Assembled scheme for brushless DC motor slot number and magnetic steel number

A technology of brushed DC motor and number of slots, which is applied in the direction of electrical components, electromechanical devices, magnetic circuit static parts, etc., can solve the problems of low-speed pulsation difficult to eradicate, radial component force, affecting bearing life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

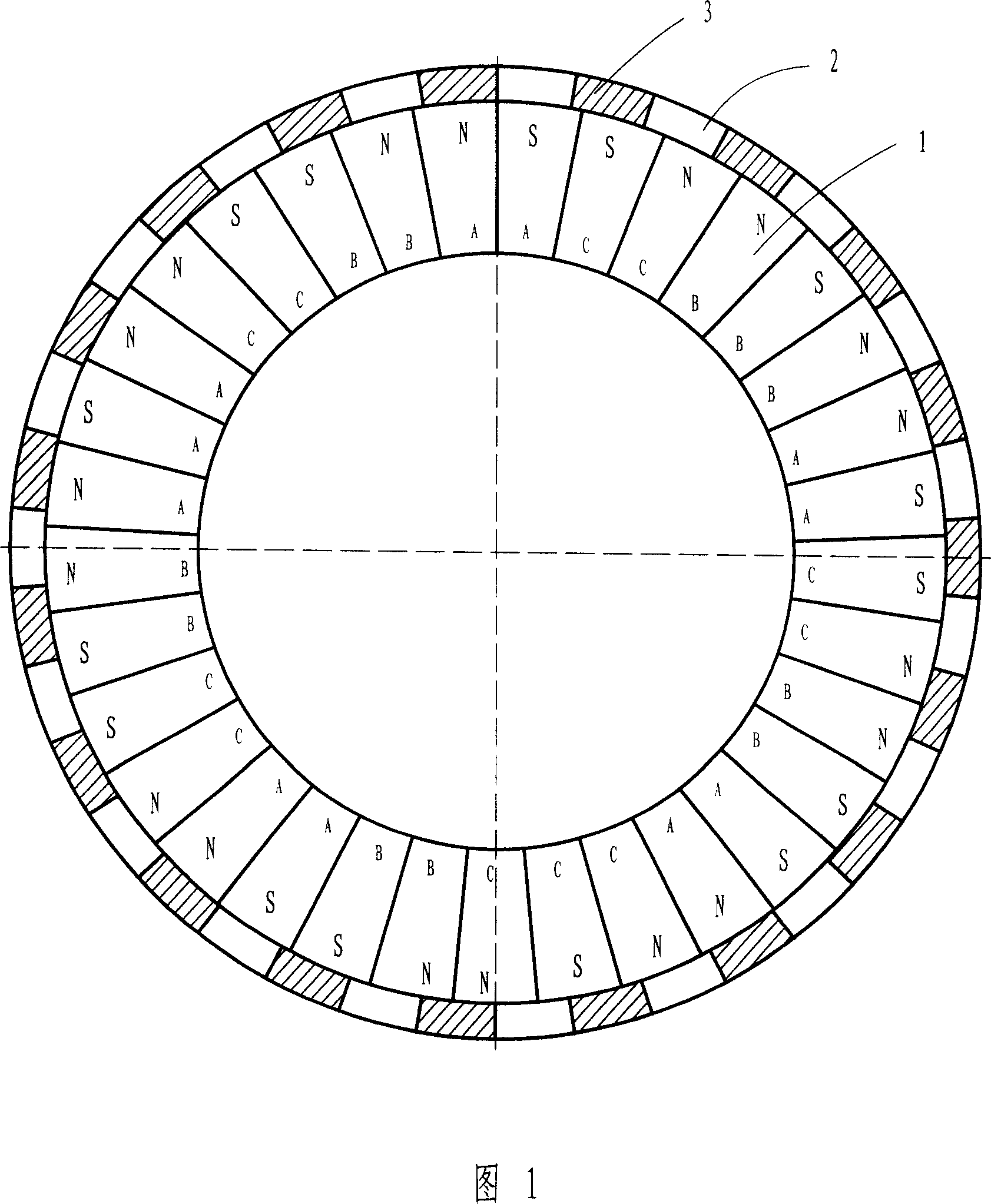

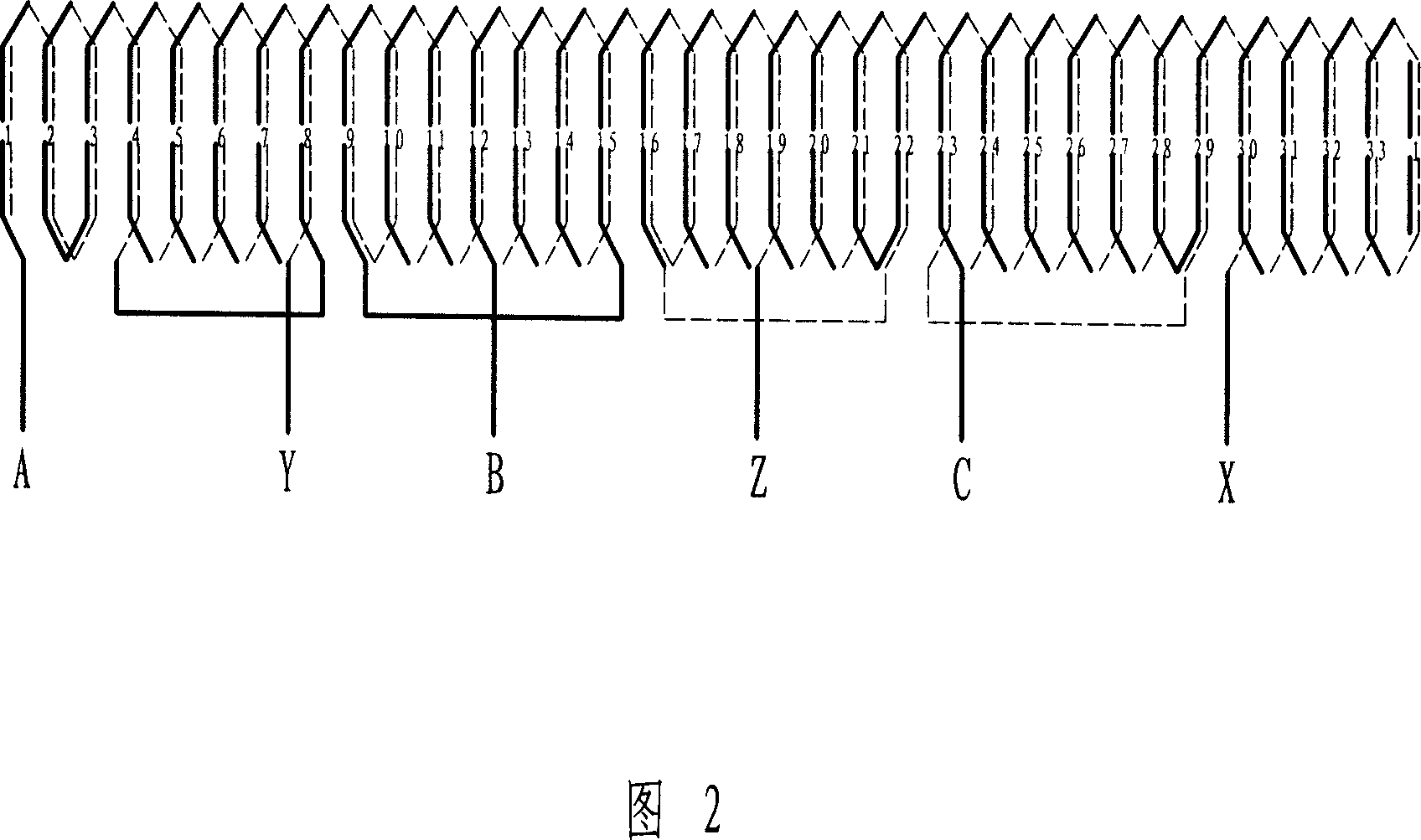

[0027] Example: Three-phase 33-slot 38-pole outer rotor brushless DC motor

[0028] Taking a three-phase motor as an example, according to the above principles, a motor structure with 33 slots in the stator and 38 poles in the rotor is selected. Figure 1 is a schematic diagram of the arrangement of the stator and rotor poles of the motor: the inside A, B, and C of the stator pole 1 indicate the phase sequence, and the outside N and S indicate the polarity of the pole. As shown in FIG. 1 , the N pole magnet 2 and the S pole magnet 3 of the rotor are bonded in the steel ring of the outer rotor. According to the arrangement diagram of stator polarity and phase sequence, the wiring diagram can be drawn. Figure 2 is the wiring diagram of the motor. For clear expression, the wiring diagram of phase A is also drawn specifically.

[0029] The phase sequence arrangement of the stator poles must not only meet the order of A, B, and C, but also meet the symmetry requirements of each pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com