Wide-body melting furnace for producing electronic display glass

An electronic display and melting furnace technology, applied in glass production, glass furnace equipment, glass manufacturing equipment, etc., can solve the problems of current action path changes, operating environment changes, heating electrode replacement difficulties, etc., to achieve convenient modification and improve melting furnace The effect of high productivity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

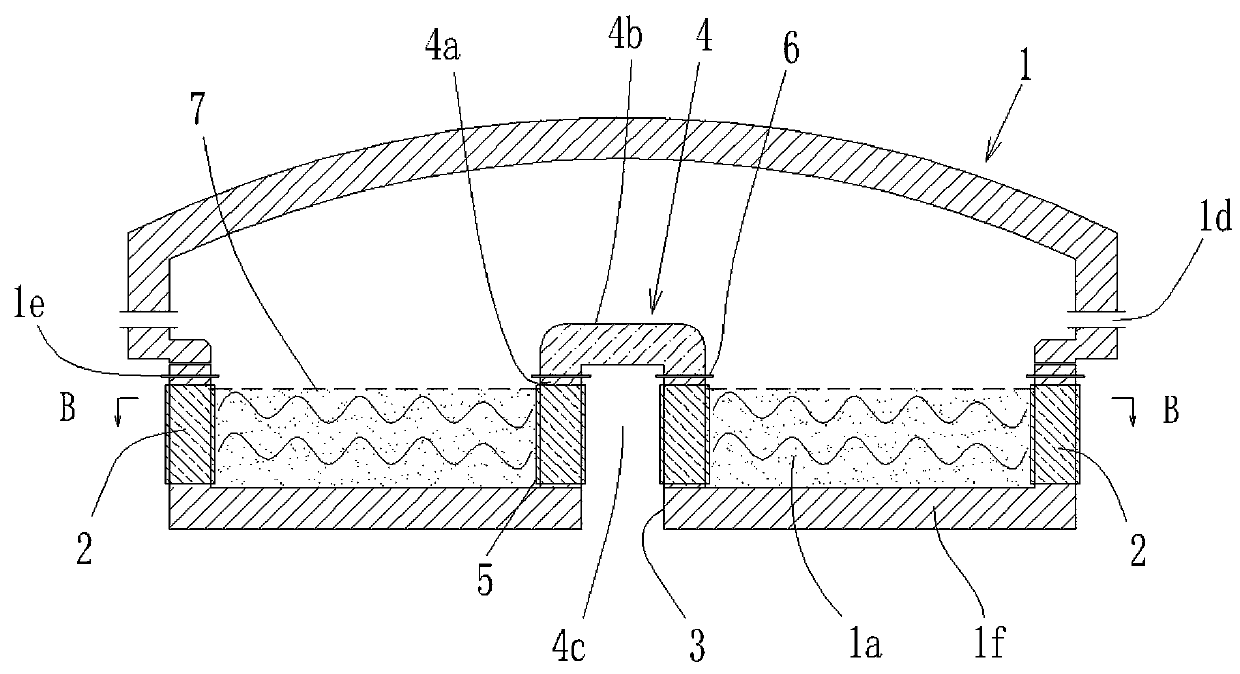

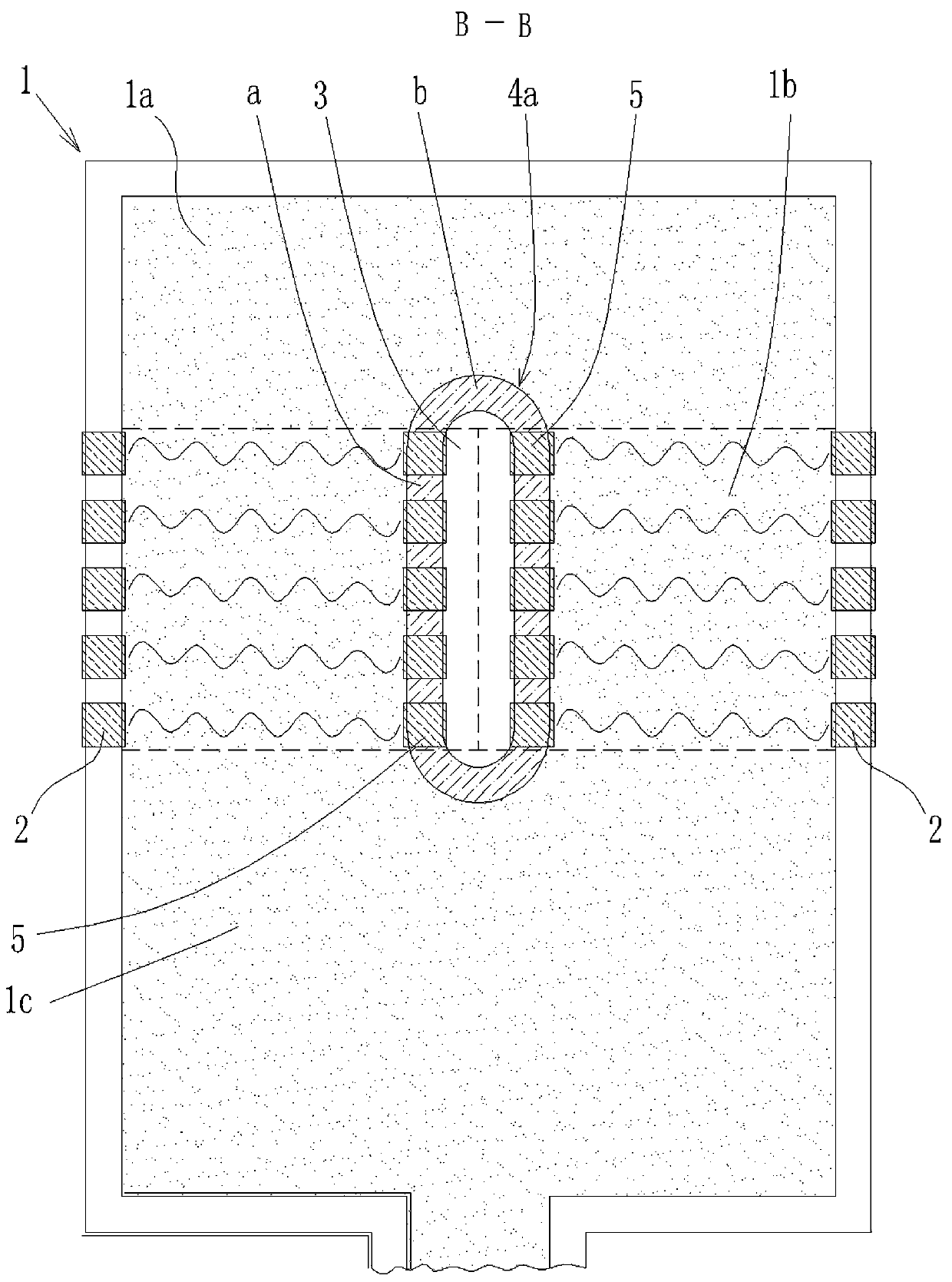

[0015] Such as figure 1 and 2 As shown, a wide-body melting furnace for the production of electronic display glass includes a melting furnace 1 whose width is twice that of the original melting furnace. twice the size of the kiln.

[0016] In the melting furnace 1, the melting furnace is divided into a feeding part 1a, a melting part 1b and a clarification part 1c along the raw material flow direction, and one end of the clarification part 1c is connected to the subsequent process. The parapet walls on both sides of the melting part 1b are provided with smoke outlets 1d, and a group of first oxygen-enriched gas guns 1e is perforated on the pool wall below each smoke outlet 1d. There are two rows of oxygen-enriched gas guns 1e, which are symmetrically distributed on the pool walls on both sides of the melting furnace. A group of first heating electrodes 2 are arranged on the pool walls below the first oxygen-enriched gas guns 1e. The electrodes 2 are divided into two rows, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com