A method for obtaining high magnetic sintered NdFeB by hot isostatic pressing and low temperature sintering

A technology of low-temperature sintering and hot isostatic pressing, applied in the direction of magnetic objects, magnetic materials, electrical components, etc., can solve the problems of grain growth and other problems, and achieve the effect of uniform grain boundary phase distribution, good fluidity, and fine grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

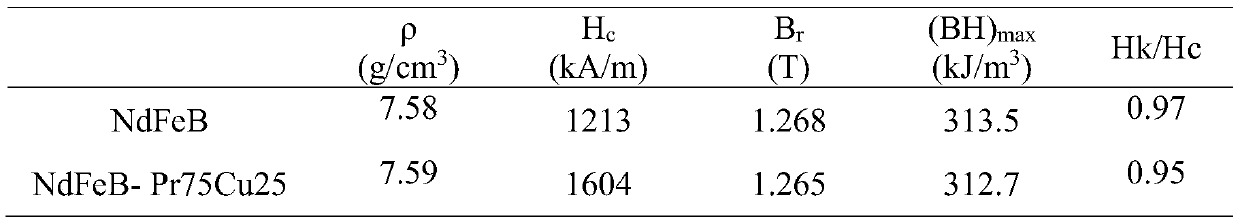

Embodiment 1

[0024] 1.0cm thick NdFeB magnet with a density of 85% is covered with Pr75Cu25 ingot particles, and the particle size is 1-5mm;

[0025] Step 1: The NdFeB magnetic powder is oriented and formed under a magnetic field of 1.2T, and the blank is semi-densified and sintered in a vacuum sintering furnace at a sintering temperature of 850°C, kept for 3 hours, and the density is 85%;

[0026] Step 2: Put the semi-dense NdFeB magnet in step 1 in a glass tube, and cover its surface with Dy75Cu25 ingot particles, and then vacuum seal the glass tube with a vacuum degree of 10 -2 Above Pa;

[0027] Step 3: Put the sample of the vacuum glass sealed tube prepared in step 2 in a graphite crucible, then place it in a hot isostatic pressing machine, perform hot isostatic pressing low-temperature sintering and tempering, apply a pressure of 50 MPa, and sinter The temperature is 800°C, heat preservation for 1h, then annealing at 500°C for 2h, and slow cooling;

[0028] Step 4: The prepared NdF...

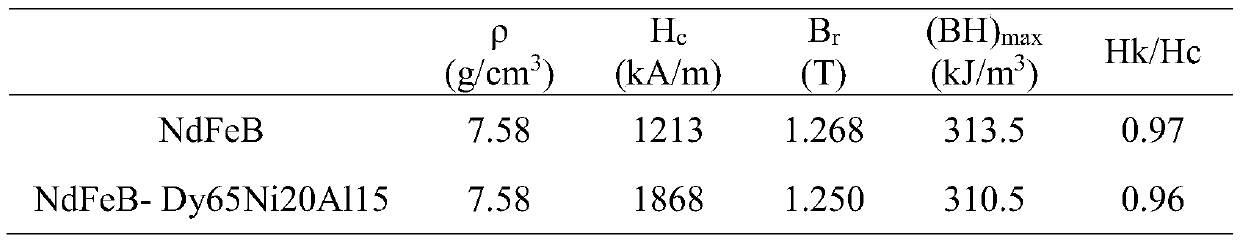

Embodiment 2

[0034] The surface of NdFeB magnet with a thickness of 1.5cm and a density of 90% is covered with Dy65Ni20Al15 ingot particles, and the particle size is 1-5mm;

[0035] Step 1: The NdFeB magnetic powder is oriented and formed under a magnetic field of 1.5T, and the blank is semi-densified and sintered in a vacuum sintering furnace. The sintering temperature is 900°C, kept for 2 hours, and the density is 90%;

[0036] Step 2: Put the semi-dense NdFeB magnet in step 1 in a glass tube, and cover the surface with Dy65Ni20Al15 ingot particles, and then vacuum seal the glass tube with a vacuum degree of 10 -2 Above Pa;

[0037] Step 3: Put the sample of the vacuum glass sealed tube prepared in step 2 in a graphite crucible, then place it in a hot isostatic pressing machine, perform hot isostatic pressing low-temperature sintering and tempering, apply a pressure of 80MPa, and sinter The temperature is 850°C, keep warm for 0.5h, then anneal at 450°C for 3h, and cool slowly;

[0038]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com