Special carbon material internal heat serial graphitizing production apparatus

A carbon material, internal heat series connection technology, applied in the field of special carbon material internal heat series graphitization production equipment, can solve the problems of high maintenance cost, large amount of cooling water, long power cycle, etc. The effect of small amount and short power-on time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

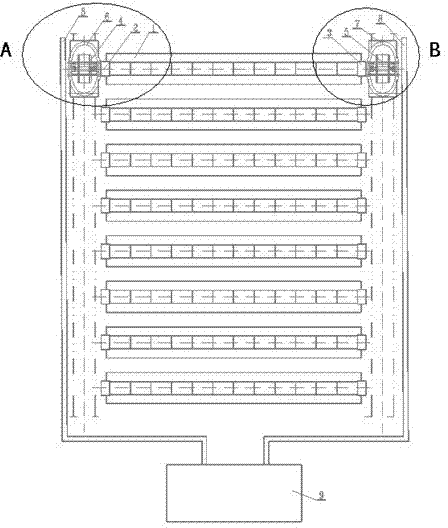

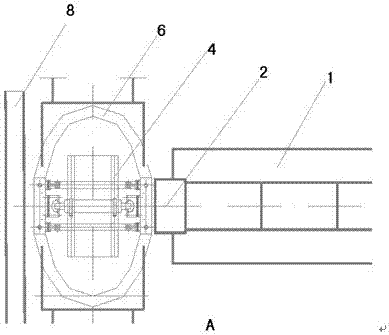

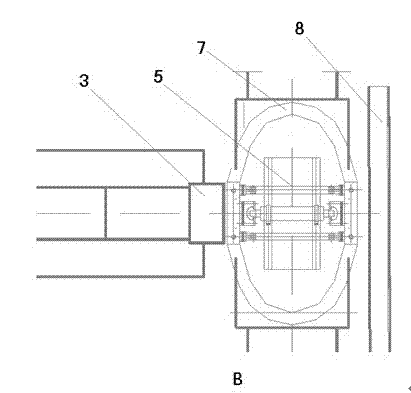

[0021] Such as Figure 1 to Figure 3 As shown, a special carbon material internal heat series graphitization production device includes 8 graphitization furnaces 1, and 8 graphitization furnaces 1 are energized in turns and operate in cycles; each graphitization furnace 1 has only one material box, and the material box Refractory brick masonry is used, and a furnace head conductive electrode 2 and a furnace tail conductive electrode 3 are respectively arranged at both ends of the graphitization furnace 1; the furnace head two-way pushing device 4 and the furnace tail two-way pushing device 5 have two directions of left and right. The ability to push, the furnace head pushing device 4 can connect the furnace head soft busbar 6 with the furnace head conductive electrode 2 and the fixed busbar 8 respectively, and the furnace tail two-way pushing device 5 can respectively connect the furnace tail soft busbar 7 to the furnace tail The electrodes 3 and the fixed busbar 8 are connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com