Cotton boll shucker

A technology of peeling machine and cotton, applied in the mechanical field of seed cotton, can solve the problems of low cotton peeling rate, much useless work, great difference in maturity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

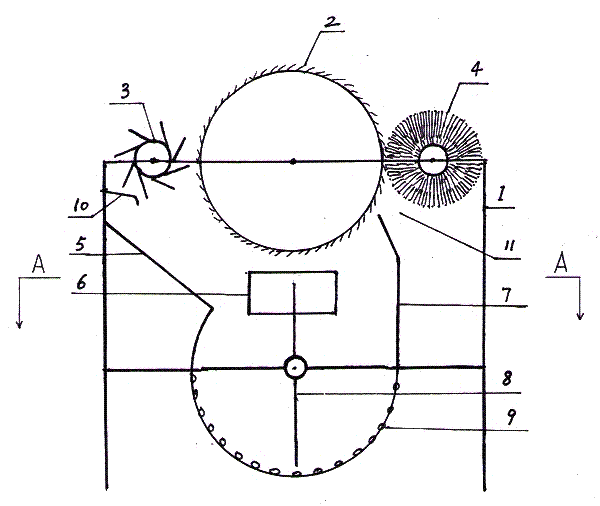

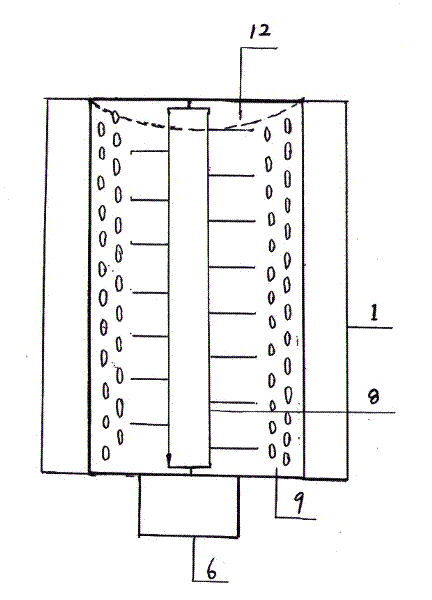

[0021] figure 1 Among them, the feeding port 6 communicates with the shelling chamber 7 in the body 1, and the shelling chamber 7 is provided with a bumping roller 8, and above the bumping roller 8, there is a grabbing roller 2, and the brush roller 4 and the comb roller 3 are located on the picking roller. 2 sides. The lower end or the side of the comb roller 3 has a comb plate 10, and communicates with the shelling chamber 7. There is a cotton board between the brush roller 4 and the cotton roller 2, and the cotton board communicates with the cotton outlet 11. One side of the shelling chamber 7 has a shell outlet, and the shelling chamber 7 bottom has a miscellaneous net 9. The impact roller 8, the catching roller 2, the comb roller 3 and the brush roller 4 are respectively connected with the power system through the transmission device. 5 is the baffle plate.

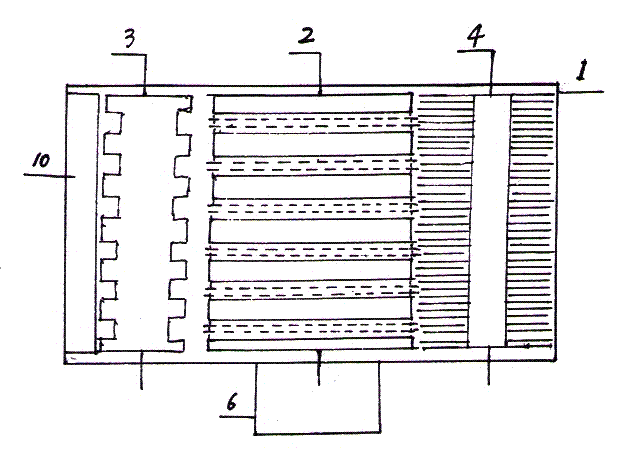

[0022] figure 2 Among them, 1 is the machine body, 2 is the catching roller, 3 is the comb roller, 4 is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com