Vortex auxiliary system and method for preparing fiber reinforced composite material by chemical vapor infiltration method

A chemical vapor infiltration and composite material technology, applied in the field of eddy current auxiliary system and preparation, can solve the problems of increasing sample thickness, destroying the integrity of mechanical properties, and unable to deposit cylindrical samples with higher thickness, so as to achieve increased compactness and uniform density properties, increased gas diffusion kinetic energy, and increased material density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

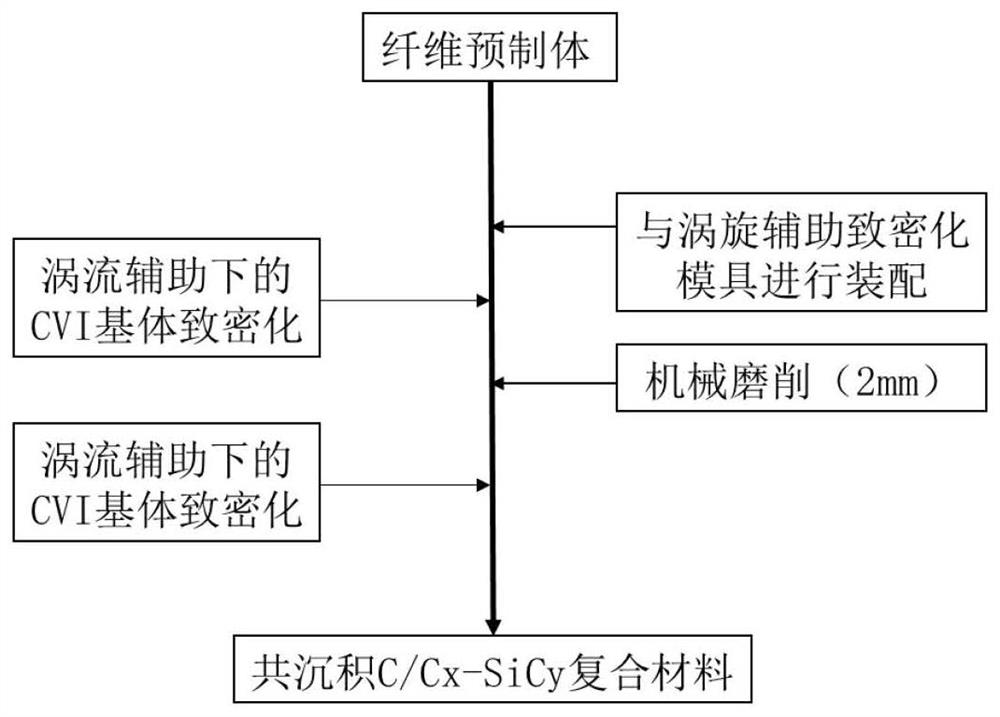

[0068] Example 1. Eddy-current-assisted CVI co-deposition of carbon-rich C / Cx-SiCy composites for densification.

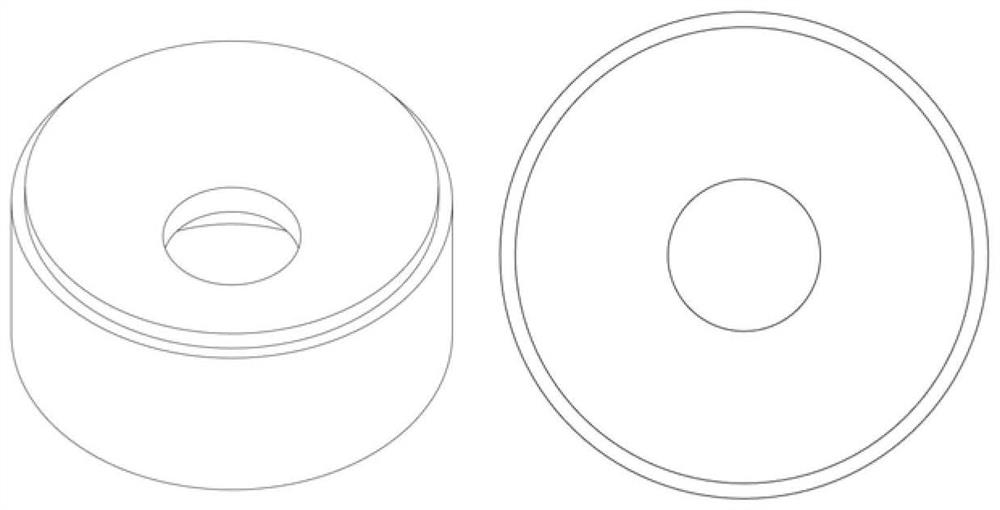

[0069] Step 1: Prepare a 2.5D needle-punched carbon felt (density 0.41g / cm3) preform into a hollow cylinder with an outer diameter of 42mm, an inner diameter of 18mm, and a height of 70mm.

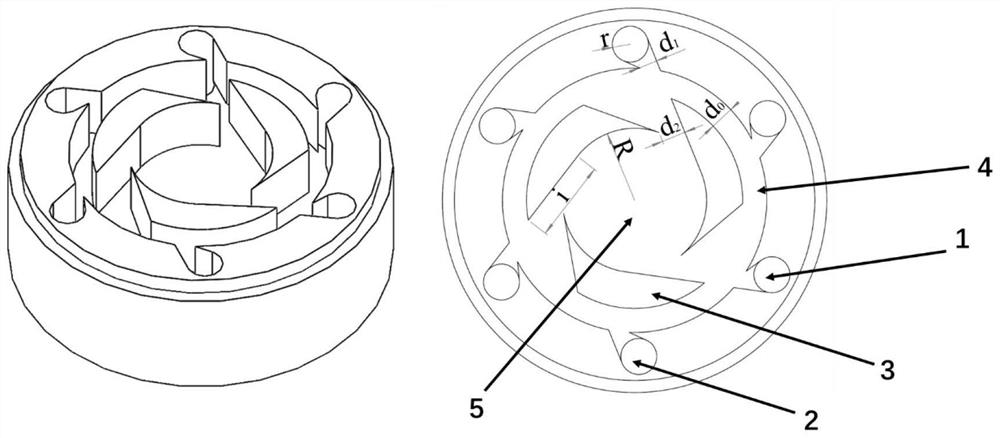

[0070] Step 2: Assemble the mold according to the order of gas inlet, auxiliary vortex platform, deposition chamber, and gas outlet, put the preform into it, and place it in a high-temperature vacuum furnace. Deposit the preform according to the following process parameters: deposition temperature 1100°C, atmospheric pressure 5000Pa, methane: 20ml / min, hydrogen 200ml / min, carrier gas hydrogen 16ml / min, argon 600ml / min, the molar mass ratio of hydrogen to MTS is 10:1. Deposit for 50h, then cool down naturally, repeat 2 times. The preform was removed from the graphite mold to obtain 0.58 g / cm 3 C / Cx-SiCy composites.

[0071] Step 3: Grind the outer surface of the composite ...

Embodiment 2

[0075] Example 2. Eddy-current-assisted CVI co-deposition of silicon-rich C / Cx-SiCy composites for densification.

[0076] Step 1: Prepare a 2.5D needle-punched carbon felt (density 0.41g / cm3) preform into a hollow cylinder with an outer diameter of 45mm, an inner diameter of 6mm, and a height of 70mm.

[0077] Step 2: Assemble the mold according to the order of gas inlet, auxiliary vortex platform, deposition chamber, and gas outlet, put the preform into it, and place it in a high-temperature vacuum furnace. Deposit the preform according to the following process parameters: deposition temperature 1150°C, atmospheric pressure 3500Pa, methane: 20ml / min, hydrogen 300ml / min, carrier gas hydrogen 10ml / min, argon 450ml / min, the molar mass ratio of hydrogen to MTS is 10:1. Deposit for 60h, then cool down naturally, repeat 2 times. The preform was removed from the graphite mold to obtain a 0.45 g / cm3 C / Cx-SiCy composite.

[0078] Step 3: Grinding the outer surface of the composit...

Embodiment 3

[0082] Example 3. Cylindrical co-deposited carbon-rich C / Cx-SiCy composites were prepared by traditional CVI method.

[0083] Step 1: Prepare the 2.5D needle-punched carbon felt (density 0.41g / cm3) preform into a hollow cylinder with an outer diameter of 40mm, an inner diameter of 18mm, and a height of 70mm.

[0084] Step 2: Assemble the mold according to the order of gas inlet, traditional CVI rectification hole deposition platform, deposition chamber, and gas outlet, put the preform into it, and place it in a high-temperature vacuum furnace. Deposit the preform according to the following process parameters: deposition temperature 1100°C, atmospheric pressure 5000Pa, methane: 20ml / min, hydrogen 200ml / min, carrier gas hydrogen 16ml / min, argon 600ml / min, the molar mass ratio of hydrogen to MTS is 10:1. Deposit for 52h, then cool down naturally, repeat 2 times. The preform was removed from the graphite mold to obtain 0.49 g / cm 3 C / Cx-SiCy composites.

[0085] Step 3: Grind ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com