Method for preparing cation polystyrene template based on porous materials

A technology for polystyrene and porous materials, which is applied in the field of preparation of quaternary ammonium salt cationic submicron polystyrene templates, and can solve the problems of easy deformation of holes in porous materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

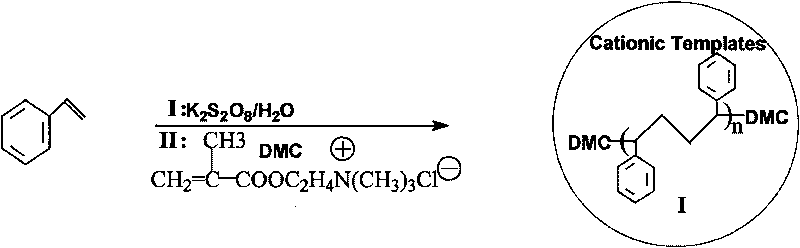

Method used

Image

Examples

Embodiment 1

[0027] Put 72g of deionized water, 8g of styrene and 0.16g of potassium persulfate into a 150ml four-necked bottle, and at a stirring speed of 350rpm, pass nitrogen gas to remove the air for about 20 minutes, then use a pre-adjusted 70 ℃ warm water was poured into the constant temperature water bath rapidly, and kept 70 ℃ unchanged. After 1.5 hours to be reacted, under nitrogen protection, the mixed solution of 0.4g DMC and deionized water (with the volume ratio of deionized water 2: 1, The same below), inject into the four-neck bottle with a micro-injector in several times, one injection every half hour, each injection (10 μl), a total of three injections, and then two injections, one injection per hour, each injection is (25 μl) . Then inject another injection every 3 minutes (50 μl) until all the remaining DMC is injected. After the injection is completed, the polymerization is extended for about 12 hours to make it fully aggregated. After the polymerization is completed, ...

Embodiment 2

[0029] Since the dissolution of the template is closely related to the content of DMC inside polystyrene, this is because with the increase of DMC, the polymer molecular chains are more loosely combined, and the polymer is more soluble. Therefore, in this example, it is specially studied to increase the DMC content in the early stage of DMC (here, before 5 hours). Except that the DMC content changes, other formulas are the same as in Example 1. After 1.5 hours of reaction, under the protection of nitrogen, the mixed solution of 0.4g DMC and deionized water is injected into the reaction bottle with a micro-injector. One injection every half hour (10 μl per injection), and then two injections, one injection every hour, each injection is (50 μl). Then inject another injection every 3 minutes (50 μl) until all the remaining DMC is injected. After the injection is completed, the polymerization is extended for about 12 hours to make it fully aggregated. After the polymerization is ...

Embodiment 3

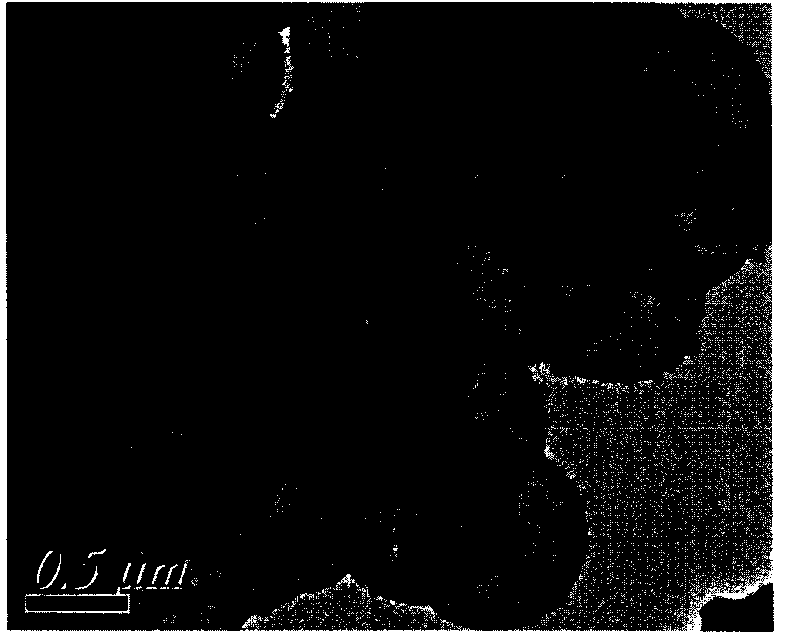

[0031] In order to increase the content of quaternary ammonium salt cations on the surface of the template, this example specifically studies how to increase the surface grafting amount of DMC. According to the formula of Example 2 before the polymerization reaction 5 hours, then inject a needle every 3 minutes, each needle is (50 μ l), and inject about 1.2 g of DMC together. After the injection is completed, the polymerization is extended for about 12 hours, so that It polymerizes well. After the polymerization is completed, the polymer is suction-filtered, washed and separated with a water-based microporous membrane (0.22 μm), and finally a monodisperse cationic submicron polystyrene template with about 15% DMC is prepared. from figure 2 It can be seen that the dispersibility of this template is very good (TEM image).

[0032] In order to explore the performance of this template that can be dissolved under milder conditions after the porous material is prepared, the catio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com