Continuous protective atmosphere heating high-pressure gas quenching furnace

A protective atmosphere and high-pressure gas technology is applied in the field of continuous protective atmosphere heating high-pressure gas quenching furnaces to achieve the effects of reducing the consumption of nitrogen gas for ventilation, high quenching intensity and high ventilation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

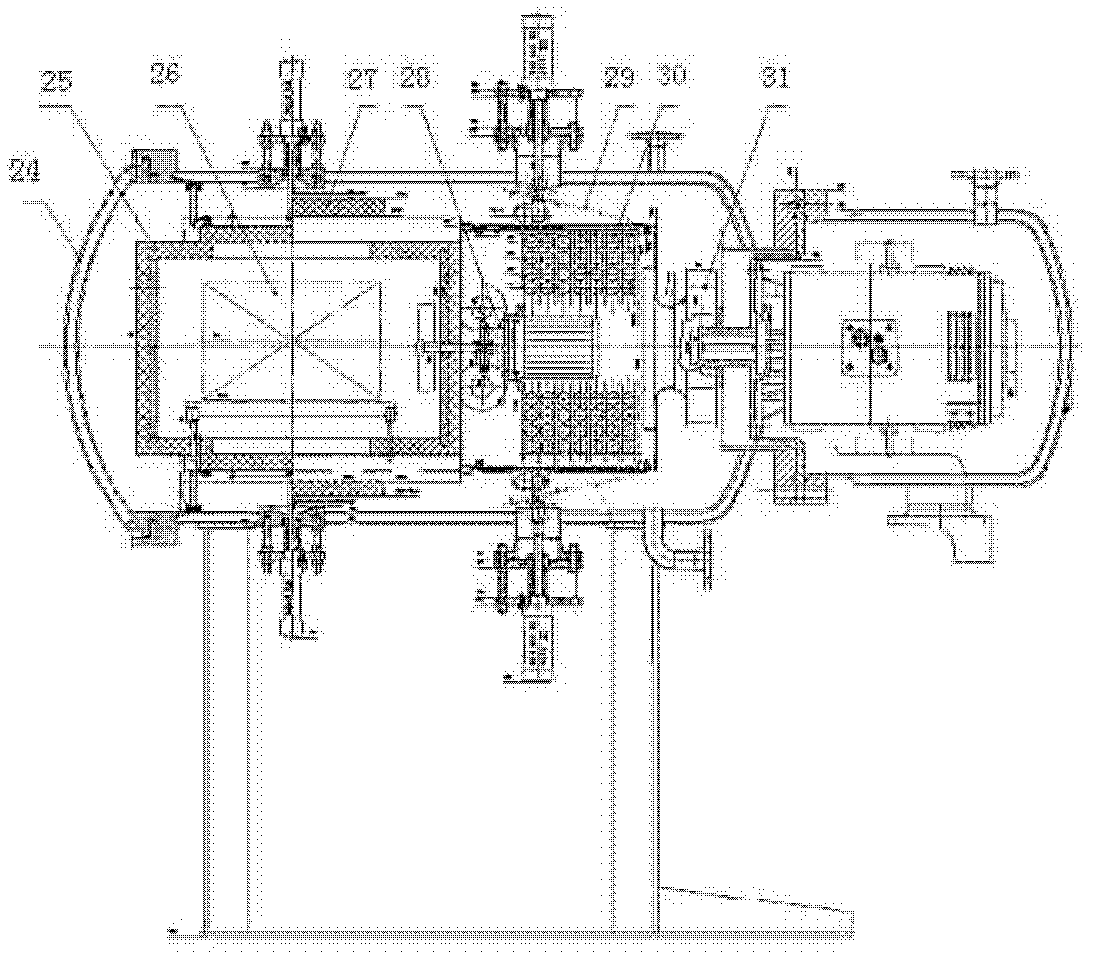

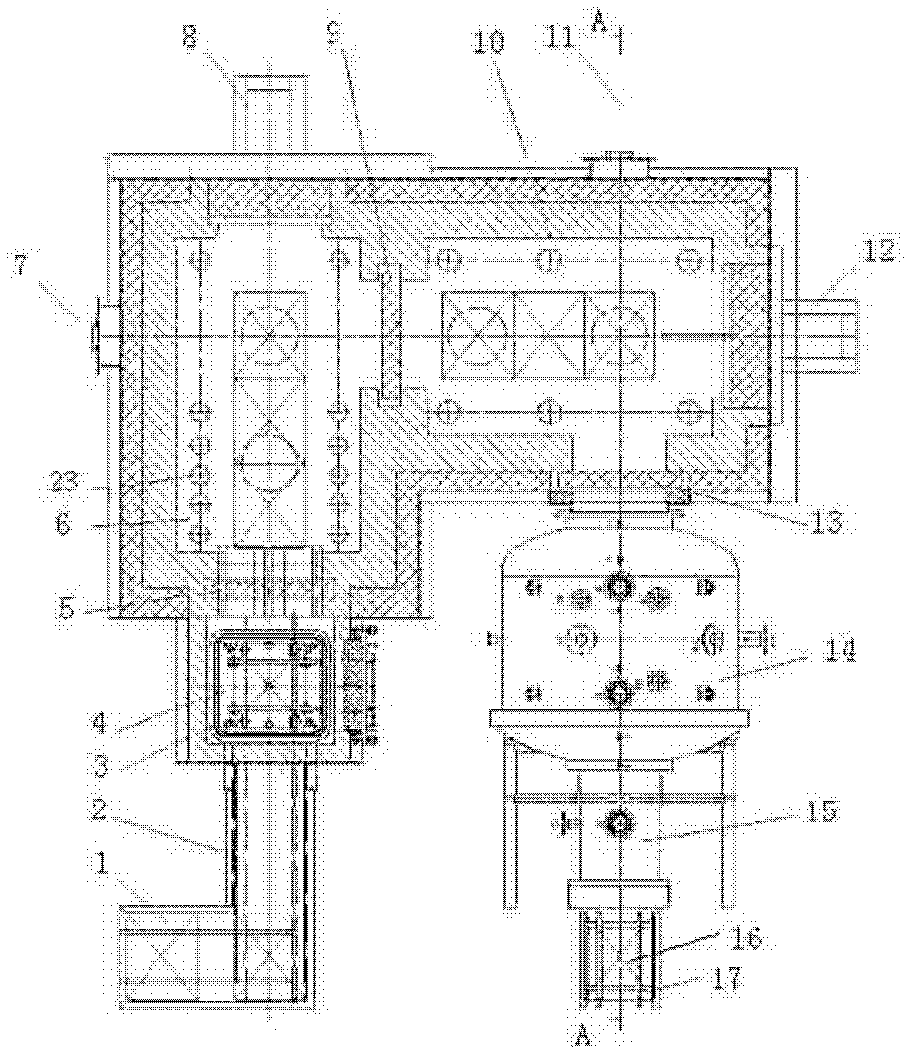

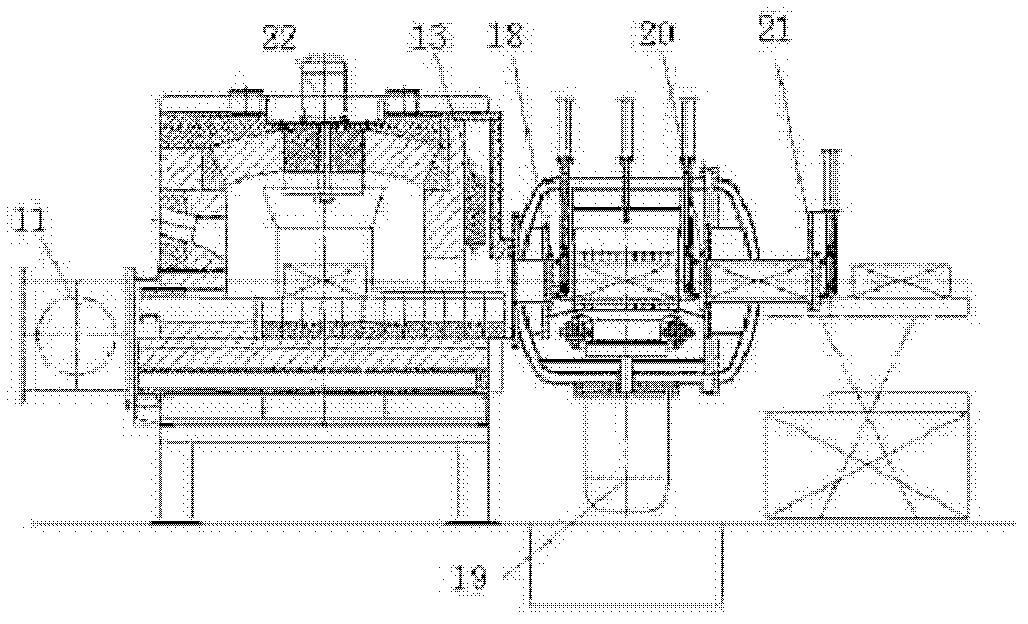

[0018] refer to figure 2 and image 3 As shown, the continuous protective atmosphere heating high-pressure gas quenching furnace includes a continuous protective atmosphere heating furnace, the heat preservation zone 10 of the protective atmosphere heating furnace is sealed and connected to the high-pressure gas quenching chamber 14, and the high-pressure gas quenching chamber 14 is sealed and connected to the vacuum ventilation discharge chamber 15 .

[0019] The protective atmosphere heating furnace comprises a vacuum ventilation front chamber 4, a heating zone 6 and a heat preservation zone 10, the vacuum ventilation front chamber 4 is a bottom charging mode, the vacuum ventilation front chamber 4 is divided into two chambers, and the lower chamber is provided with The pneumatic flap door 3 is loaded from the feeding area 1 through the feeding device 2, the lower chamber is pre-vacuumized and ventilated after horizontal loading, and the upper chamber is a transition chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com