Vacuum melting rapid hardening equipment and manufacturing method of rapidly hardened alloy

A technology of vacuum smelting and manufacturing method, which is applied in the manufacture of inductors/transformers/magnets, magnetic materials, electrical components, etc., can solve the problems of the influence of the magnetic properties of rare earth permanent magnet materials, the high content of oxygen and other impurities, and the inconvenience of the production process, etc. Achieve the effect of improving performance and consistency, improving utilization, and improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

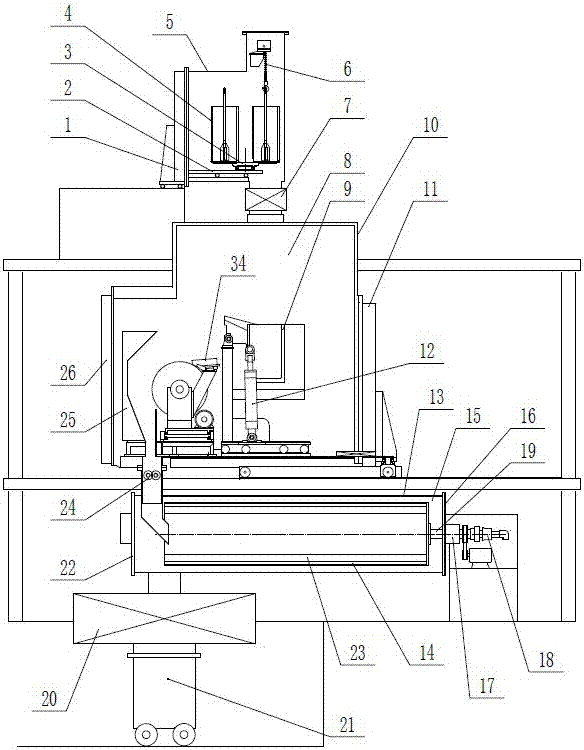

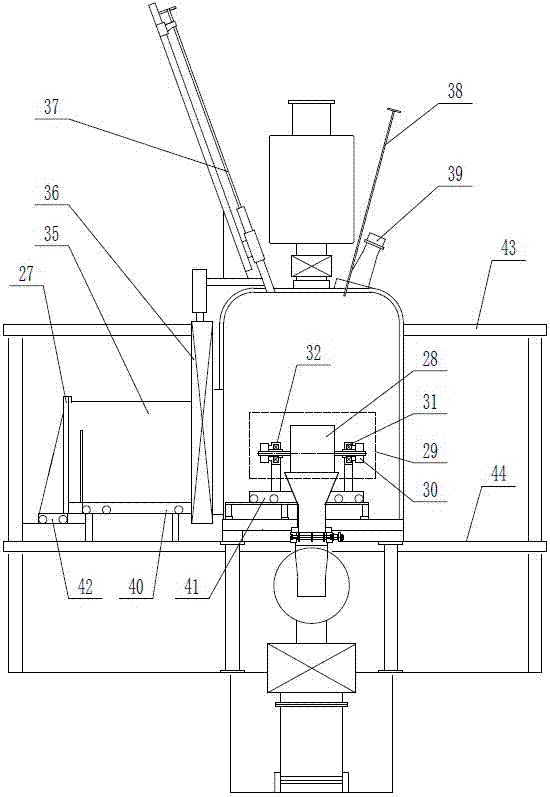

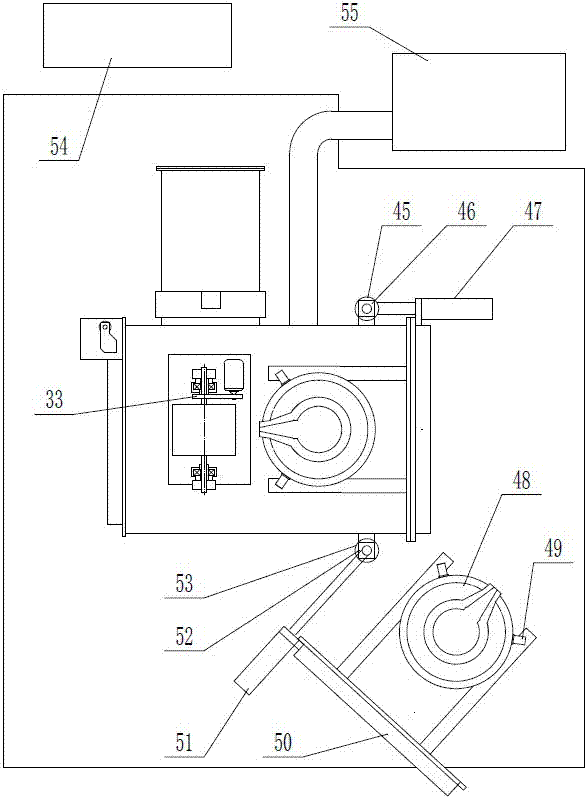

Method used

Image

Examples

Embodiment 1

[0048]The raw materials of praseodymium neodymium alloy, terbium metal, dysprosium iron, pure iron, ferroboron, gallium metal, zirconium metal, cobalt metal, aluminum metal and copper metal are formulated into Pr 6.3 Nd 23.1 Dy 2 Tb 0.6 B 0.95 co 1.2 Zr 0.12 Ga 0.1 al 0.2 Cu 0.2 Fe 余量 Put pure iron and ferroboron into No. 1 material basket, put pure iron, ferroboron and a small amount of praseodymium neodymium alloy into No. 2 material basket, put praseodymium neodymium alloy, dysprosium iron, metal terbium, and metal gallium Put the metal zirconium, metal cobalt, metal aluminum, and metal copper into the No. 4 material basket, and then the operation includes: (1) Send the 4 material baskets into the vacuum feeding chamber of the vacuum melting and quick-setting equipment, pump After vacuuming, open the vacuum valve between the vacuum feeding chamber and the vacuum melting chamber; (2) Through the cooperation of the lifting device, the 4-station turntable and the reci...

Embodiment 2

[0054] Raw materials containing praseodymium neodymium alloy, terbium metal, dysprosium iron, pure iron, ferroboron, gallium metal, zirconium metal, cobalt metal, aluminum metal, copper metal and NdFeB scrap are formulated into Pr 6.3 Nd 23.1 Dy 2 Tb 0.6 B 0.95 co 1.2 Zr 0.12 Ga 0.1 al 0.2 Cu 0.2 Fe 余量 The alloy raw materials, wherein, the NdFeB waste content accounts for 10-60% of the total weight; put pure iron and ferroboron into the No. 1 basket, put the NdFeB waste into the No. 2 basket, and melt the NdFeB The slag cleaning device is loaded into the No. 3 material basket, and the praseodymium-neodymium alloy, dysprosium iron, terbium metal, gallium metal, zirconium metal, cobalt metal, aluminum metal, and copper metal are loaded into the No. 4 material basket, and the subsequent operation steps include: (1) Send the material basket into the vacuum feeding chamber of the vacuum melting and quick-setting equipment, and open the vacuum valve between the vacuum feedi...

Embodiment 3

[0060] Raw materials containing rare earth alloys, pure iron, ferroboron and metal zirconium are formulated into alloys shown in Table 6 by weight percentage, pure iron and ferroboron are packed into No. 1 and No. 2 material baskets, and No. 3 rare earth alloys are packed into Material basket, put the metal zirconium into the No. 4 material basket, and the subsequent operations include: (1) Send the material basket into the vacuum feeding chamber of the vacuum melting and quick-setting equipment, and open the vacuum valve between the vacuum feeding chamber and the vacuum melting chamber after vacuuming ; (2) Through the cooperation of the lifting device, the 4-station turntable and the reciprocating trolley, the raw materials of No. 1 and No. 2 baskets are added to the crucible of the vacuum melting chamber under vacuum conditions, and heated to a temperature range of 600-1500 °C; (3) Add the raw materials of No. 3 and No. 4 baskets to the crucible of the vacuum melting chamber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| velocity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com