Controllable flux permanent magnetic synchronous motor of multiple pole number built-in mixed rotor magnetic path structure

A hybrid and rotor technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc., can solve the problems of inverter power device damage, loss of magnetic field weakening control ability, decline, etc., and achieve remarkable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

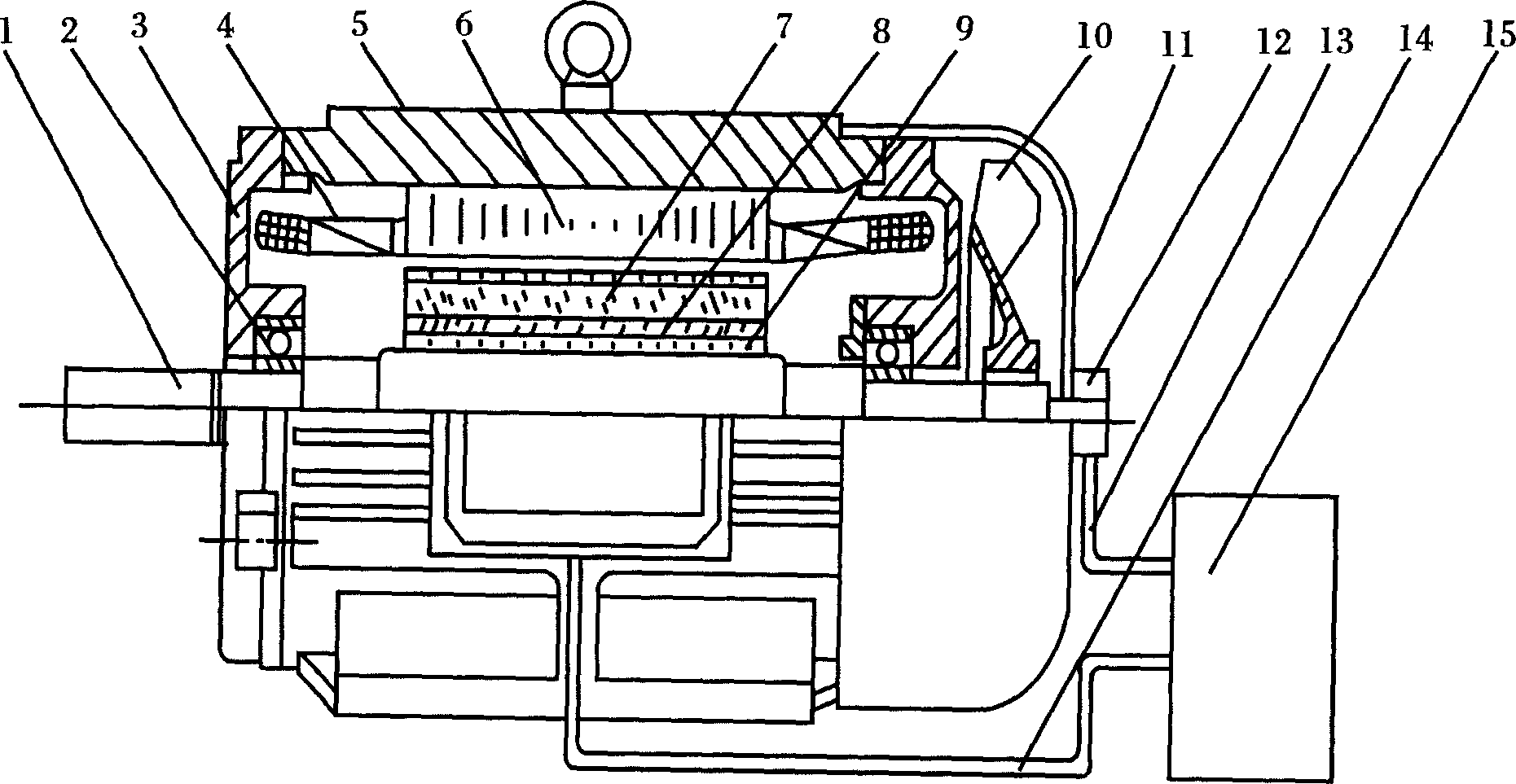

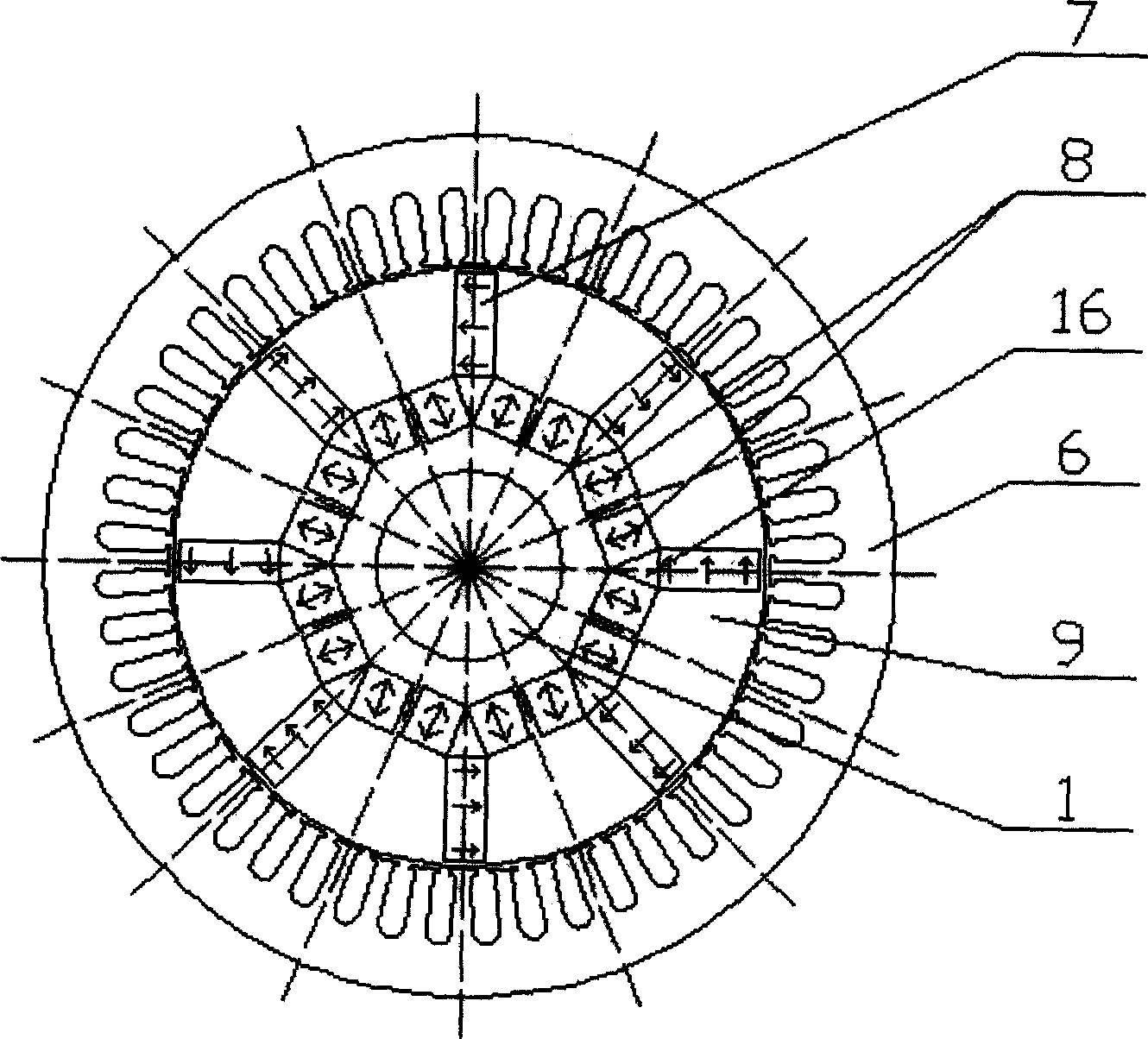

[0010] Specific embodiments of the present invention are described below in conjunction with accompanying drawings, and the whole motor is implemented as follows.

[0011] It has been mentioned above that the multi-pole built-in hybrid rotor magnetic circuit structure controllable flux permanent magnet synchronous motor of the present invention - memory motor, except for the motor rotor, other parts of the motor are basically the same as the traditional permanent magnet synchronous motor. That is to say, the end cover 3 of the motor, the frame 5, the air-conditioning fan 10, the windshield 11, the stator core 6, the winding, insulation, embedding, dipping, drying, and pressing into the frame 5 of the three-phase stator winding 4 The manufacturing process is basically the same as that of the traditional permanent magnet synchronous motor. What needs to be emphasized again is that ① in order to weaken the reluctance torque of the permanent magnet motor, the stator core 6 is made...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com