Variable flux permanent magnet synchronous motor

A permanent magnet synchronous motor technology, applied in the field of motors, can solve the problems of weakening a very small part of permanent magnet flux, reducing efficiency, and difficulty in adjusting magnetism, so as to achieve the effects of reducing armature loss, improving motor efficiency, and easily adjusting magnetism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

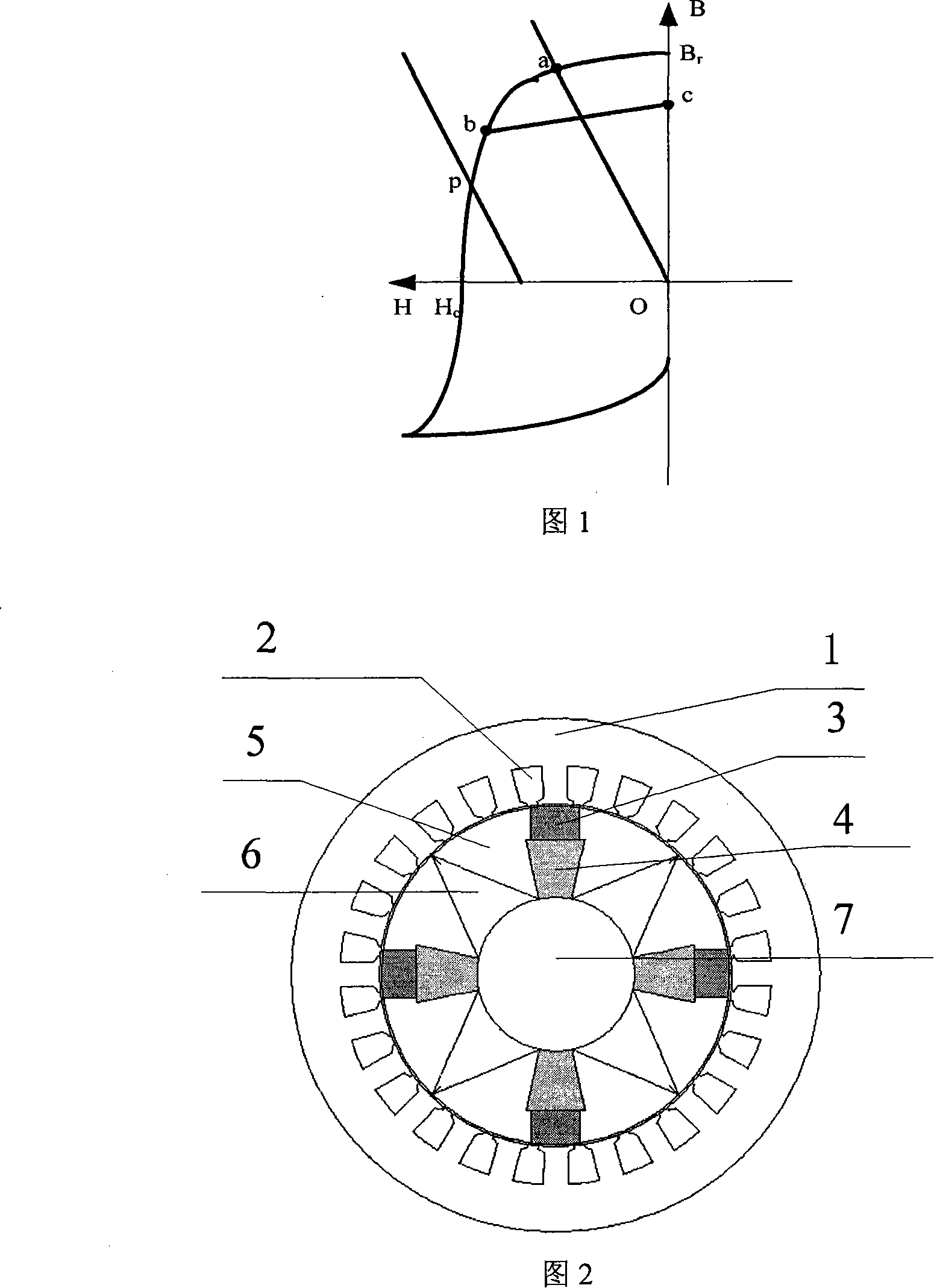

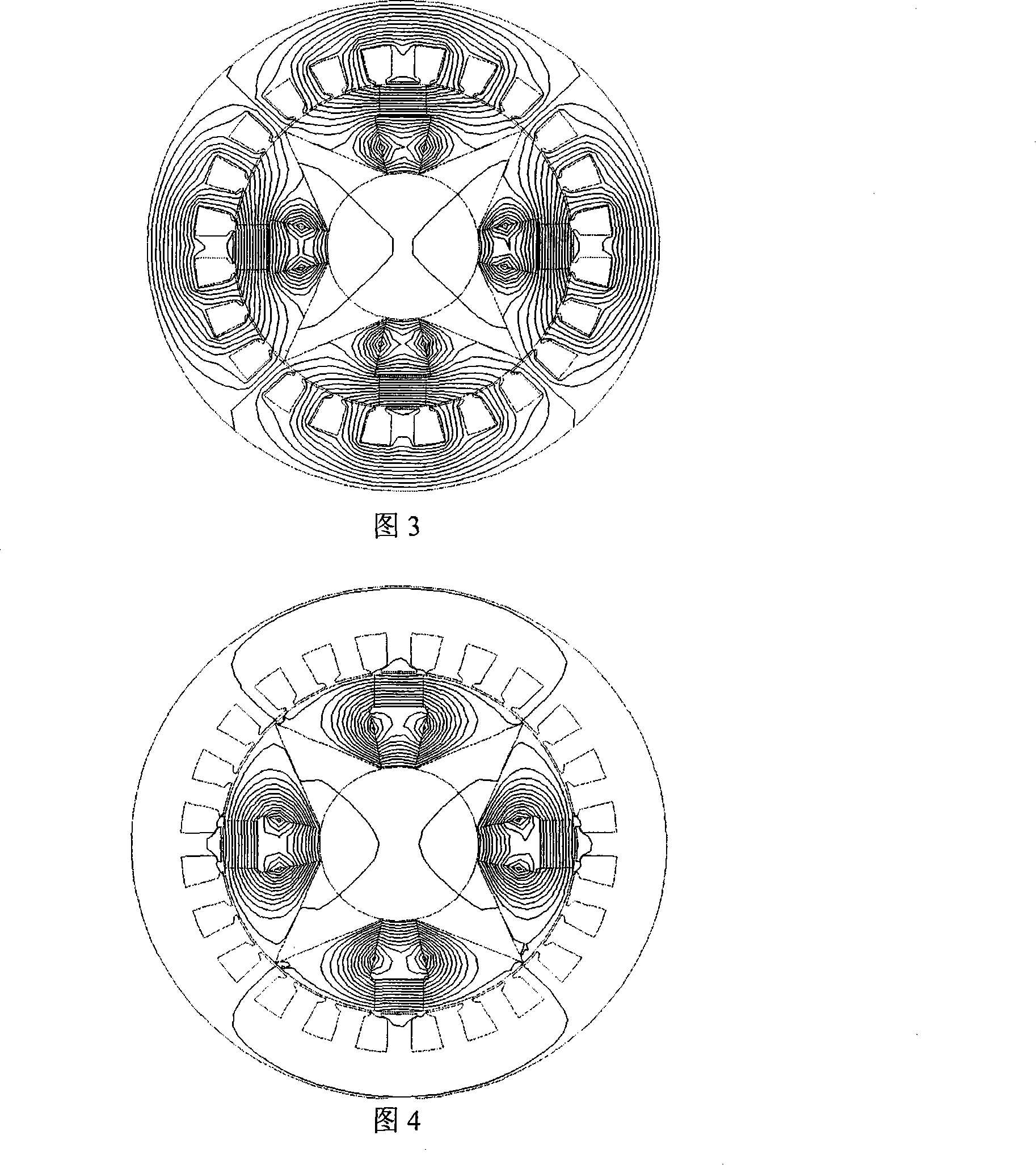

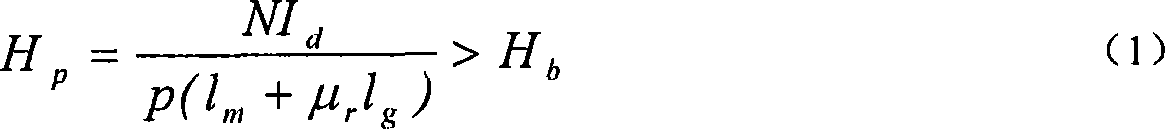

[0015] The variable flux permanent magnet synchronous motor adopts the stator direct axis pulse current i before the motor runs d The AlNiCo permanent magnet is saturated and magnetized, and the magnetization direction is the same as that of the NdFeB magnet saturated and magnetized before installation. Use i when the motor is running below base speed d =0 control mode, in order to ensure that the permanent magnet magnetic properties remain unchanged when the motor is running below the base speed, the alnico permanent magnet needs to be stabilized. Figure 1 shows the hysteresis loops of AlNiCo magnets in the second and third quadrants. Point a is assumed to be the operating point of the AlNiCo permanent magnet after saturation magnetization, and point b is assumed to be the return line of the permanent magnet after the magnetization is stabilized. starting point. Obviously, when the working point of the alnico magnet moves on the return line bc, the demagnetization of the pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com