Controllable flux permament magnetic synchronous motor of built-in mixed rotor magnetic path structure

A permanent magnet synchronous motor and hybrid technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc., can solve the problems of inverter power device damage, loss of magnetic field weakening control ability, decline, etc., to achieve the best results significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

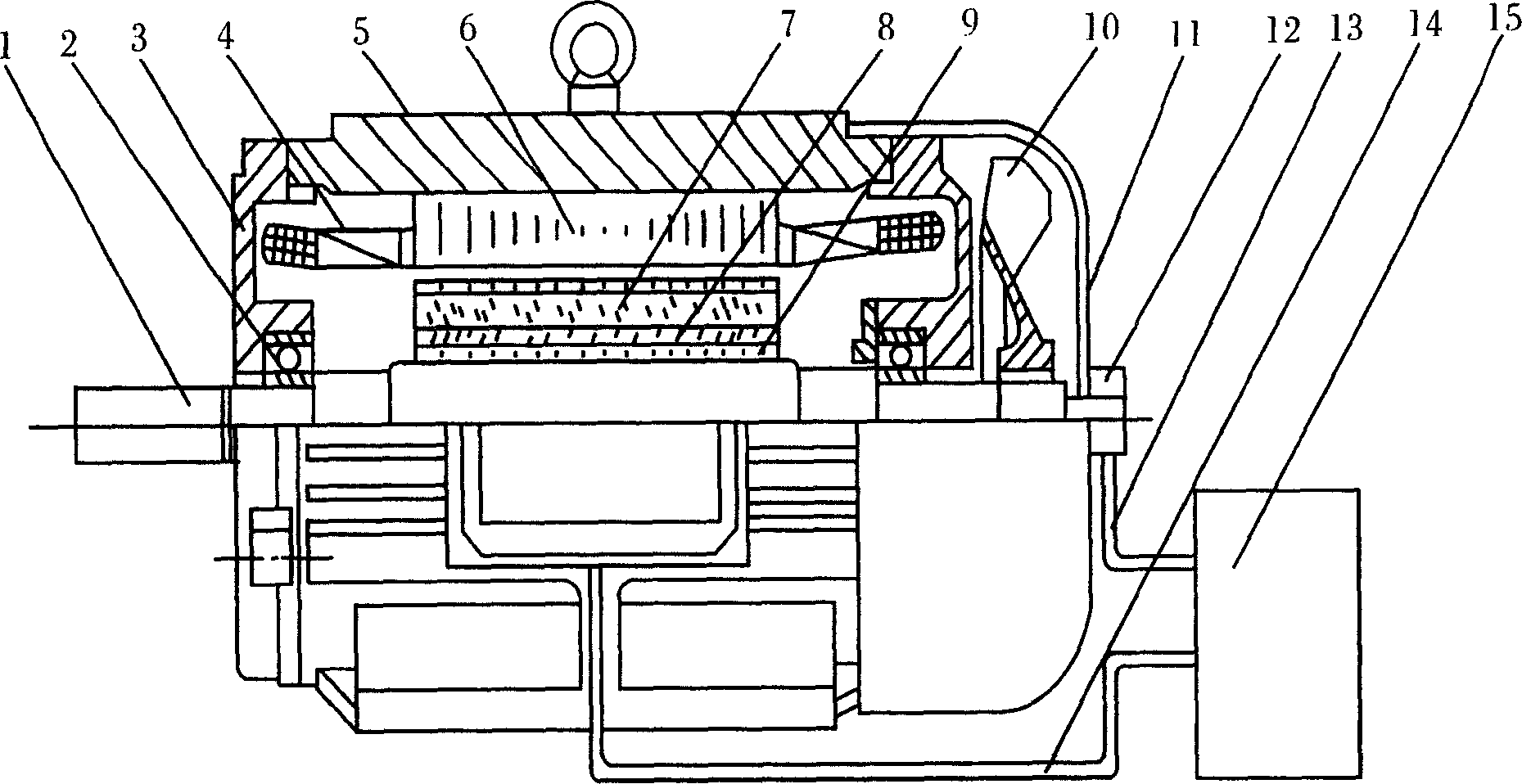

[0011] The specific embodiments of the present invention will be described below with reference to the accompanying drawings:

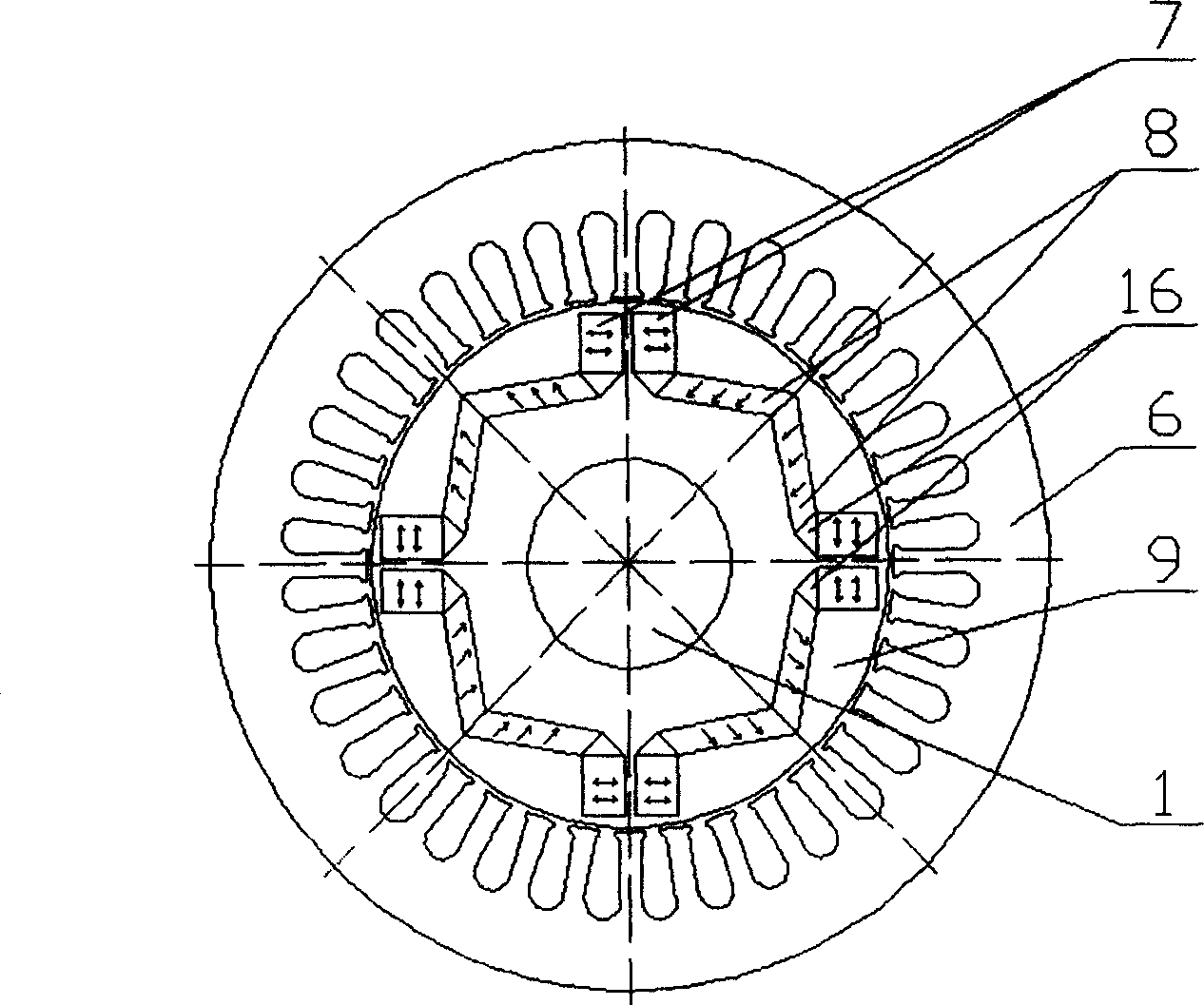

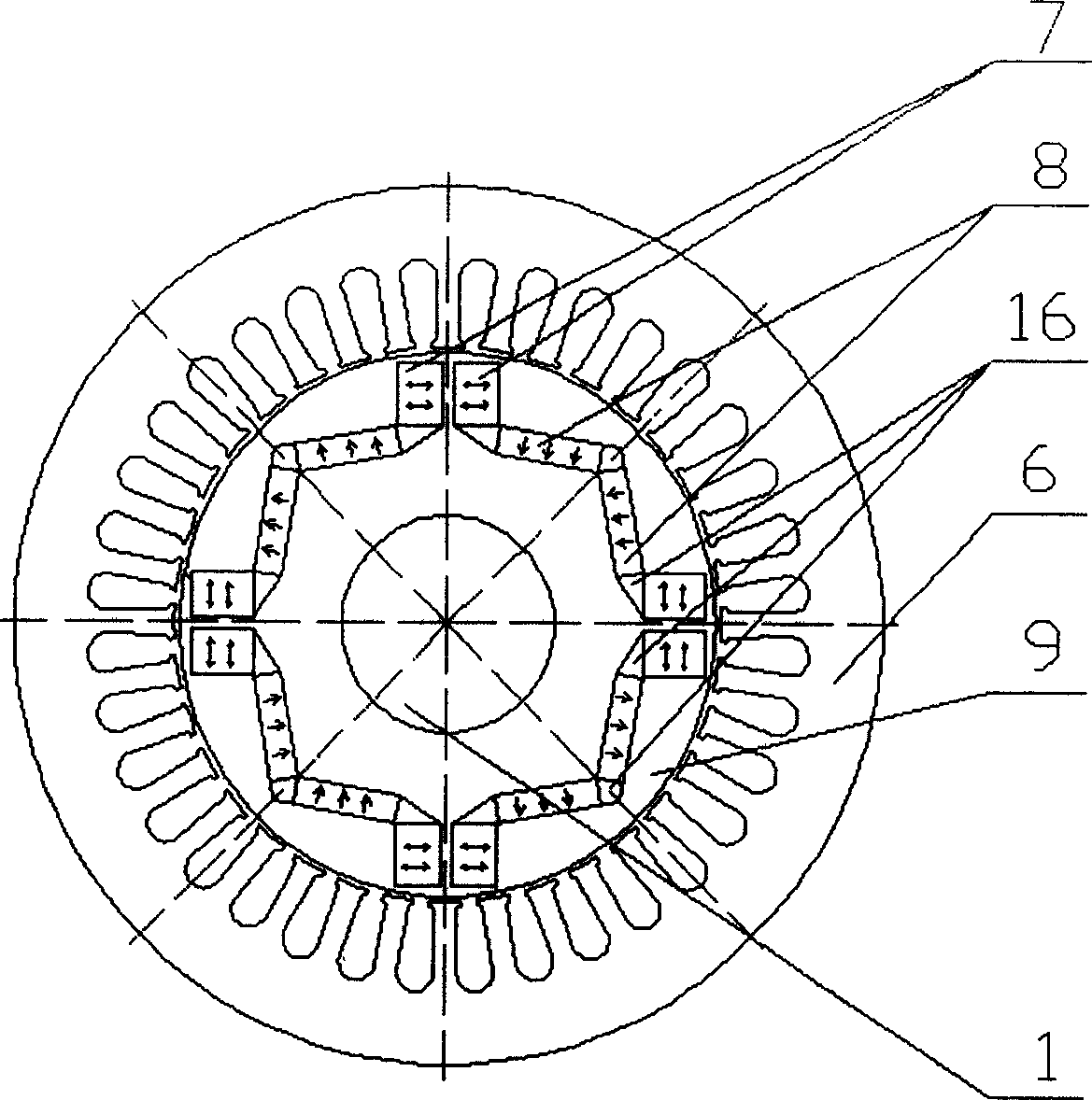

[0012] figure 2 versus image 3 The difference between the two is that the shape of the neodymium iron boron permanent magnets 8 placed radially and their magnetizing directions are different, and the other aspects are completely the same. The specific implementation is also exactly the same. The whole motor is implemented according to the following instructions.

[0013] As mentioned above, the magnetic flux controllable magnetic flux permanent magnet synchronous motor with a built-in hybrid rotor magnetic circuit structure of the present invention is a memory motor. Except for the motor rotor, other parts of the motor are basically the same as the traditional permanent magnet synchronous motor. In other words, the motor end cover 3, frame 5, air-conditioning fan 10, wind cover 11, stator core 6, three-phase stator winding 4 winding, insulation, wire e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com