High-strength and high-conductivity aluminum alloy used for overhead conductors and preparation method for aluminum alloy

An overhead wire and aluminum alloy technology is applied in the field of aluminum alloy materials to achieve the effects of large furnace loading, energy saving and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a method for preparing a high-strength and high-conductivity aluminum alloy, comprising the following steps:

[0031] S1. According to the element composition ratio in Table 1, select aluminum ingot 99.7, magnesium ingot 99.9, AlSi for remelting 20 Alloy, AlFe 20 Alloy, AlB 3 Alloy, AlCu 50 Alloys are batched.

[0032] Table 1 Element composition ratio content

[0033] element Si Fe Mg Cu B Cr+Mn+V+Ti content 0.62 0.27 0.68 0.07 0 0.006

[0034] S2. Add 99.7 aluminum ingots for remelting into the melting furnace to melt, and add AlB to the aluminum liquid 3 The alloy is subjected to boronization treatment; then the molten aluminum is transferred into the holding furnace, and the temperature of the holding furnace is controlled at 750-780°C, and then the magnesium ingot 99.9, AlSi 20 Alloy, AlFe 20 Alloy, AlCu 50 Put the alloy into the holding furnace and stir it electromagnetically for ≥30 minutes to ma...

Embodiment 2-3

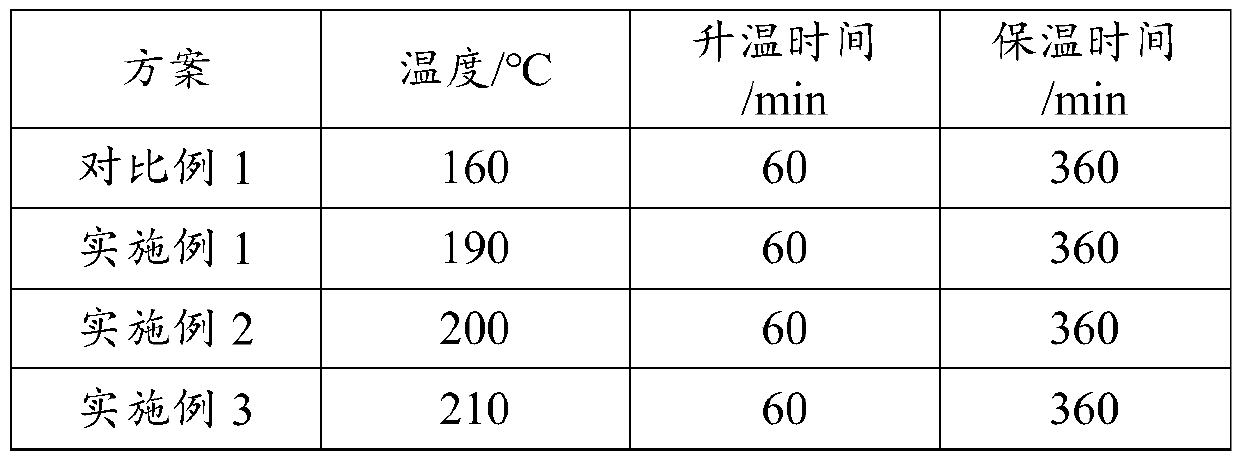

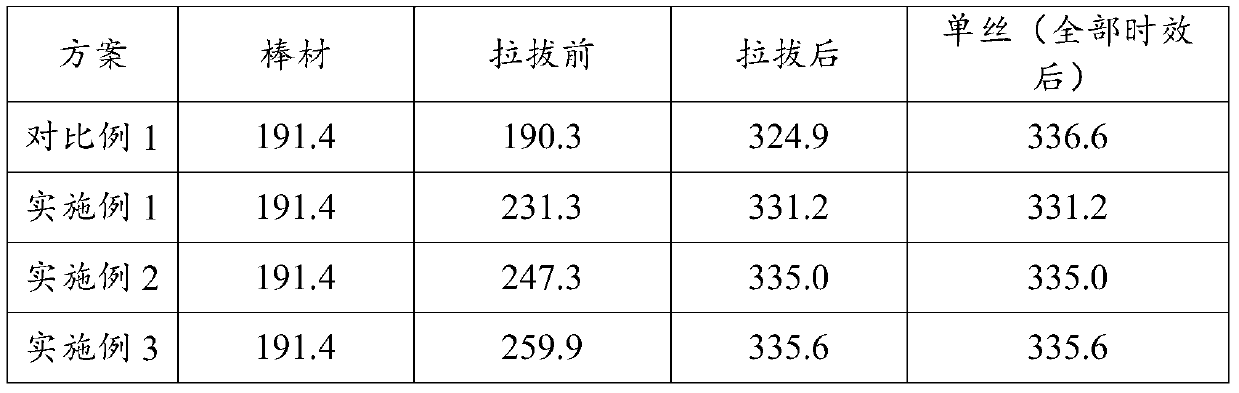

[0040] The difference between embodiment 2-3 and embodiment 1 is only the aging treatment system.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com