Complex machining center

A composite machining center and machining unit technology, applied in the direction of metal processing equipment, manufacturing tools, and other manufacturing equipment/tools, can solve the problems of reduced productivity, a large amount of labor time, and the inability to operate auxiliary shaft equipment 20, etc., to improve work efficiency , The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

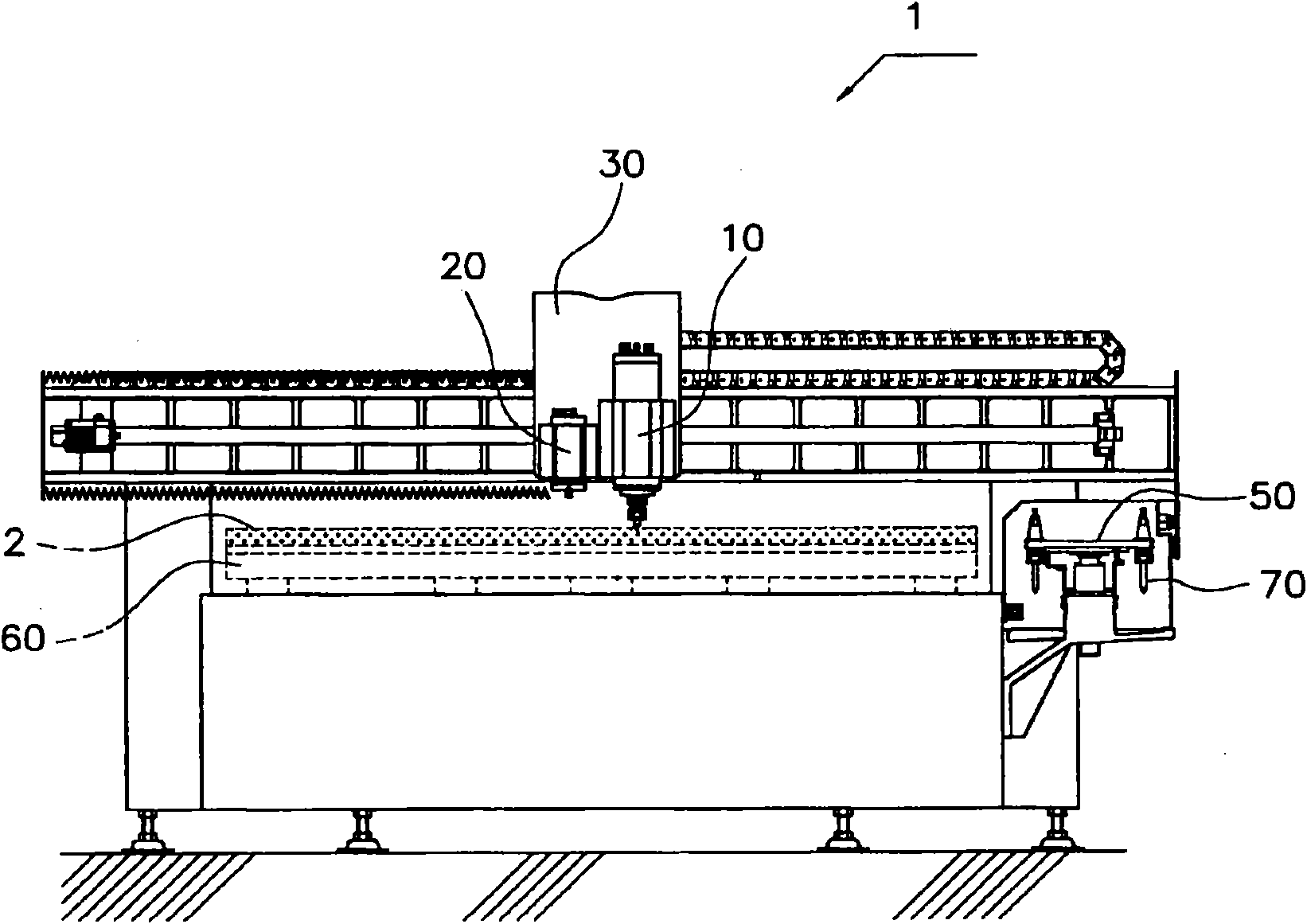

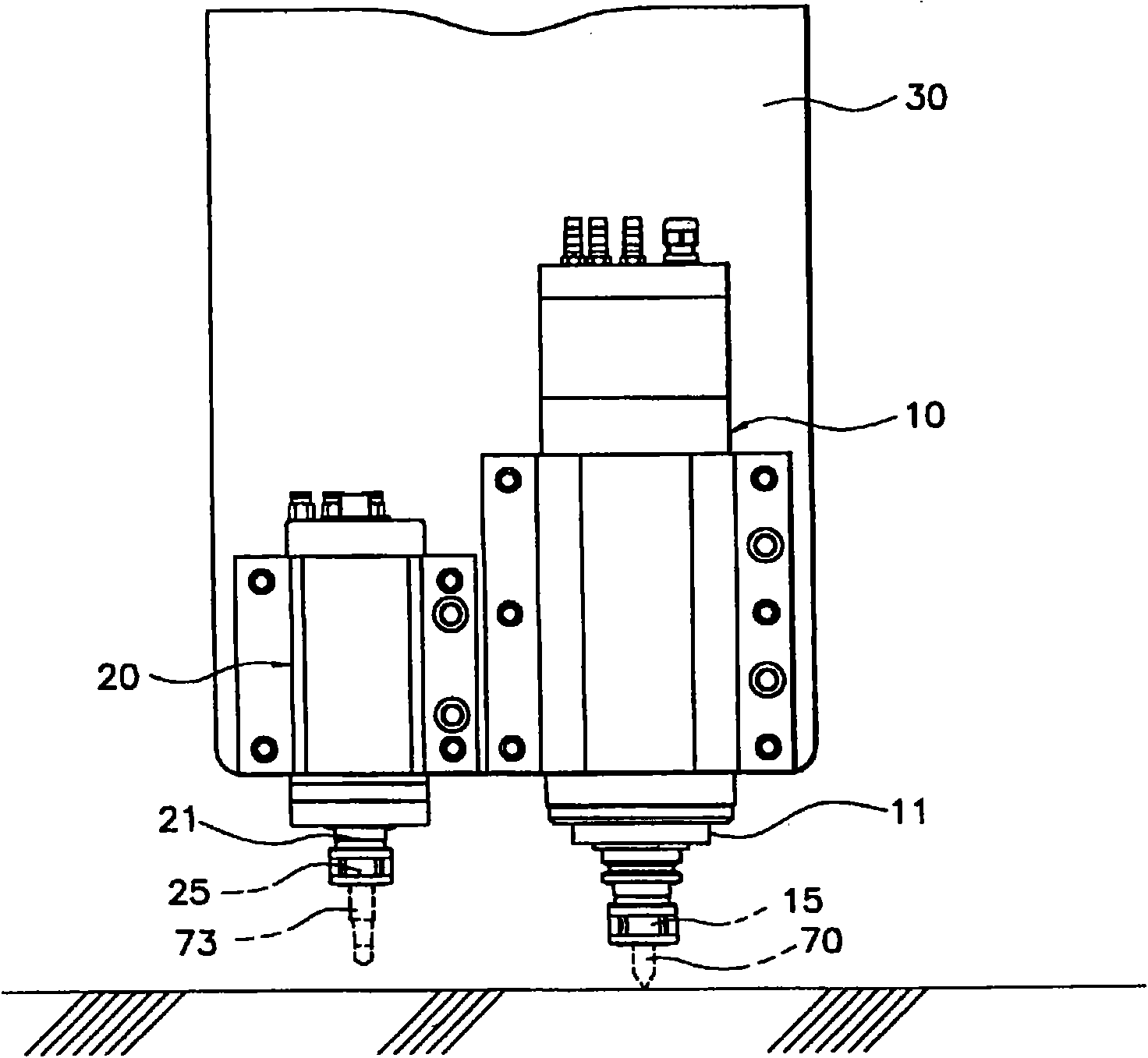

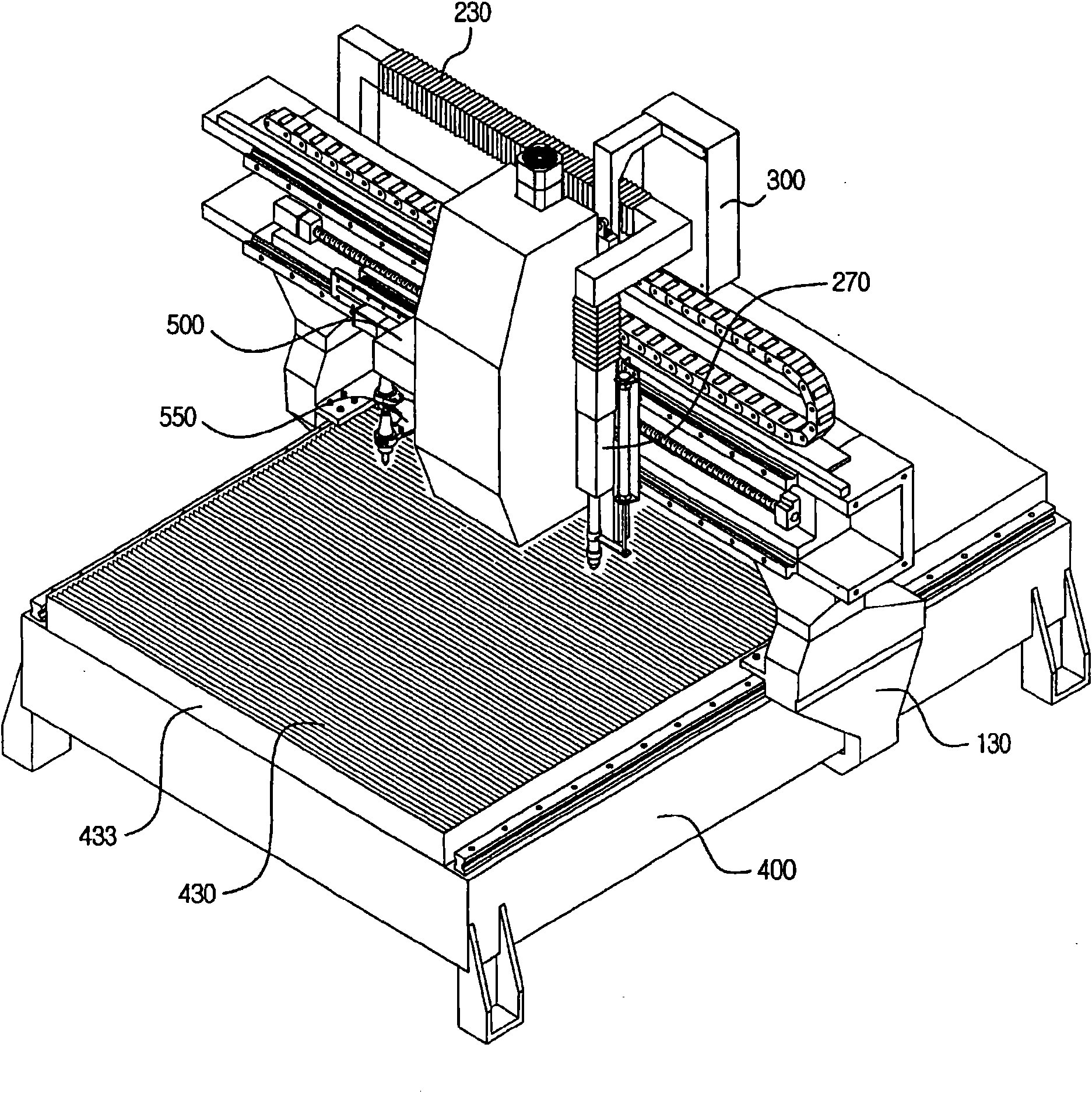

[0040] The compound machining center according to the present invention comprises a base frame 400, an X-direction positioning block 130 installed on the base frame 400, at least one Y-direction positioning block 150 arranged on at least one side of the X-direction positioning block 130, and a Y-direction positioning block 150 located on the Y-direction positioning block 130. At least one Z direction positioning block 610 , 650 in front of the direction positioning block 150 .

[0041] The workbench 433 is arranged on the base frame 400 .

[0042] The table 433 disposed on the base frame 400 can be reciprocated by the transfer unit 700 in the longitudinal direction of the base frame.

[0043] In an exemplary embodiment, the rotation table 450 connected to the second rotation unit 470 may be disposed on the work table 433 .

[0044] The second rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com