Preparation method of high specific surface area nano-cerium oxide

A technology of nano-cerium oxide and high specific surface area, applied in chemical instruments and methods, inorganic chemistry, rare earth metal compounds, etc., can solve the problems of difficult post-processing, unsuitable for industrial production, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 5.2kg cerium carbonate (CeO 2 ≥45%) with 2.91LHNO 3 Dissolve, and add 12.69L deionized water to make solution A, add 46.8g polyethylene glycol, and then add 1.65kg ammonium citrate to make solution C. Take 26.6L1.5mol / L of NH 4 HCO 3 into solution D. Then, under the condition of stirring, add solution C dropwise to solution D. During the dropping process, the pH value of solution D decreases continuously. After solution C is dropped, add ammonia solution dropwise until the pH value of the reaction system is 6.5. ±0.5; At this time, a white precipitate is formed, stir the precipitate for 0.5 hours, filter the precipitate, and wash with deionized water for 3 to 4 times, then dry the precipitate in static air at 80°C for 12 hours, and then roast at 450°C hours, the heating rate is 200°C / hour, the product is cerium oxide, and the specific surface area is 122.6m 2 / g (measured by BET method), the particle size is 20-70nm.

Embodiment 2

[0030] 2.1kg Ce(NO 3 ) 3 ·6H 2 O and 4.83L of deionized water were made into solution A, in which 24.9g of polyethylene glycol was added, and then 0.207kg of ammonium chloride was added into solution C. Take 12.1L1.2mol / L of NaHCO 3 into solution D. Then, under the condition of stirring, the solution D is added dropwise to the solution C. During the dropping process, the pH value of the solution C increases continuously. After the solution D is dropped, the ammonia solution is added dropwise until the pH value of the reaction system is 6.5±0.5; At this time, a white precipitate is formed, and then stir the precipitate for 0.5 hours, filter the precipitate, and wash it with deionized water for 3 to 4 times, then dry the precipitate in static air at 100°C for 12 hours, and then bake it at 480°C 2 hours, the heating rate is 150°C / hour, the product is cerium oxide, and the specific surface area is 110.8m 2 / g (measured by BET method), and its particle size is 40-70nm.

Embodiment 3

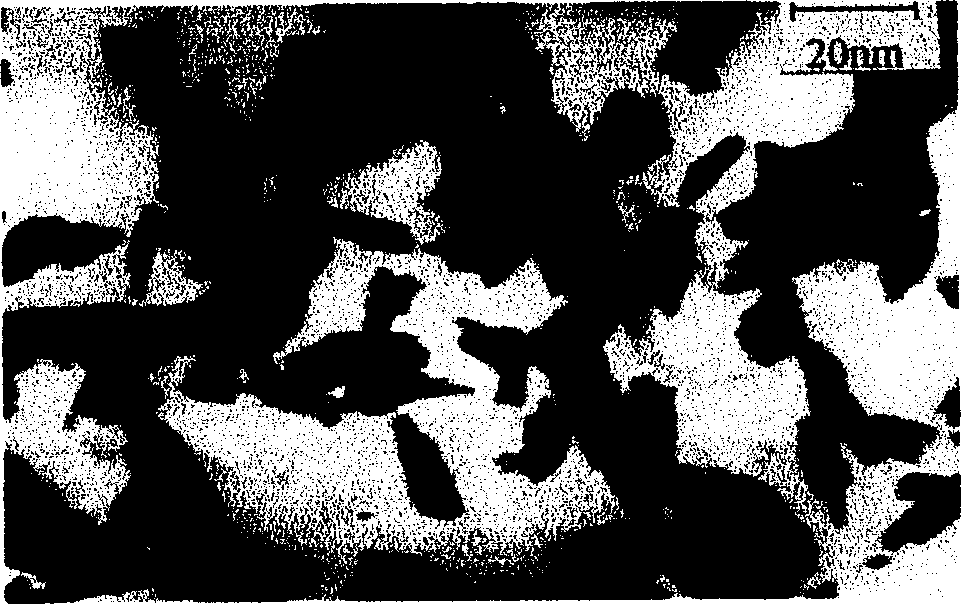

[0032] 1.2kg cerium oxide (CeO 2 ≥99%) with 1.49LHNO 3 Dissolve, and add 4.51L deionized water to make solution A, add 48g polyethylene glycol, and then add 0.891g ammonium tartrate to make solution C. Take 10.5L of 2.0mol / L NaOH to make solution D. Then, under the condition of stirring, the solution D is added dropwise to the solution C. During the dropping process, the pH value of the solution C increases continuously. After the solution D is dropped, the ammonia solution is added dropwise until the pH value of the reaction system is 6.5±0.5; At this time, a white precipitate is formed, and then stir the precipitate for 0.3 hours, filter the precipitate, and wash it with deionized water for 3 to 4 times, then dry the precipitate in static air at 120°C for 6 hours, and then bake it at 420°C 2 hours, the heating rate is 200°C / hour, the product is cerium oxide, and the specific surface area is 145.2m 2 / g (measured by BET method), its particle size is 20-50nm (see attached ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com