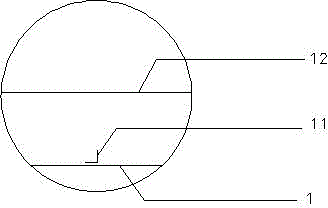

[0019] Such as figure 1 , 2 As shown, the connecting lye soaking machine includes a box body, and the box body is formed by connecting three working boxes, and the three working boxes are respectively a feed sealing box 14 and a soaking and holding box arranged successively from left to right. 15 and the inclined drying box 16, the feed sealing box 14 is connected with the inclined drying box 16 through the soaking holding box 15, and the movable cover plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com