Graphitization furnace and graphitization production method for synthetic graphite negative electrode material

A technology of graphitization furnace and production method, which is applied in the chemical industry, sustainable manufacturing/processing, climate sustainability, etc. It can solve the problems of unsatisfactory production method, high cost of graphitization, low product purity, etc., and achieve shortening power supply Heating time, improved environmental protection, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

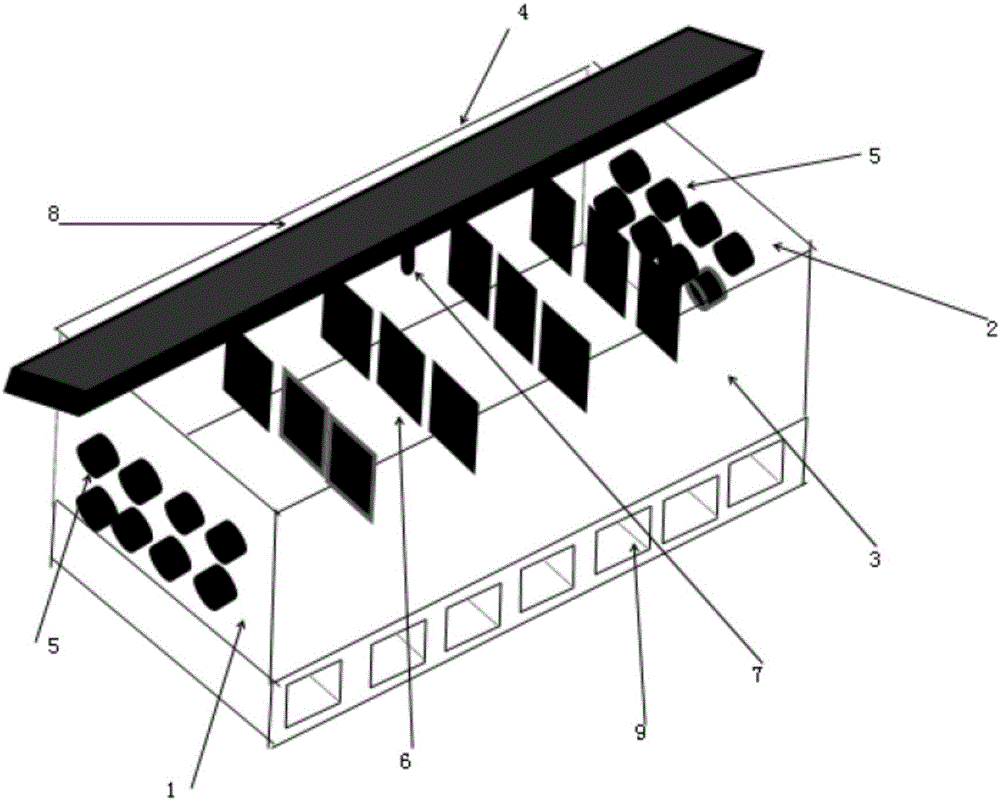

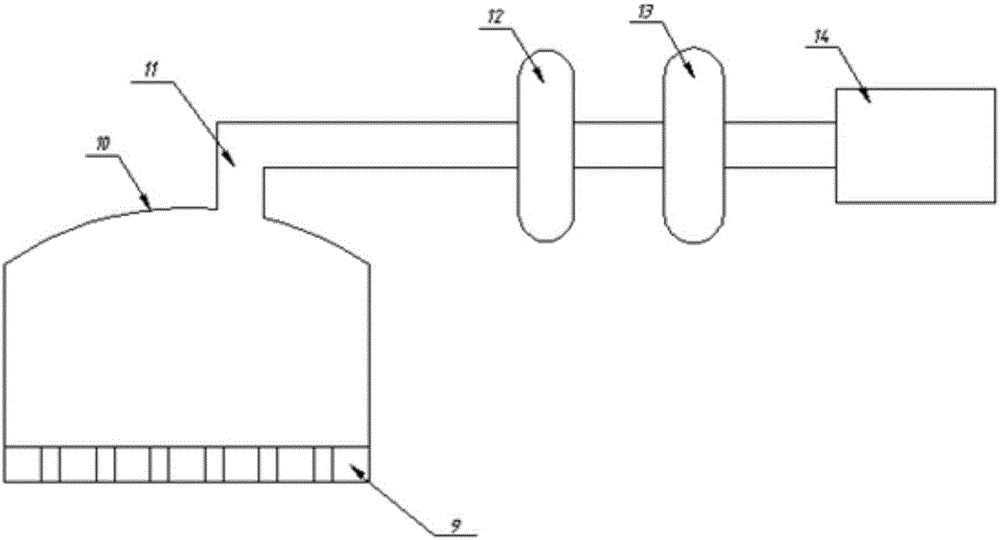

Embodiment 1

[0047] Take 1000KG calcined petroleum coke with particle size diameter D50 of 18μm and load it into figure 1 High temperature treatment in medium graphitization furnace, initial current density of power transmission is 20A / cm 2 , the power transmission time is 24 hours, and the current density is increased to 28A / cm in the later stage of power transmission 2 Raise the temperature of the product in the furnace to 2800°C, keep it warm for 12 hours, stop power supply to the furnace, cool for about 28 hours, start the suction system to discharge, and obtain qualified products.

Embodiment 2

[0049] Take 1000KG pitch coke with particle size diameter D50 of 22μm and load it into figure 1 High temperature treatment in medium graphitization furnace, initial current density of power transmission is 25A / cm 2 , the power transmission time is 16 hours, and the current density is increased to 28A / cm in the later stage of power transmission 2 Raise the temperature of the product in the furnace to 3000°C, keep it warm for 10 hours, stop power supply to the furnace, cool for about 30 hours, start the suction system to discharge, and get qualified products.

Embodiment 3

[0051] Take 1000KG coal coke with a particle size diameter D50 of 11 μm and load it into figure 1 High temperature treatment in medium graphitization furnace, initial current density of power transmission is 20A / cm 2 , the power transmission time is 25 hours, and the current density is increased to 28A / cm in the later stage of power transmission 2 Raise the temperature of the product in the furnace to 3200°C, keep it warm for 10 hours, stop power supply to the furnace, cool for about 30 hours, start the suction system to discharge, and get qualified products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com