A method for obtaining high magnetic sintered NdFeB by hot isostatic pressing

A technology of hot isostatic pressing and hot isostatic pressing diffusion, which is applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problems of magnet sample thickness limitation and immature grain boundary diffusion process, etc. Uniform grain boundary phase distribution and low melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

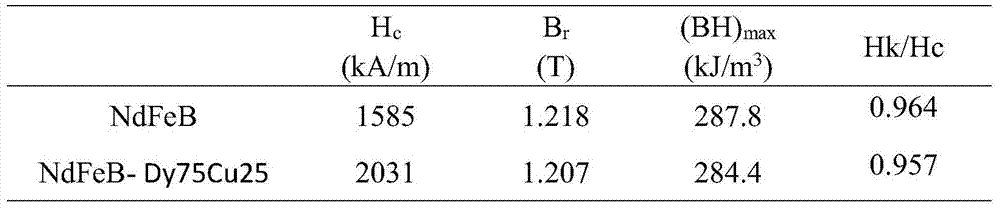

Embodiment 1

[0022] The upper and lower surfaces of 8mm thick 38H NdFeB magnets are covered with 0.5mm thick Dy75Cu25 alloy sheets;

[0023] Step 1: Select 38H commercial NdFeB magnets and process them into 30mm×30mm×8mm samples. The Dy75Cu25 alloy was smelted in vacuum, and cut into thin slices with a thickness of 0.5 mm. The cut thin slices were polished with sandpaper to remove the oxide skin, and placed in acetone to ultrasonically clean;

[0024] Step 2: Place a Dy75Cu25 alloy sheet on the upper and lower surfaces of the NdFeB magnet, and place the alloy sheet and the magnet in a graphite crucible;

[0025] Step 3: Put the graphite crucible prepared in step 2 in a hot isostatic pressing machine, and perform hot isostatic pressing diffusion heat treatment and annealing heat treatment. 5h, slow cooling;

[0026] Step 4: Put the prepared NdFeB magnet into the VSM to measure the magnetic properties. The results are shown in Table 1. It can be seen that the Dy / Cu diffusion effect of the...

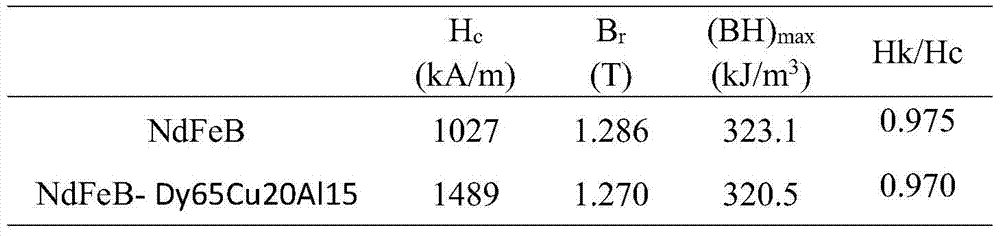

Embodiment 2

[0030] The upper and lower surfaces of the 1cm thick N40 NdFeB magnet are covered with 0.8mm thick Dy65Cu20Al15 alloy sheets;

[0031] Step 1: Select N40 commercial NdFeB magnets and process them into 40mm×20mm×10mm samples. The Dy65Cu20Al15 alloy was smelted in vacuum, and cut into thin slices with a thickness of 0.8 mm. The cut thin slices were polished with sandpaper to remove the oxide scale, and placed in acetone to ultrasonically clean;

[0032] Step 2: Place a Dy65Cu20Al15 alloy sheet on the upper and lower surfaces of the NdFeB magnet, and place the alloy sheet and the magnet in a graphite crucible;

[0033] Step 3: Put the graphite crucible prepared in step 2 in a hot isostatic pressing machine, and perform hot isostatic pressing diffusion heat treatment and annealing heat treatment. The applied pressure is 80 MPa, the diffusion temperature is 900 ° C, the temperature is kept for 5 hours, and then annealed at 550 ° C. 6.5h, slow cooling;

[0034] Step 4: Put the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com