Key cap and method for making key cap

A keycap and cap body technology, applied to the keycap with patterns on it and its production field, can solve the problems of time-consuming, time-consuming, large process variation, etc., and achieve the advantages of saving process time, increasing bonding strength, and inhibiting peeling effect of possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

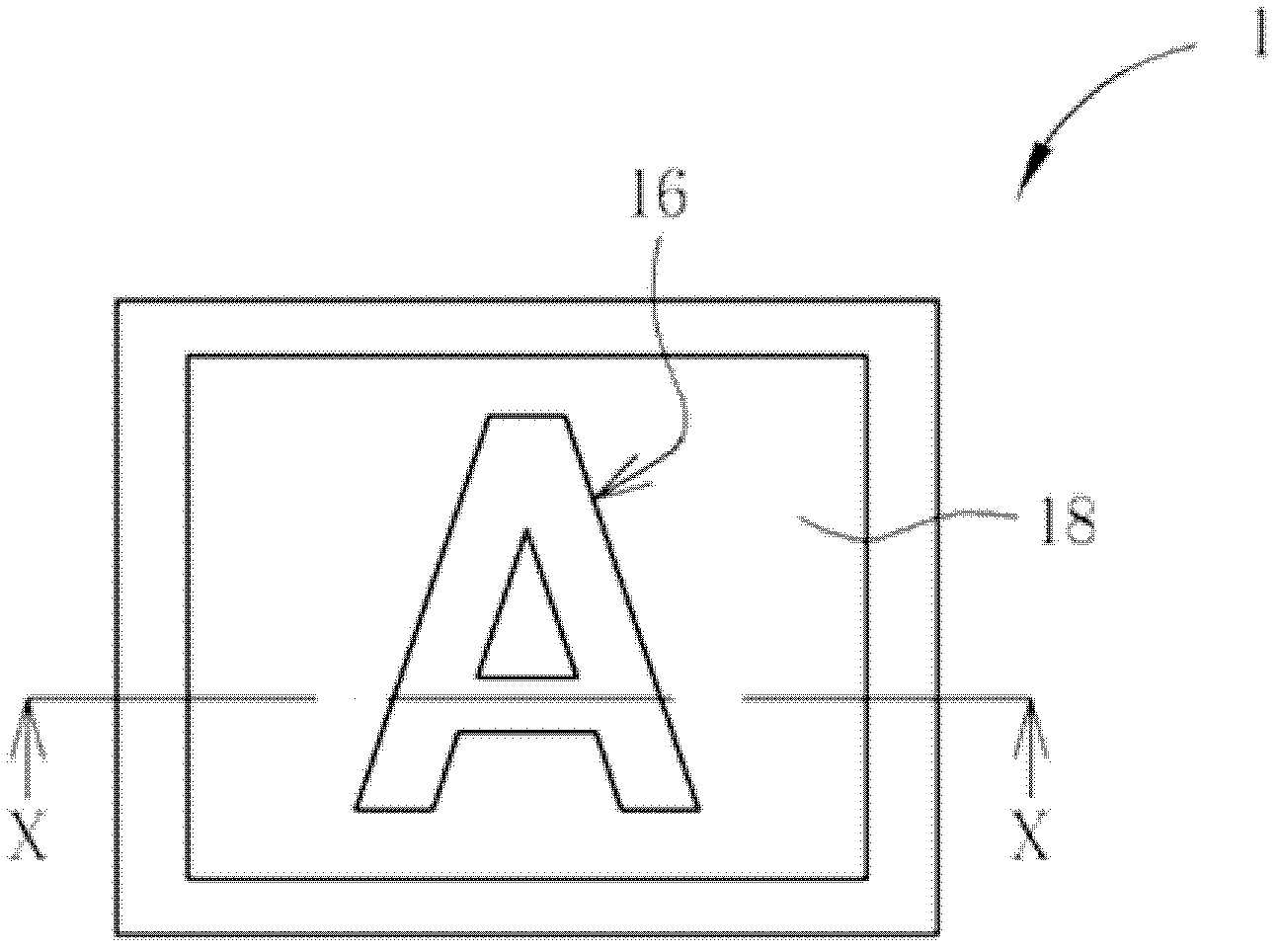

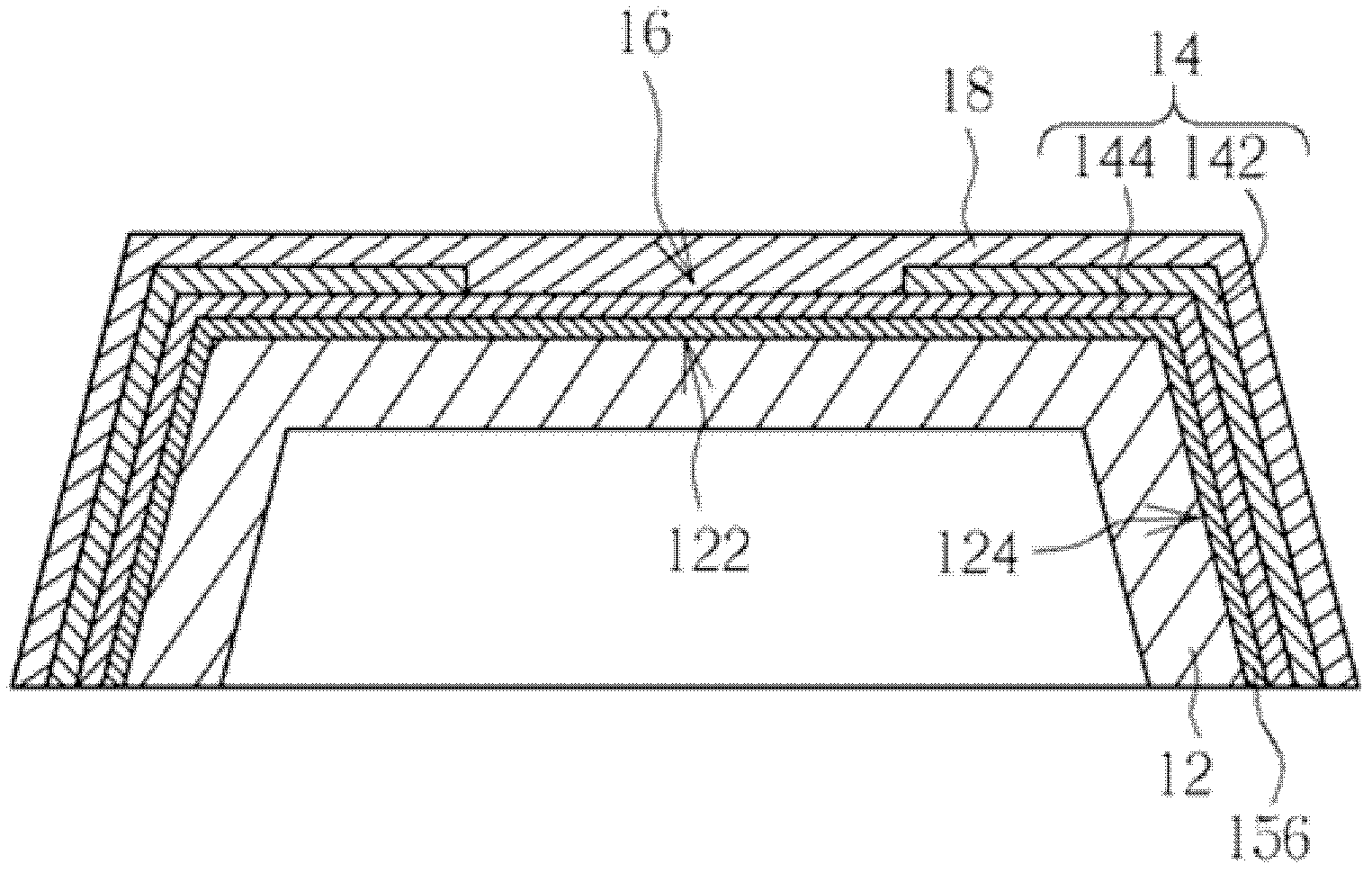

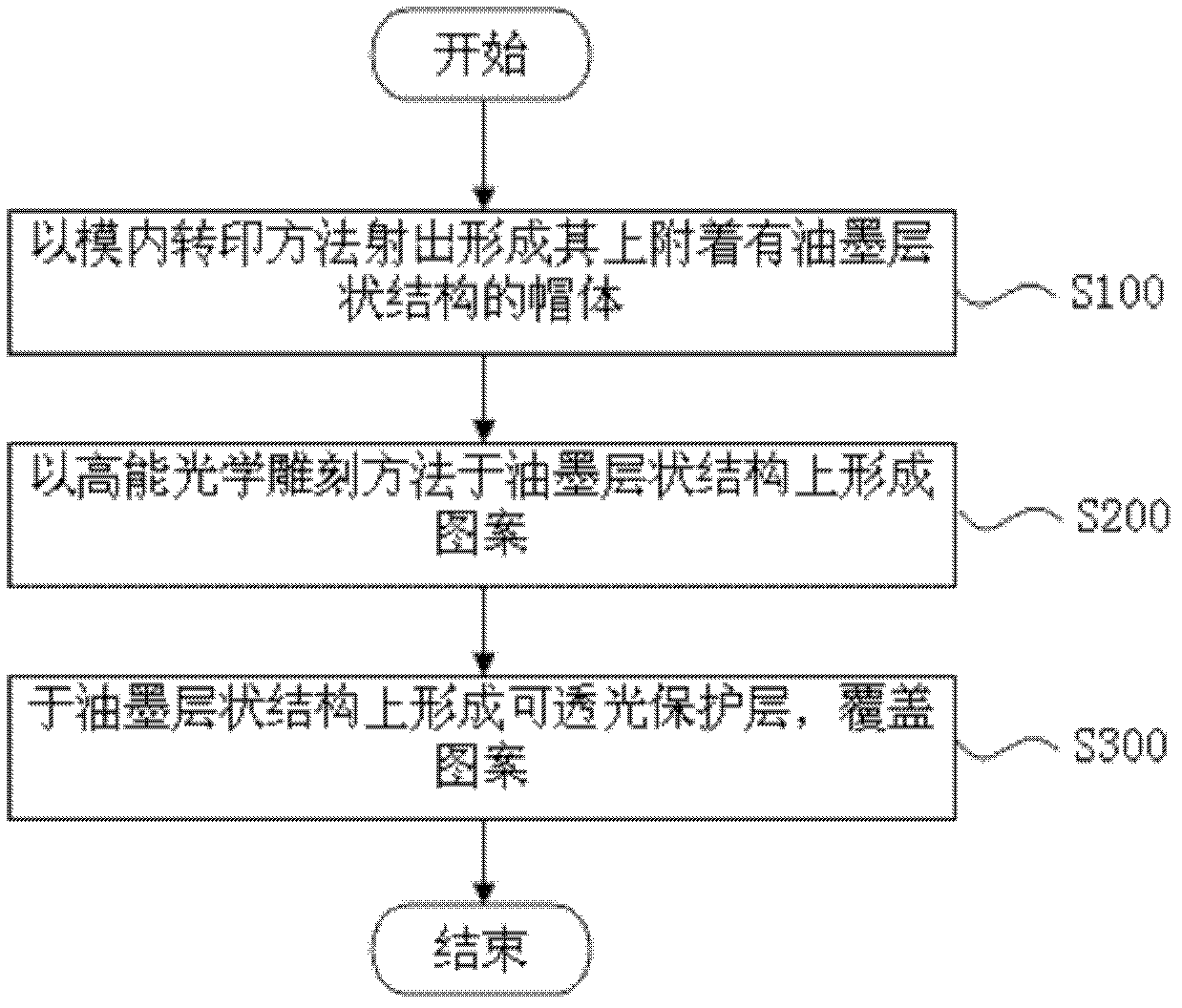

[0041] see Figure 1 to Figure 3 , figure 1 It is a top view of a keycap 1 according to a preferred embodiment of the present invention, figure 2 for figure 1 A cross-sectional view of the middle keycap 1 along the line X-X, image 3 It is the main flowchart of the method for making keycaps according to the present invention. As shown in step S100, the method for making a keycap mainly uses in-mold transfer printing to form the cap body 12 with an ink layered structure 14 attached thereon; as shown in step S200, the method for making a keycap is followed by The high-energy optical engraving method forms a pattern 16 on the ink layered structure 14. In this embodiment, the pattern 16 is a letter A, but the invention is not limited thereto. Finally, as shown in step S300 , in the method for manufacturing a keycap, a light-transmittable protective layer 18 is formed on the ink layered structure 14 to cover the pattern 16 . In this way, the production of the keycap 1 utilize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com