Application of silica powder to polycrystalline silicon cast ingot preparation

A technology for polycrystalline silicon and polycrystalline silicon blocks, which is applied in the directions of polycrystalline material growth, crystal growth, single crystal growth, etc., can solve the problems of inability to bring economic benefits, low product life of minority carriers, insufficient silicon powder melting material, etc. The effect of reducing the amount of furnace, reducing the preparation cost, and improving the lifetime of the minority carrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

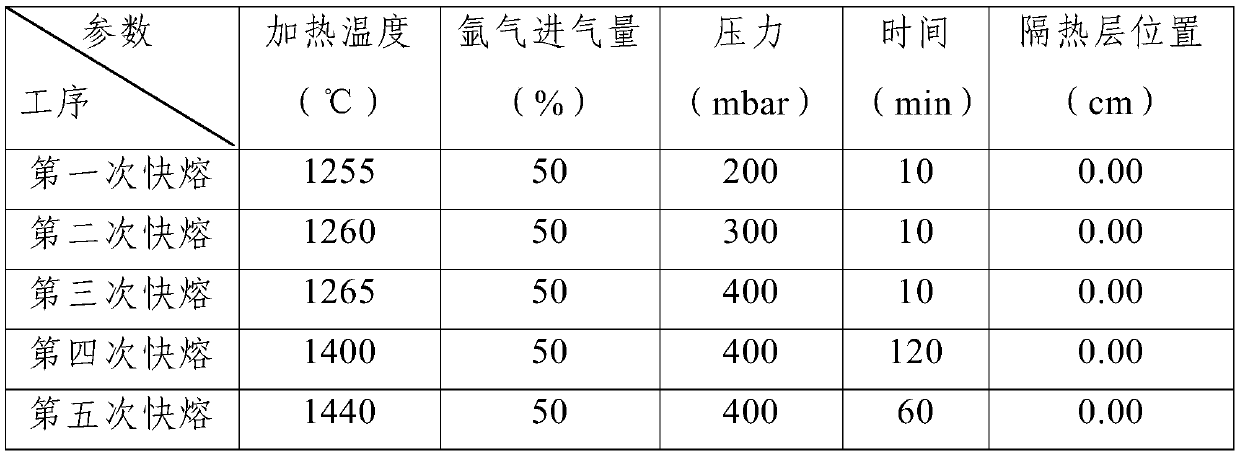

[0037] The method of the present embodiment comprises the following steps:

[0038] Step 1. Loading: Put 50kg of silicon powder, 170kg of silicon regrind, 150kg of silicon granules, 250kg of polysilicon blocks, 180kg of polysilicon rods, and 50kg of silicon seeds into the quartz crucible of the ingot furnace as silicon for ingot casting. material;

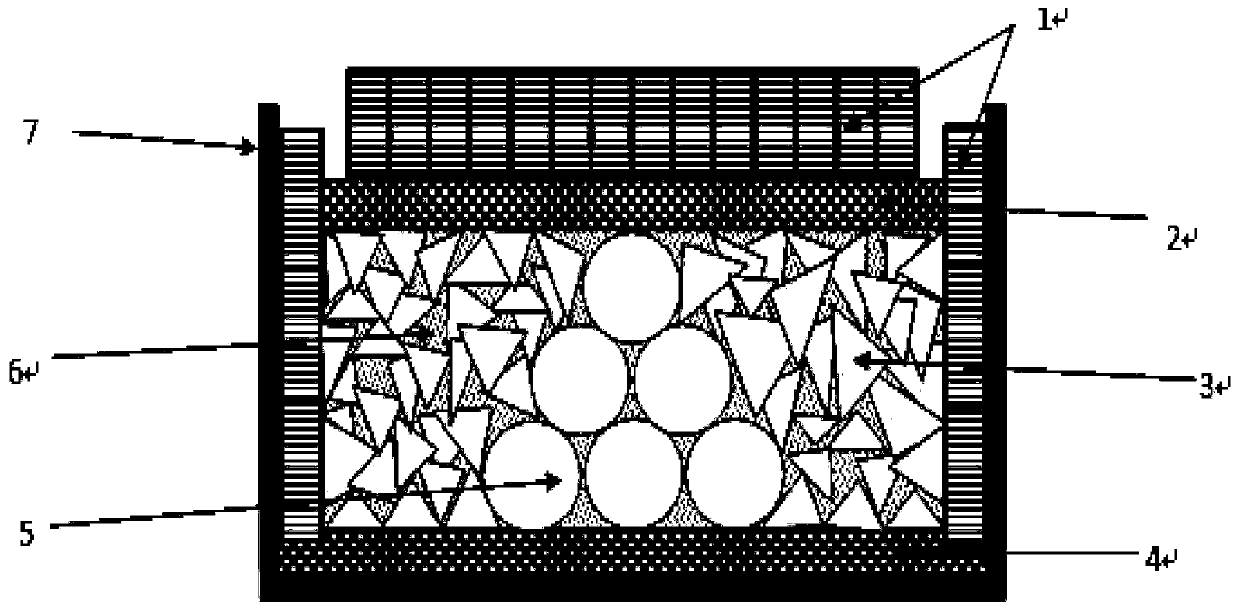

[0039] The mass purity of the silicon powder is 99.9999%, and the particle size is 0.02mm to 0.149mm. The mass purity of the silicon particles is 99.9999999%, and the particle size is greater than 1mm. The mass purity of the polycrystalline silicon block and polycrystalline silicon bar is both 99.9999999%, the particle size of the silicon seed crystal is 1 mm to 4 mm; the loading method of the silicon material in the quartz crucible is as follows: the silicon seed crystal is first loaded into the bottom layer of the quartz crucible until its thickness is 15 mm, and then along the parallel Adhere to the inner wall of the quartz cru...

Embodiment 2

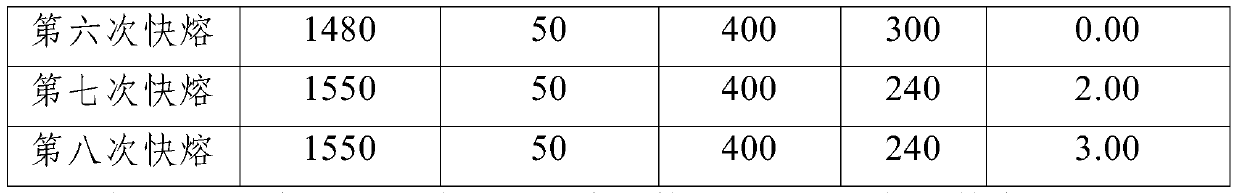

[0065] The difference between this embodiment and Example 1 is that in the charging process of step 1, 170kg of silicon regrind, 150kg of silicon powder, 150kg of silicon granules, 150kg of polysilicon blocks, 180kg of polysilicon rods, and 50kg of silicon seeds are loaded Put it into the quartz crucible of the ingot furnace as the silicon material for ingot casting; the time of the sixth fast melting described in step 301 is 330 minutes, and the heating temperature of the seventh fast melting and the eighth fast melting are both 1540°C.

Embodiment 3

[0067] The difference between this embodiment and Embodiment 1 is that in the charging process of step 1, 170kg of silicon regrind, 250kg of silicon powder, 150kg of silicon granules, 50kg of polysilicon blocks, 180kg of polysilicon rods, and 50kg of silicon seed crystals are packed Put it into the quartz crucible of the ingot furnace as the silicon material for ingot casting; the time of the sixth fast melting described in step 301 is 360min, and the heating temperatures of the seventh fast melting and the eighth fast melting are both 1530°C; The heating temperatures of the first slow melting and the second slow melting in step 302 are both 1525°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com