Device for calibrating high-speed motion measuring instrument

A calibration device and high-speed motion technology, which is applied in the testing/calibration of measuring devices, speed/acceleration/shock measurement equipment, speed/acceleration/shock measurement, etc., can solve the problem of slow motion speed, lack of calibration device to reproduce dynamic quantity, The measurement equipment cannot be calibrated and other problems, to achieve the effect of effective calibration measurement, reasonable overall structure design, and accurate calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

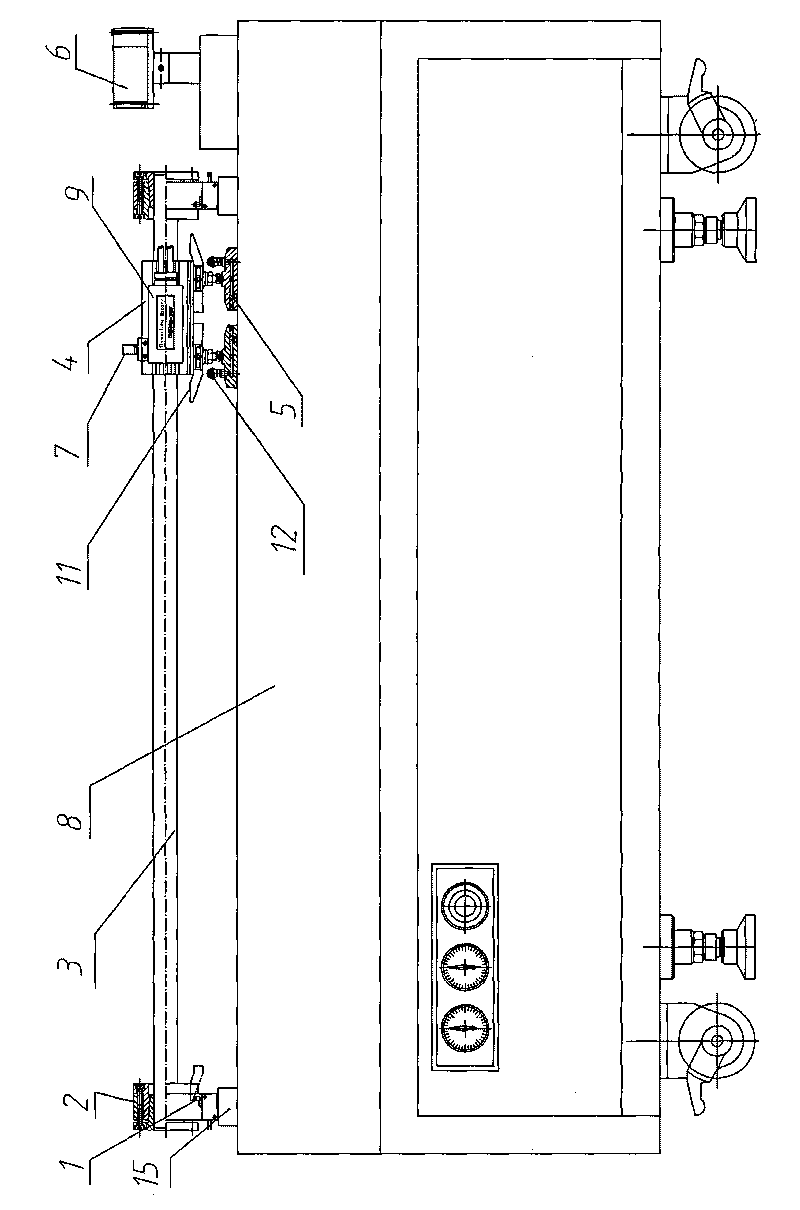

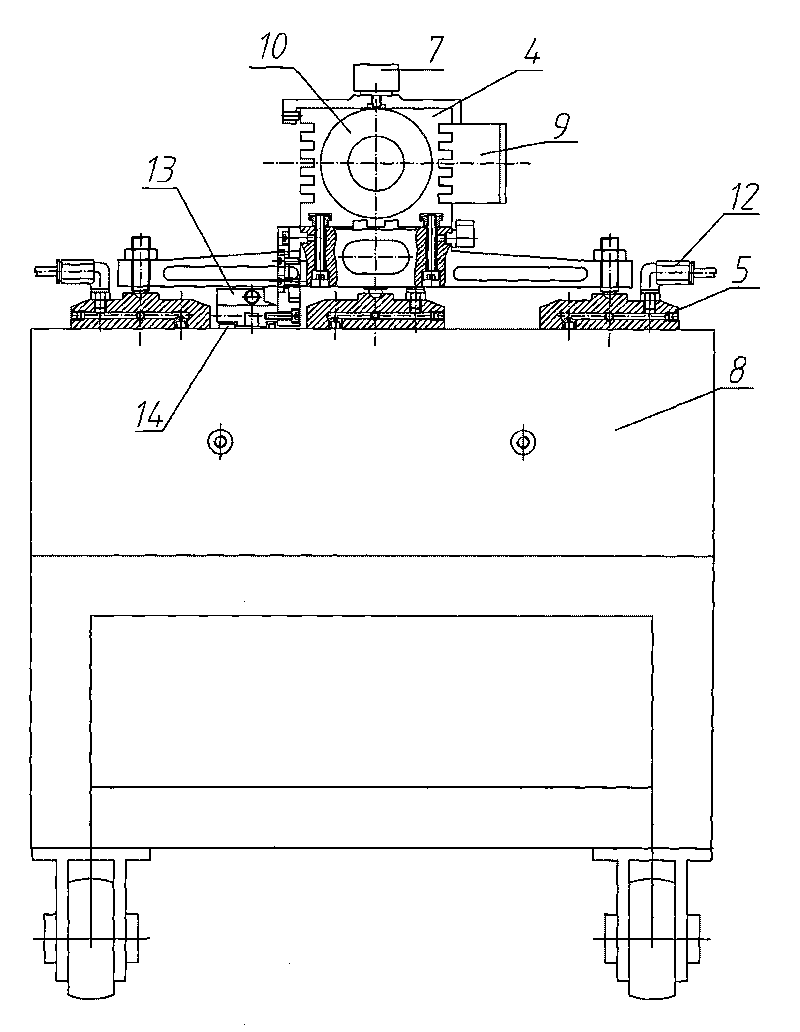

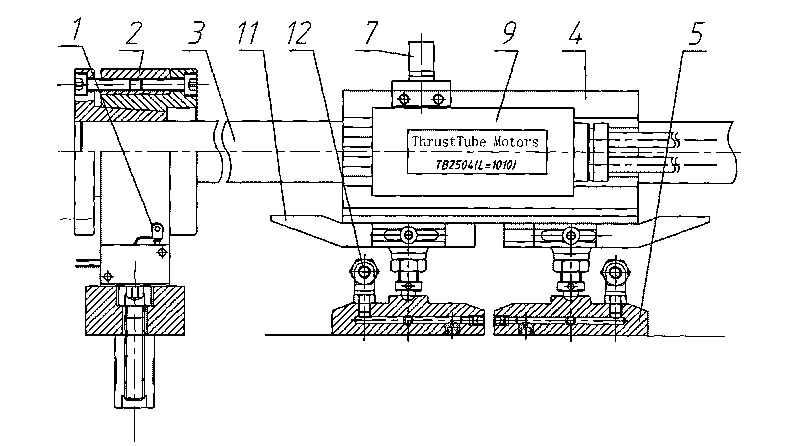

[0020] Such as Figure 1 to Figure 3 As shown, a high-speed motion measuring instrument calibration device includes a workbench 8 whose upper surface is a smooth horizontal plane. A support 15 is respectively arranged on both sides of the upper surface of the workbench 8, and a permanent magnetic steel thrust is horizontally arranged between the two supports 15. Bar 3, the permanent magnetic steel thrust bar 3 is fitted with a linear motor mover 4 in a magnetic levitation manner, and the lower end of the linear motor mover 4 is provided with an air bearing 5 and the upper surface of the workbench 8 to form a non-contact support; It also includes a steel strip grating measurement system, wherein the steel strip grating reading head 13 is installed downward on the side of the lower end face of the linear motor mover 4, and the steel str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com