Method for realizing MCrAlX protective coating through ion plating deposition and device

A protective coating, ion plating technology, applied in the direction of ion implantation plating, coating, metal material coating process, etc., can solve problems such as the inability to meet the long-term stable operation of industrial production, anode pollution, etc., to achieve low loss, avoid Pollution, the effect of increasing the furnace load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

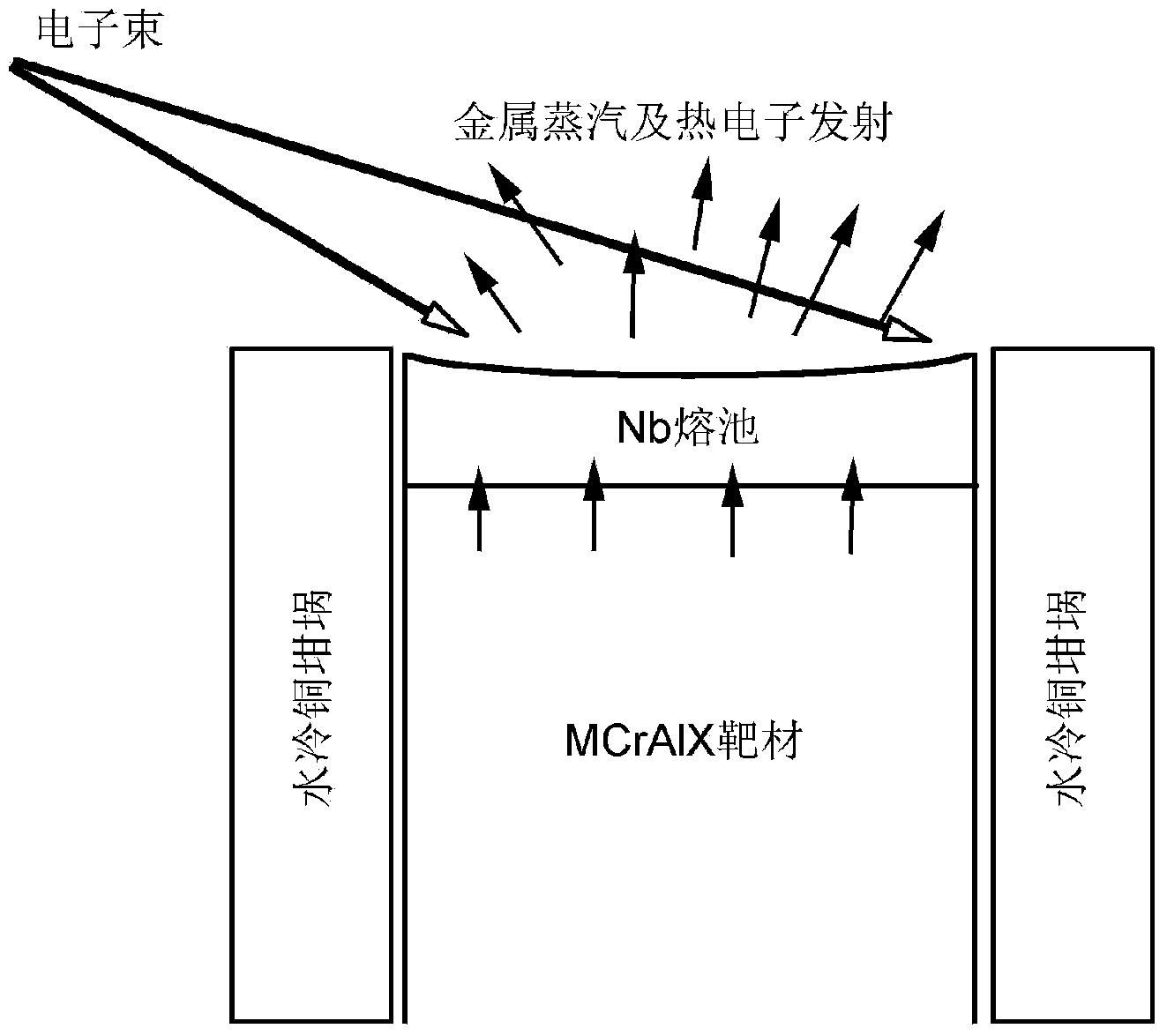

[0025] figure 1 It is a schematic diagram of the principle of using Nb molten pool to improve the thermionic emission ability of MCrAlX evaporation. When the target is melted and evaporated, the upper Nb molten pool emits a large number of thermal electrons, and the lower MCrAlX melts and passes through the Nb molten pool to generate a large amount of metal vapor. Taking the MCrAlX target with a diameter of 70mm as an example, 150-180g of Nb needs to be placed on it.

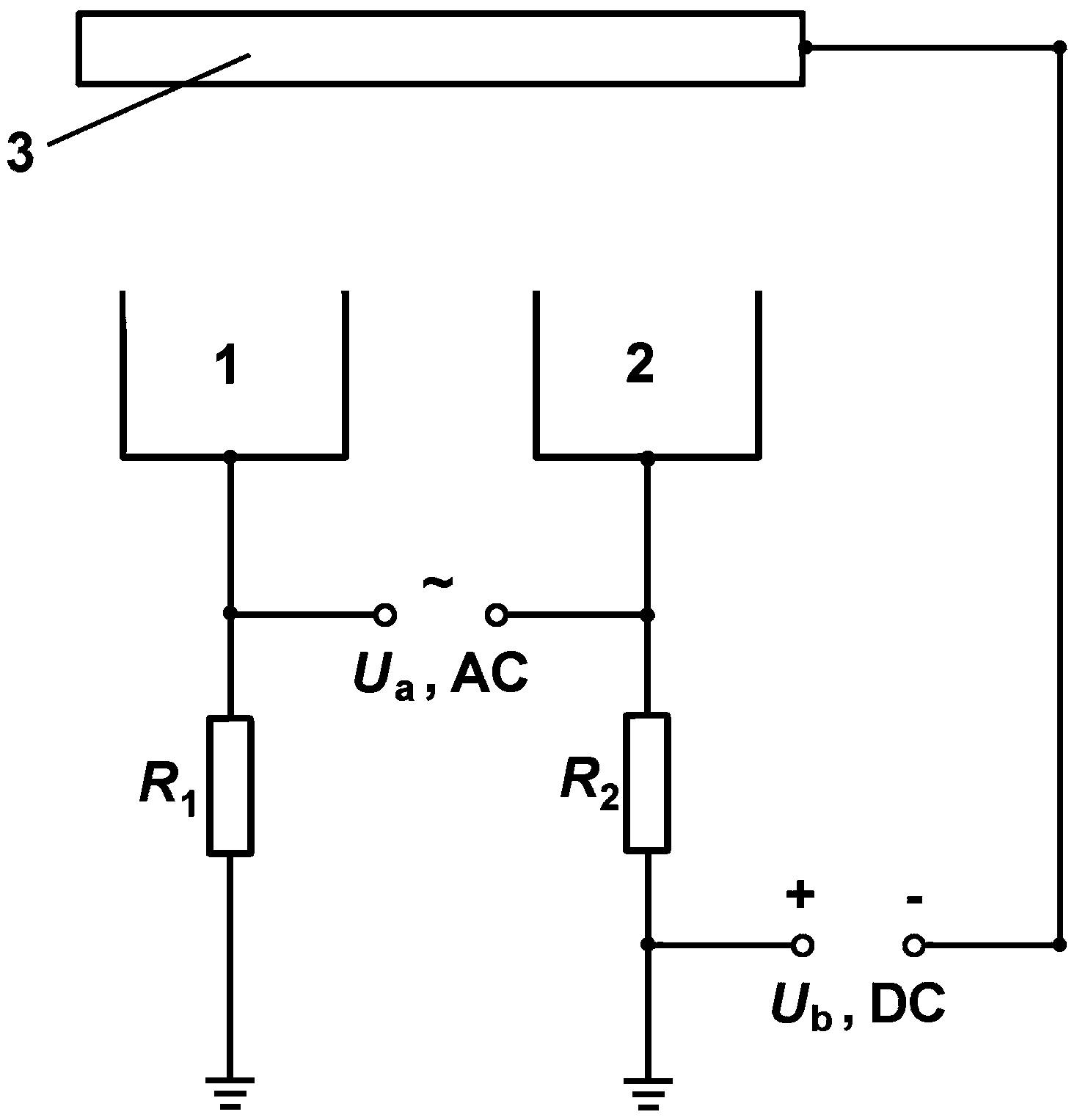

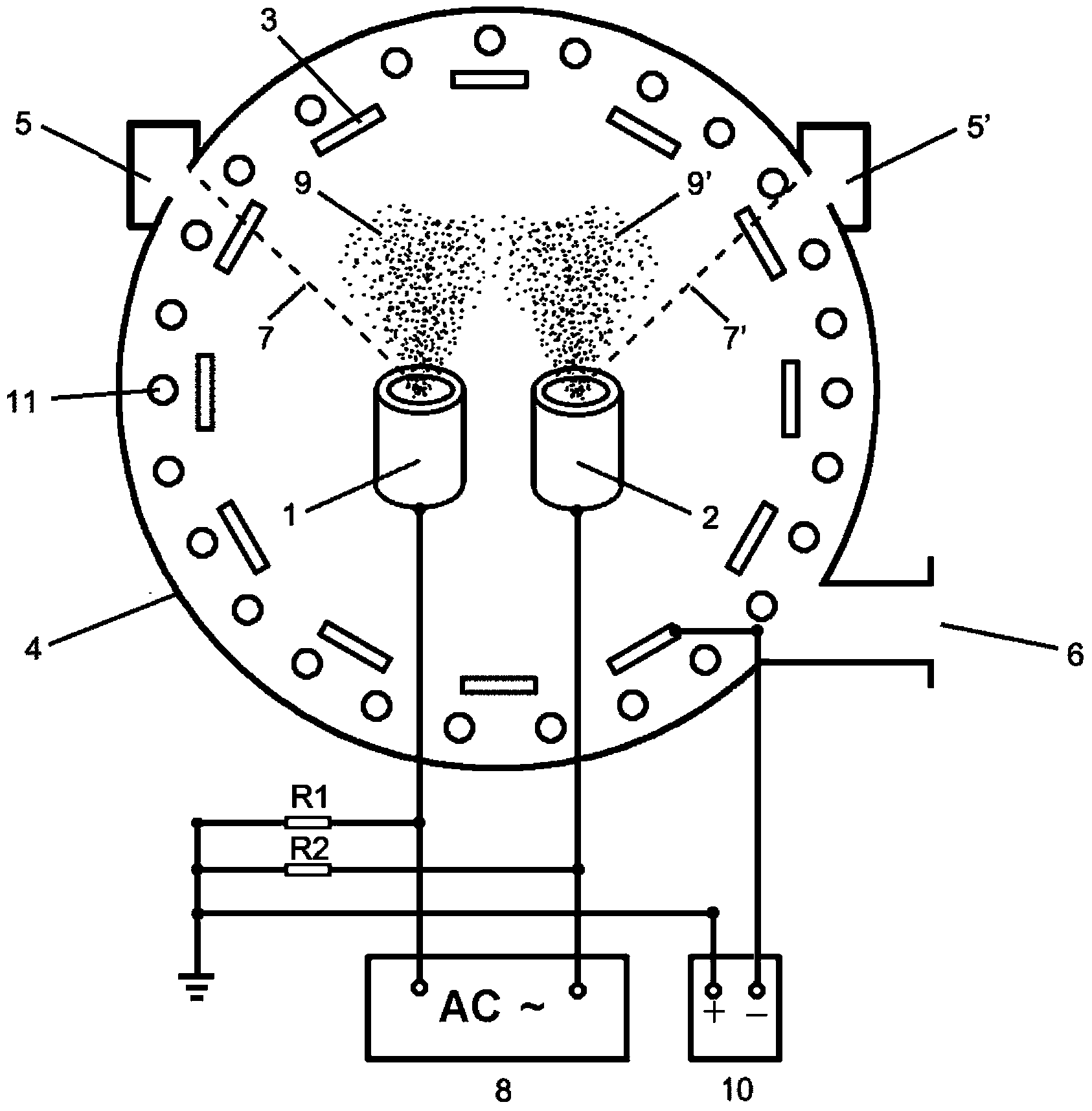

[0026] The MCrAlX coating deposition process described in the present invention needs to be realized by at least two MCrAlX evaporation crucibles with Nb molten pools, and the two evaporation crucibles are respectively connected to the two poles of the AC arc source. Under the action of the AC arc source, the metal vapor generated by the two evaporator crucibles alternately acts as the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com