A low-cost low-expansion long-cycle natural graphite-based composite material and its preparation method and application

A technology of composite materials and natural graphite, which is applied in the field of low-cost, low-expansion, long-cycle natural graphite-based composite materials and its preparation, can solve the problem of low bulk density, reduce the charging amount of graphitization furnace, and increase the cost of graphitization of negative electrode materials and other problems, to achieve the effect of increasing the furnace charge, excellent high-temperature cycle performance, and improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

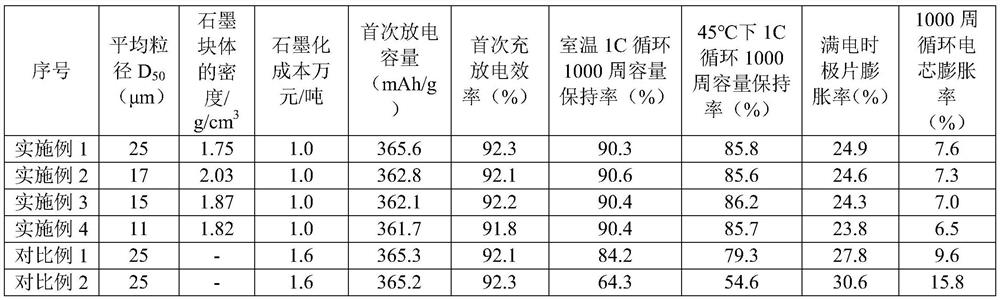

Examples

preparation example Construction

[0050] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0051] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

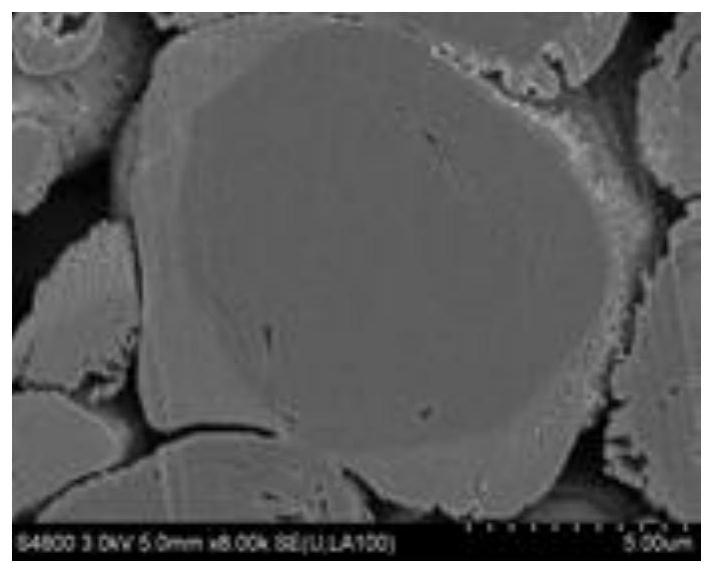

Embodiment 1

[0053] Natural flake graphite (D 50 200μm) 100kg into the kneading pot, kneaded at 200°C for 30 minutes, cooled to room temperature, and then pulverized the cooled product in a jet mill to D 50 It is 27μm, and finally it is shaped in the shaping machine to get D 50 25μm spherical graphite. Spherical graphite was treated with cold isostatic pressing equipment at 100 MPa for 20 minutes to obtain graphite block. Put the graphite block directly into the graphitization furnace, treat it at 2800°C for 4 hours and cool it down, break up and sieve the graphitized material to obtain the material. The high-softening-point asphalt with a softening point of 200°C was crushed to 3 μm in an impact mill, and mixed with the above-mentioned prepared materials at a mass ratio of 0.8:100. 2 Treat at 1200°C under protection for 4 hours, cool to room temperature, disperse, sieve, and demagnetize to obtain a natural graphite-based composite material.

Embodiment 2

[0055] Natural flake graphite (D 50 160μm) 100kg into the kneading pot, kneaded at 100°C for 20 minutes, cooled to room temperature, and then pulverized the cooled product in a jet mill to D 50 It is 19μm, and finally it is shaped in a shaping machine to obtain D 50 17μm spherical graphite. After the spherical graphite is processed by cold isostatic pressing equipment at 200 MPa for 10 minutes, graphite block is obtained. Put the graphite block directly into the graphitization furnace, treat it at 2800°C for 3 hours and cool it down, break up and sieve the graphitized material to obtain the material. Put the materials prepared above into a rotary furnace, and in an argon atmosphere with a flow rate of 100 L / min and an environment of 800 ° C, feed methane at a flow rate of 1 L / min for 2 hours, and then switch to feed argon, After cooling to room temperature, disperse, sieve, and demagnetize, the natural graphite-based composite material can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com