Manufacture process and application technical process of energy-saving and emission-reducing high-gradient magnetic separating machine with ultrastrong magnetic field

A high-gradient magnetic separation, energy-saving and emission-reducing technology, which is applied in high-gradient magnetic separators, magnetic/electric field water/sewage treatment, etc., can solve the problem of difficult cleaning of ore-discharging magnetic bonding, large consumption of production materials, and mechanical inclusions And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Anshan-depleted magnetite ore, using wet magnetic separation process, the ore is mainly magnetite, containing a small amount of hematite, the gangue minerals are mainly quartz, containing a small amount of hornblende, margin stone, calcite, mica, green curtain Stone and apatite, the ore is in a banded structure, composed of interlayers of iron mineral layers and gangue layers. The average thickness of iron ore strips is 0.5-0.8 mm, and the average thickness of non-iron ore strips is 0.2-0.4 mm. The iron minerals are fine-grained inlaid cloth, the inlaid cloth particle size is about 0.1 mm, the ore specific gravity is 3.3-3.5, the ore Platinum degree is 8-12, and the magnetic rate is about 33-36%.

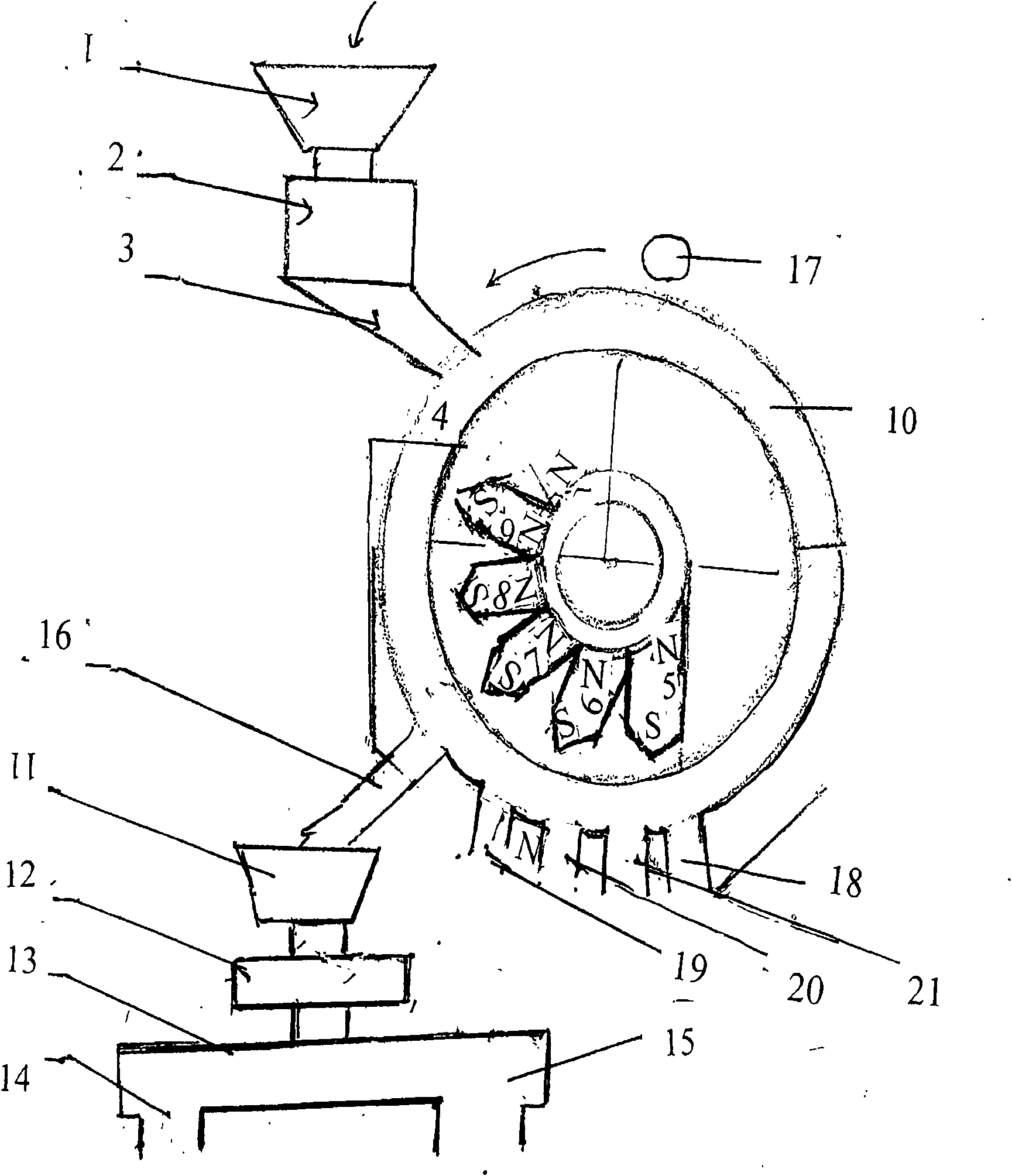

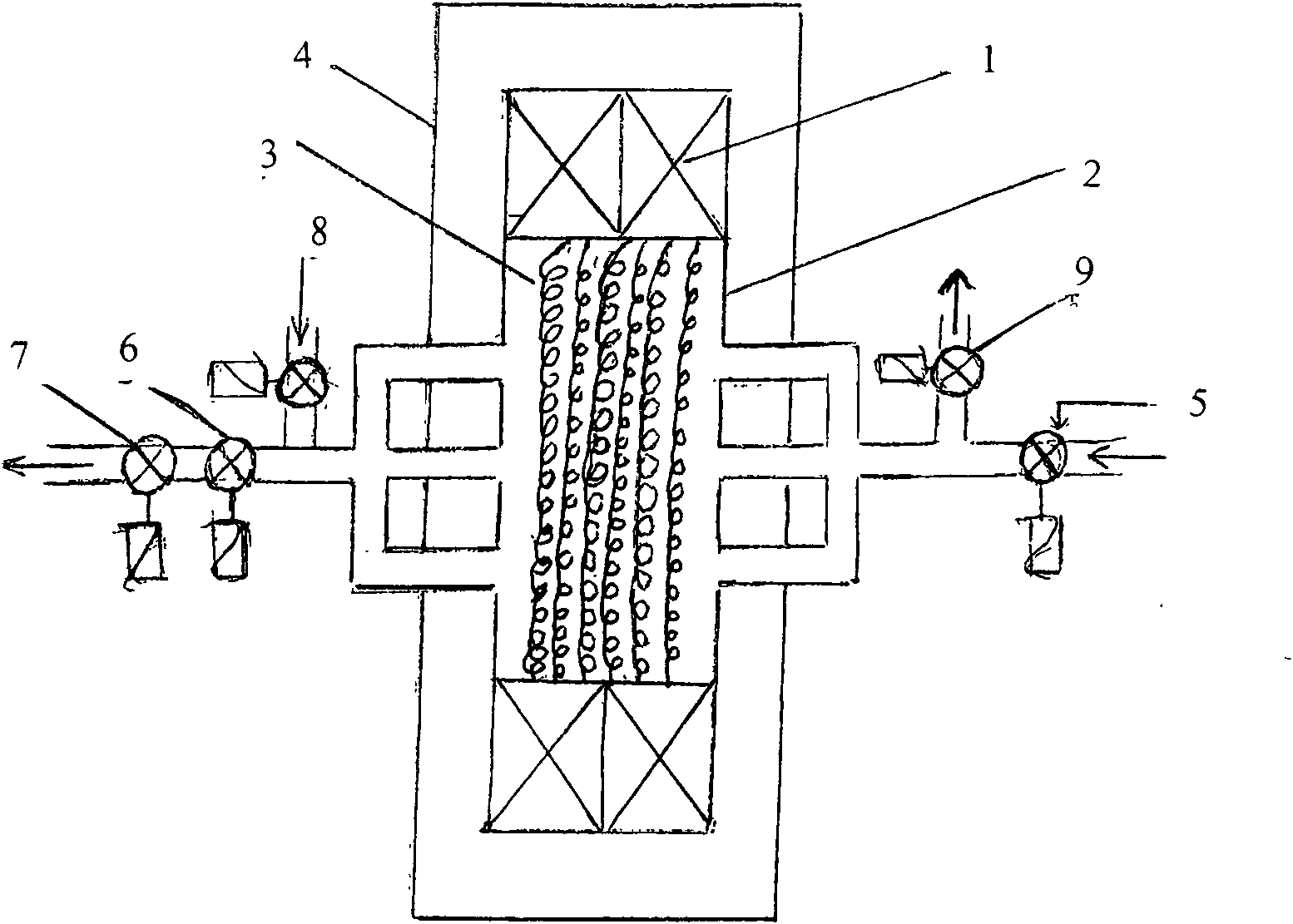

[0067] Raw ore is ball milled after coarse crushing and intermediate crushing. After sieving, it is graded - 200 mesh 75%, and enters this high-gradient magnetic separation and separation. Magnetically separate the magnetic concentrate into the press Figure 4 The process f...

Embodiment 2

[0069] Raw material composition is with embodiment 1, and its preparation technology is with embodiment 1.

[0070] Described rare earth permanent magnet material: adopt high-performance Nd-Fe-B series permanent magnet, kind is: N50M, N52, ferrite adopts anisotropic strontium ferrite: maximum magnetic energy product (BH) m=26KJ / m 3 , coercive force Hc=260KA / m, intrinsic coercive force is 275KA / m, anisotropic alnico permanent magnet, maximum energy product (BH)m=44KJ / m 3 , coercive force 50KA / m, other preparation technology and application are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Maximum energy product | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com