Fog-resistant aqueous pressure-sensitive adhesive and polyethylene protection film containing same

A pressure-sensitive adhesive, fog water technology, applied in the direction of adhesives, ester copolymer adhesives, film/flake adhesives, etc. and other problems, to achieve the effect of improving anti-fogging performance, low production cost and increasing cross-linking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

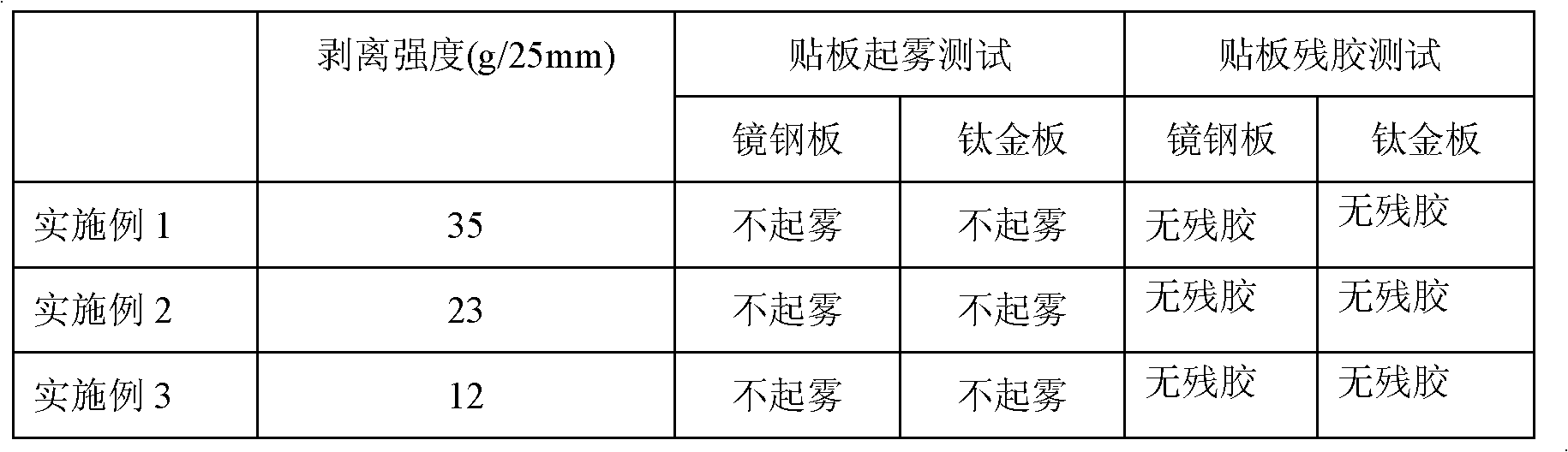

Examples

Embodiment 1

[0027] 1. Preparation of seed emulsion: 170 parts by weight of deionized water, 1.0 parts by weight of sodium alkylamide ethylene sulfonate (DNS-86), 0.80 parts by weight of sodium bicarbonate were added to a thermometer and a reflux condenser. In the four-necked flask, stir evenly, drop 20 parts by weight of methyl methacrylate and 7 parts by weight of butyl acrylate, then stir at a speed of 600 rpm, start to heat up to 80 ° C, and pass nitrogen in the system , deoxygenation, then 0.2 parts by weight of potassium persulfate was added to the system to initiate the polymerization of the system, and the reaction was performed for 50 minutes to obtain a seed emulsion;

[0028] 2. Preparation of pre-emulsion: 50 parts by weight of deionized water and 1.6 parts by weight of allyloxy nonylphenol polyoxyethylene ether ammonia sulfate (KL-100) were added to the there-necked flask, and 500 rpm was used. Stir the stirring speed evenly, then slowly mix 2 parts by weight of methyl methacr...

Embodiment 2

[0036] 1. Preparation of seed emulsion: 170 parts by weight of deionized water, 0.6 parts by weight of allyloxynonylphenol polyoxyethylene ether ammonium sulfate (SE-10), 0.60 parts by weight of sodium bicarbonate In the four-necked flask of the thermometer and the reflux condenser, stir evenly, drop 12 parts by weight of methyl methacrylate, 5 parts by weight of butyl acrylate, and 5 parts by weight of methyl acrylate, and then stir at a speed of 800 rev / min. , start to heat up to 65 ℃, pass nitrogen in the system to remove oxygen, then add 0.2 parts by weight of ammonium persulfate to the system, initiate the system to start polymerization, and react for 30 minutes to obtain a seed emulsion;

[0037] 2. Preparation of pre-emulsion: 50 parts by weight of deionized water and 0.9 parts by weight of allyloxy fatty alcohol polyoxyethylene ether ammonium sulfate (SR-10) were added to the three-necked flask, and the stirring at 1200 rpm was adopted. The speed is evenly stirred, and...

Embodiment 3

[0045] 1. Preparation of seed emulsion: 170 parts by weight of deionized water, 0.4 parts by weight of sodium vinyl sulfonate (SVS), 0.4 parts by weight of sodium allyl ether hydroxypropyl sulfonate (COPS-1), 1.20 The disodium hydrogen phosphate of weight portion was added in the four-necked flask with thermometer and reflux condenser, stirred, and 18 weight portions of methyl methacrylate and 20 weight portions of isooctyl acrylate were dropped, and then 400 rpm were used. Stir evenly at a speed of / min, start to heat up to 90 ° C, pass nitrogen in the system to remove oxygen, then add 0.18 parts by weight of ammonium persulfate into the system, initiate the system to start polymerization, and react for 20 minutes to obtain a seed emulsion;

[0046] 2. Preparation of pre-emulsion: 50 parts by weight of deionized water and 1.0 part by weight of sodium allyl ether hydroxypropyl sulfonate (COPS-1) were added to the three-necked flask, and stirred at a stirring speed of 800 rpm. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com