Rapid CVD compacting method of carbon/carbon heat field structure product for single crystal furnace

A technology of carbon thermal field and single crystal furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

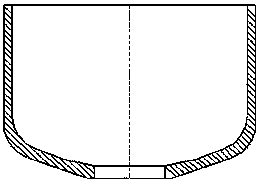

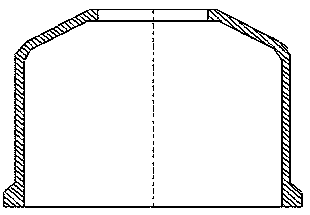

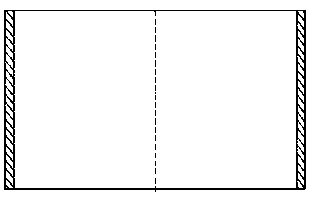

Image

Examples

Embodiment 1

[0030] Embodiment 1 A method for rapid CVD densification of carbon / carbon thermal field structure products for single crystal furnaces, comprising the following steps:

[0031] (1) Assembling the thermal field of the single crystal furnace: the thermal field of the single crystal furnace includes graphite tray 8, gas distribution tool 7, heat preservation cylinder 2, flow guide tube 4, crucible 3, gas guide cylinder 5, and gas limiting tool 1; The graphite material tray 8 and the gas distribution tool 7 are located at the bottom of the thermal field of the single crystal furnace, and an insulation tube 2 is arranged on it. The inside of the insulation tube 2 is provided with a guide tube 4 and a crucible 3, and the guide tube 4 is located in the crucible. 3, the air-guiding tube 5 passes through the hole at the bottom of the center of the crucible 3 and the air-guiding tube 4, and the gas-limiting tool 1 is arranged above the insulating tube 3. During design, the thickness of ...

Embodiment 2

[0035] (1) Assembling the thermal field of the single crystal furnace: the thermal field of the single crystal furnace includes graphite tray 8, gas distribution tool 7, heat preservation cylinder 2, flow guide tube 4, crucible 3, gas guide cylinder 5, and gas limiting tool 1; The graphite material tray 8 and the gas distribution tool 7 are located at the bottom of the thermal field of the single crystal furnace, and an insulation tube 2 is arranged on it. The inside of the insulation tube 2 is provided with a guide tube 4 and a crucible 3, and the guide tube 4 is located in the crucible. 3, the air-guiding tube 5 passes through the hole at the bottom of the center of the crucible 3 and the air-guiding tube 4, and the gas-limiting tool 1 is arranged above the insulating tube 3. During design, the thickness of the graphite material tray 7 is not less than 50 mm, and the thickness of the gas distribution tool 6 is not less than 40 mm, both of which are made of graphite; There is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com