Titanium sheet vacuum hotpressing shape righting technology

A vacuum hot pressing, thin plate technology, used in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of surface oxidation, pollution, etc., to achieve the effect of large surface area, long service life and shortened processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

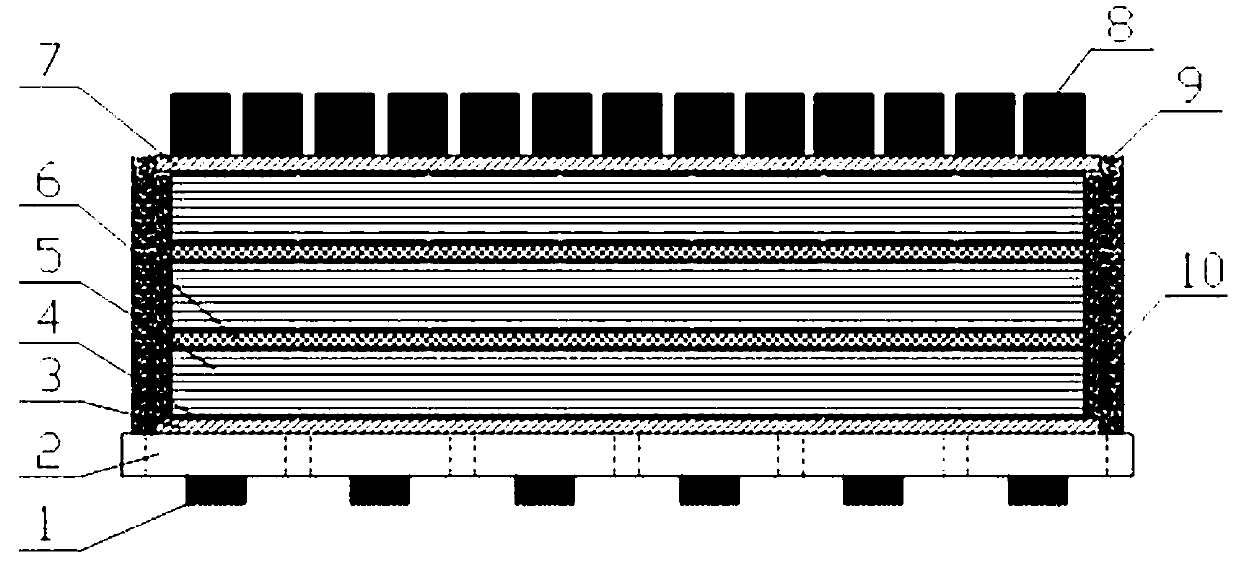

Method used

Image

Examples

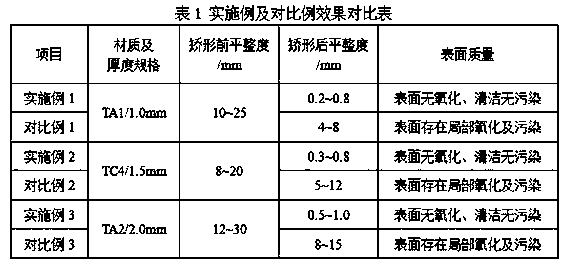

example 1

[0034] Example 1: 1.0mm thickness specification TA1 brand titanium thin plate vacuum hot pressing orthopedic annealing.

[0035] The flatness of the titanium sheet before annealing is 10~25mm. Adopt the method of the present invention to carry out material swing, wherein titanium sheet 5 is divided into two piles of piles, the total thickness of titanium sheet piles is 200mm, and every pile of titanium sheets 5 has a thickness of 100mm; the titanium chips 9 that are cleaned and fully dried are arranged as Around the titanium thin plate stacking material, and fix it with a metal mesh 10; after the material is placed, vacuum the vacuum hot-pressed orthopedic furnace to ≤1×10 -2 Pa, raise the temperature to 350 degrees Celsius for intermediate heat preservation, the heating time is 2 hours; the intermediate heat preservation time is 2.5 hours; after the intermediate heat preservation stage is over, the temperature is raised to 450 degrees Celsius to enter the hot-pressing orthope...

example 2

[0037] Example 2: 1.5mm thickness specification TC4 grade titanium thin plate vacuum hot pressing orthopedic annealing.

[0038] The flatness of the titanium sheet before annealing is 8~20mm. Adopt the method of the present invention to carry out material swing, wherein 5 titanium sheets are divided into two stacks, the total thickness of the titanium sheet stacks is 180mm, and the thickness of each stack of titanium sheets 5 is 90mm; the cleaned and fully dried titanium chips 9 are arranged on the titanium sheets Around the stacking material, and fix it with a metal mesh 10; after the material is placed, the vacuum hot-pressed orthopedic furnace is evacuated to ≤1×10 -2 Pa, raise the temperature to 400 degrees Celsius for intermediate heat preservation, the heating time is 2.5 hours; the intermediate heat preservation time is 2.5 hours; after the intermediate heat preservation stage is over, the temperature is raised to 600 degrees Celsius to enter the hot-pressing orthopedic...

example 3

[0040] Example 3: 2.0mm thickness specification TA2 brand titanium thin plate vacuum hot pressing orthopedic annealing.

[0041] The flatness of the titanium sheet before annealing is 12~30mm. Adopt the method of the present invention to carry out material swing, wherein titanium sheet 5 is divided into two piles of piles, the total thickness of titanium sheet piles 300mm, every pile of titanium sheets 5 thickness 100mm; Around the thin plate stacking material, and fix it with a metal mesh 10; after placing the material, vacuum the vacuum hot-pressing orthopedic furnace to ≤1×10 -2 Pa, raise the temperature to 350 degrees Celsius for intermediate heat preservation, the heating time is 4 hours, and the middle heat preservation time is 4 hours; after the intermediate heat preservation stage is over, the temperature is raised to 550 degrees Celsius to enter the hot-pressing orthopedic stage, the heating time is 4 hours, and the heat-pressing orthopedic stage is held for 6 hours. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com