Novel device for separating copper powder from waste liquid

A technology for separating waste liquid and copper powder, applied in the direction of filtration separation, separation method, mobile filter element filter, etc., can solve the problems that waste liquid cannot continue to be discharged from the electrolytic cell, copper powder is easy to block, and environmental pollution, etc., to achieve Avoid sputtering everywhere, complete separation, and improve separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

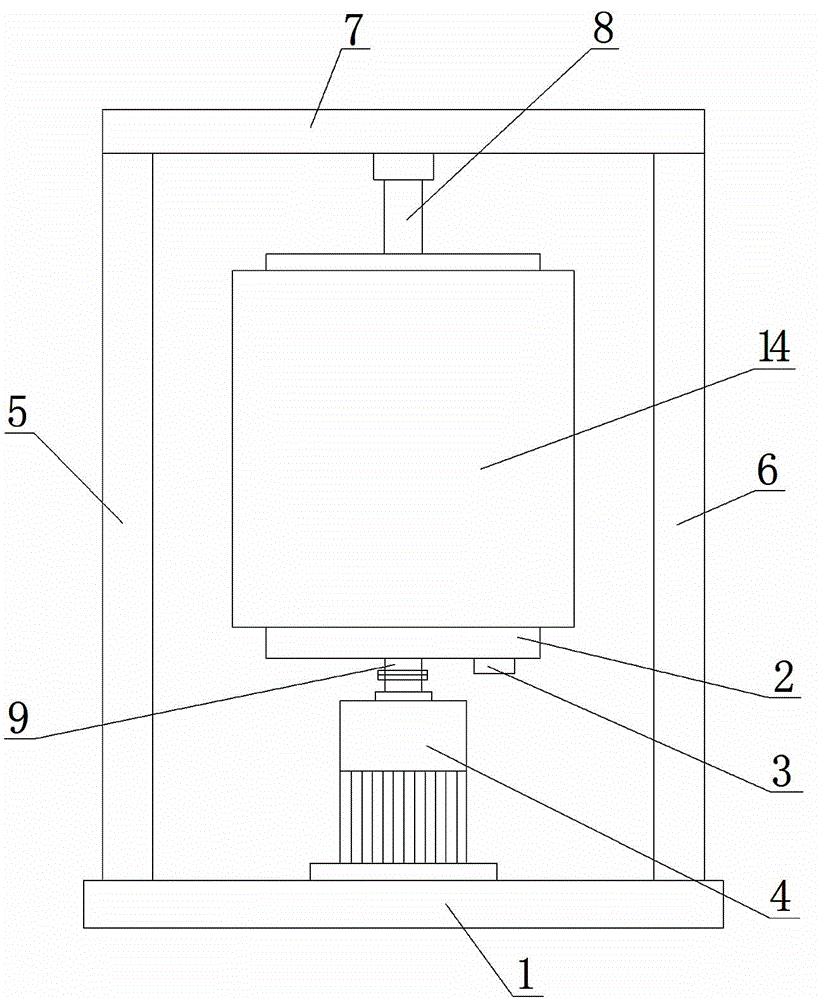

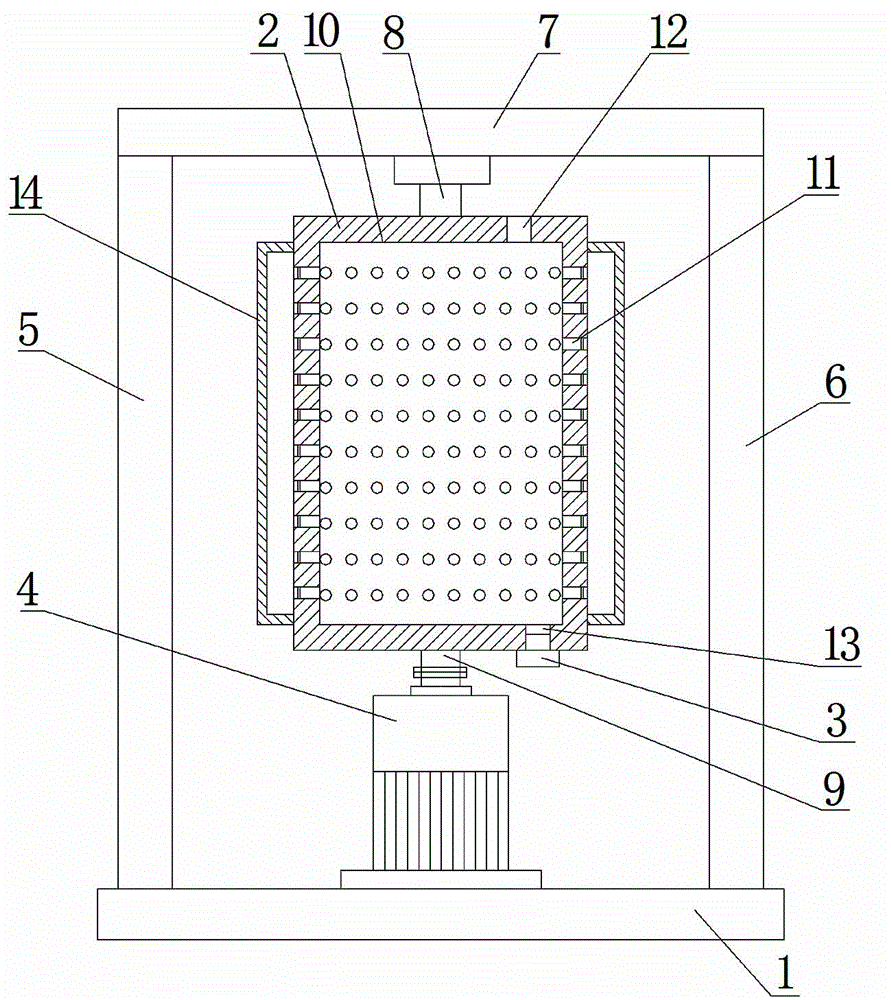

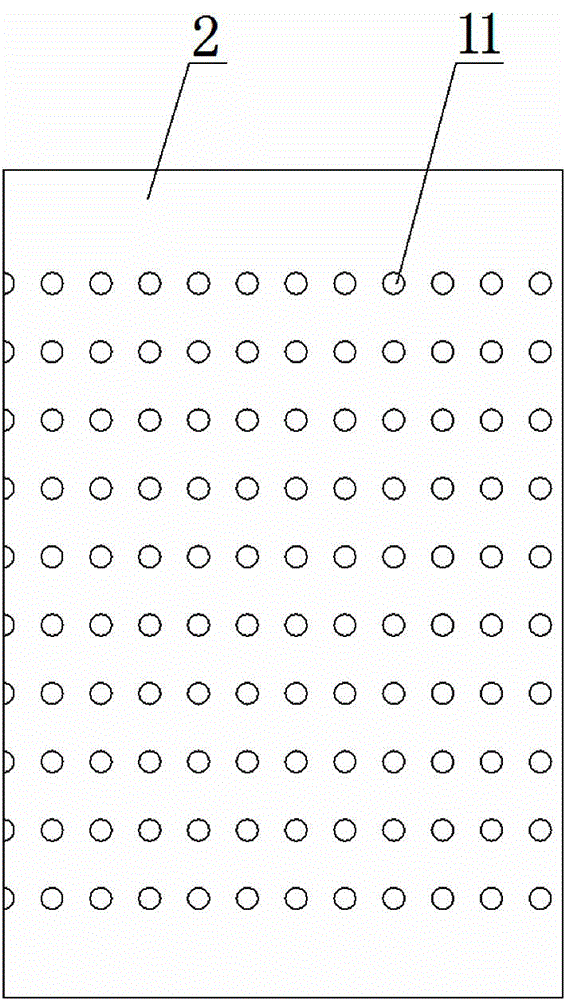

[0012] Such as Figure 1-3 As shown, a new type of device for separating copper powder in waste liquid, it includes a workbench 1, a filter cartridge 2, a motor 4, and a column A5 and a column B6 arranged on the workbench 1, the motor 4 is vertically arranged and It is fixedly installed on the workbench 1, and a beam 7 is arranged between the column A5 and the column B6. Such as Figure 1-3 As shown, the filter cartridge 2 is in a cylindrical shape, and the filter cartridge 2 is arranged between the column A5 and the column B6. The upper and lower ends of the filter cartridge 2 are respectively provided with a rotating shaft I8 and a rotating shaft II9, and the rotating shaft I8 is rotatably mounted on the beam 7 , the rotating shaft II9 is connected to the output end of the motor 4, the middle p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com