Cotton seed, commodity linter and grease raw material co-production process based on delinting technology of cylindrical brushing machine

A cotton seed and brushing machine technology, which is applied in the direction of oil/fat production, seed and root treatment, fat production, etc., can solve the problem of unreasonable utilization of resources, and achieve guaranteed seed quality, high grade, and high oil yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

[0011] The present invention designs the technological process according to the cotton product processing standard and the seed processing technical standard, and this technological method is very clear to the technical personnel in this profession.

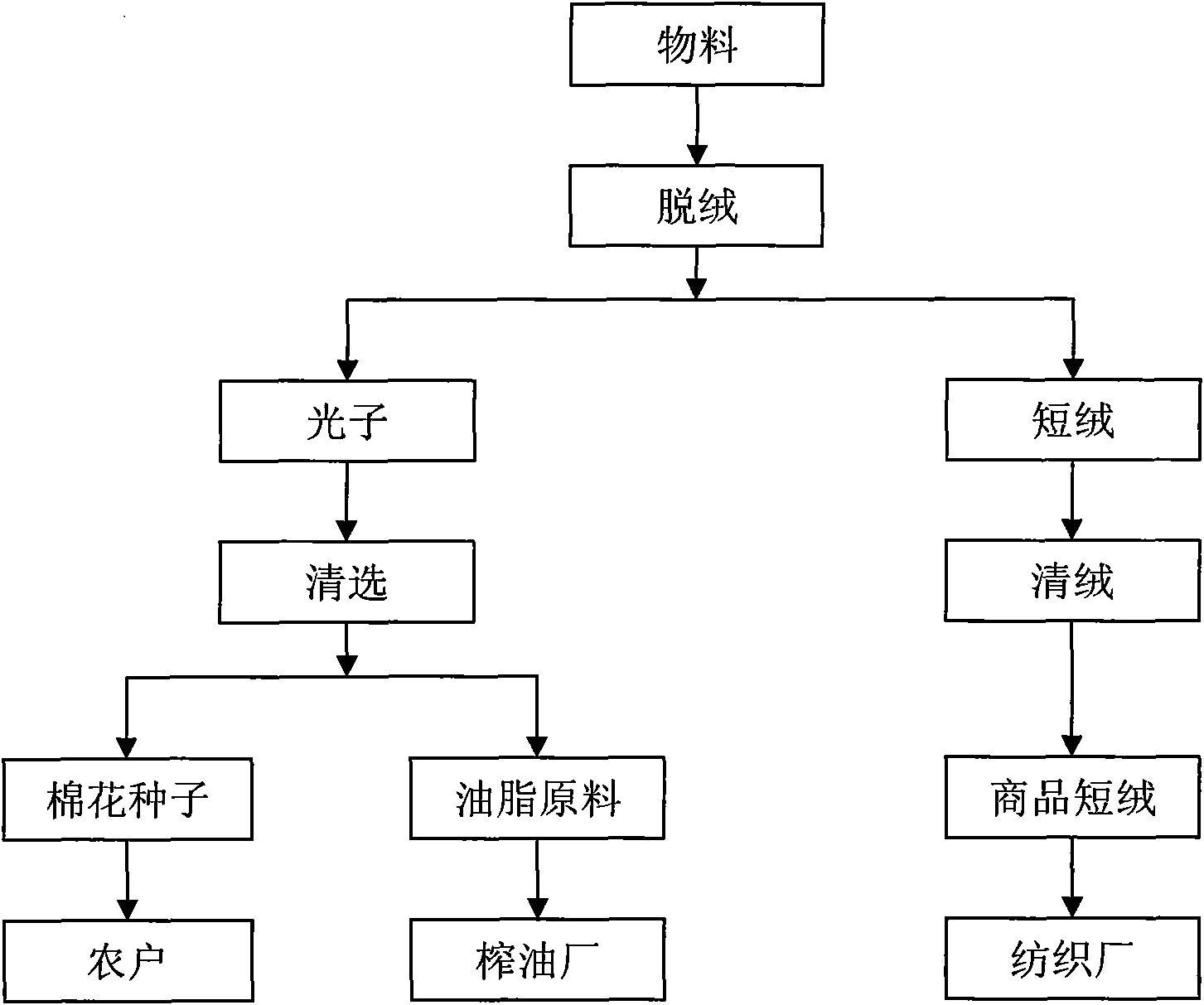

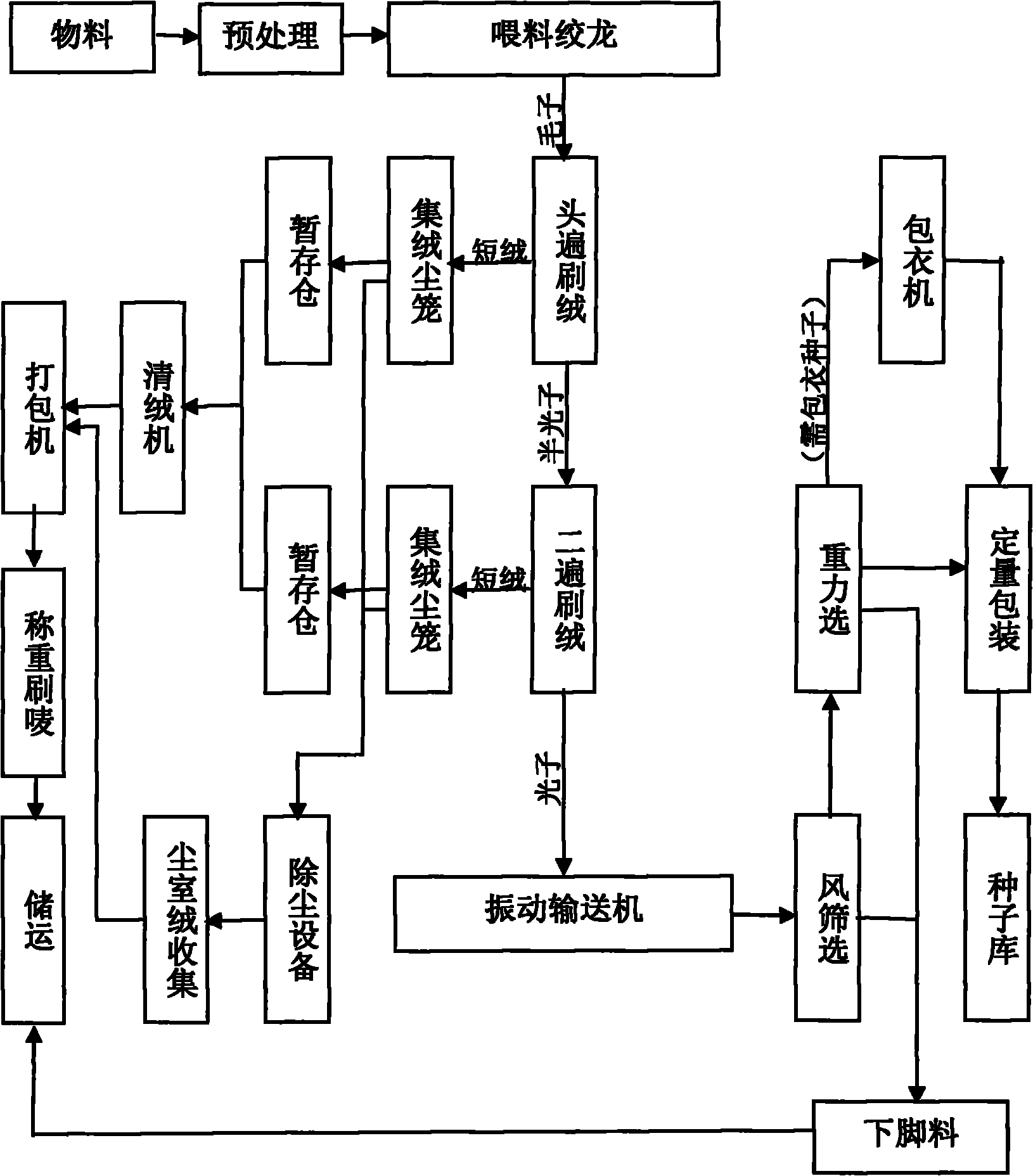

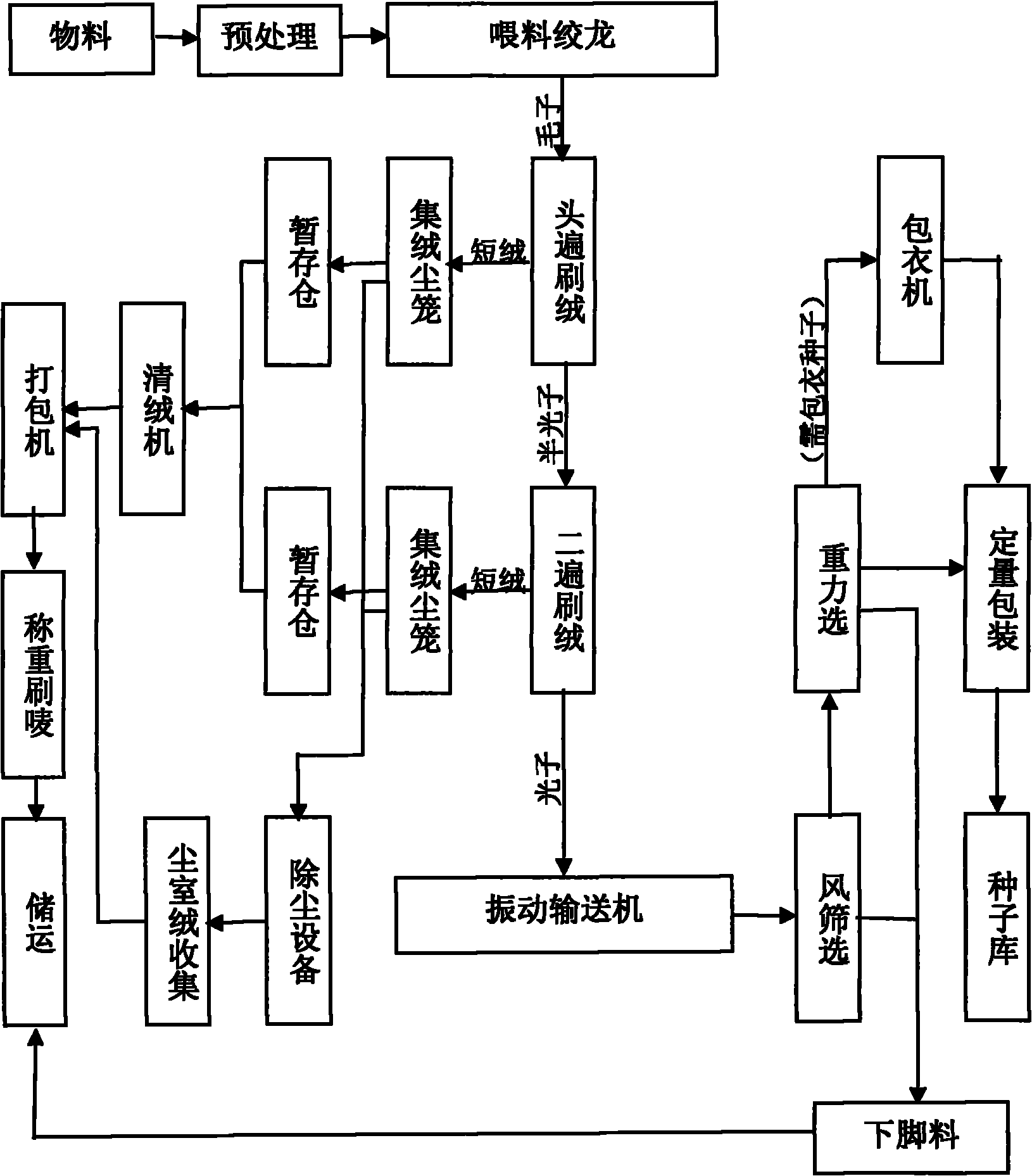

[0012] The material (hair) is processed to simultaneously generate cotton seeds, commercial linter, and oil raw materials; the specific process steps are: pre-treatment of the material (hair), the hair enters the dehairing link through the feeding system, and is brushed by the cylinder. After the machine is brushed twice, it is separated into two components: short pile and photon. The short pile is collected and temporarily stored after being brushed first and twice, and then weighed and marked as commercial short pile after being cleaned and packed. ; The photons are sent to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com