Preparation method of high-performance thin clad titanium/steel compound plates

A clad plate, thin clad technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of high maintenance costs, unfavorable industrial production, and time-consuming, and improve bonding performance and production efficiency. , the effect of low cost and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Step 1. Select a Q235A steel plate with a thickness of 64.0mm and a TA1 titanium plate with a thickness of 6.0mm, level the steel plate and titanium plate until the unevenness is 5.0mm / m, and cut the leveled steel plate to a length and width of 200mm ×400mm, cut the leveled titanium plate to a length and width of 150mm×350mm; then use the louver to remove the oxide layer, slag inclusions, cavities and other defects on the surface to be compounded of the cut steel plate and the titanium plate to be compounded, Expose the base metal; clean the steel plate and titanium plate with chemical pure ethanol to completely remove the residual oil and various adsorbates on the surface;

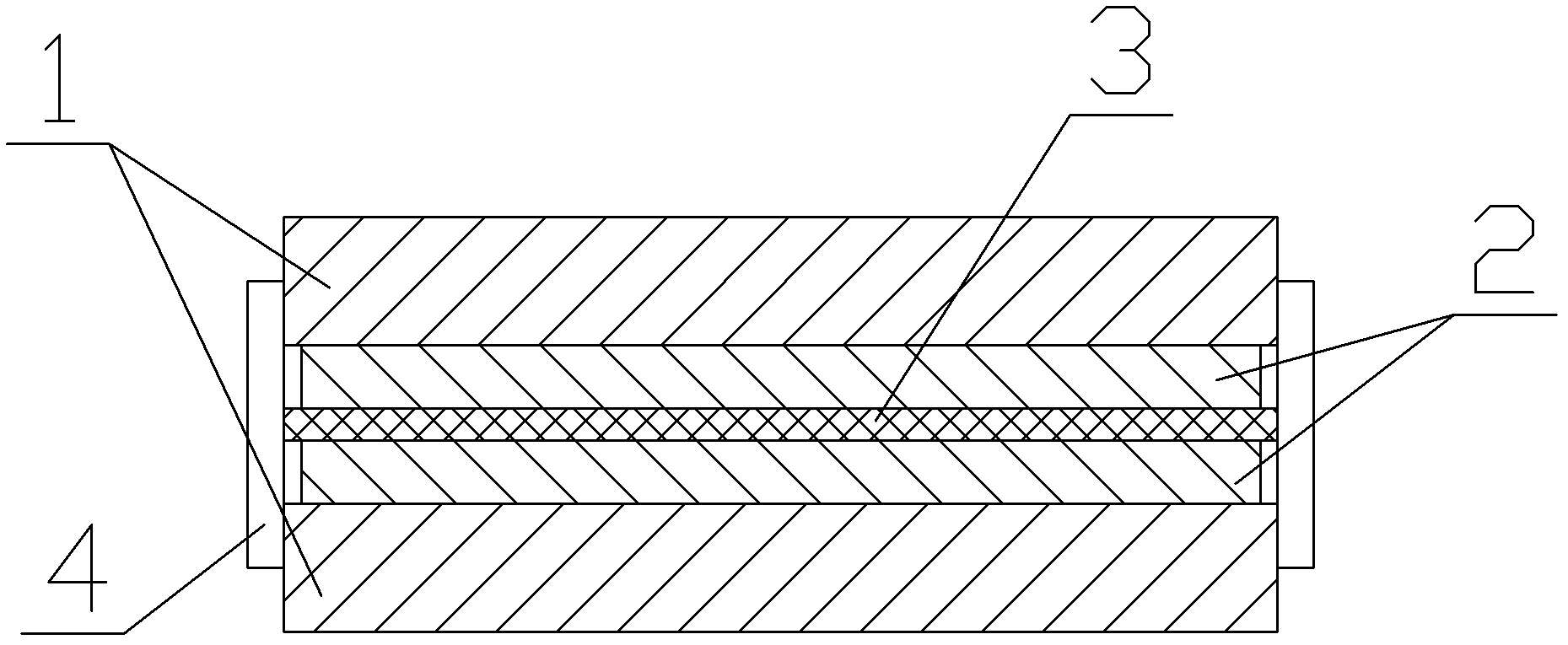

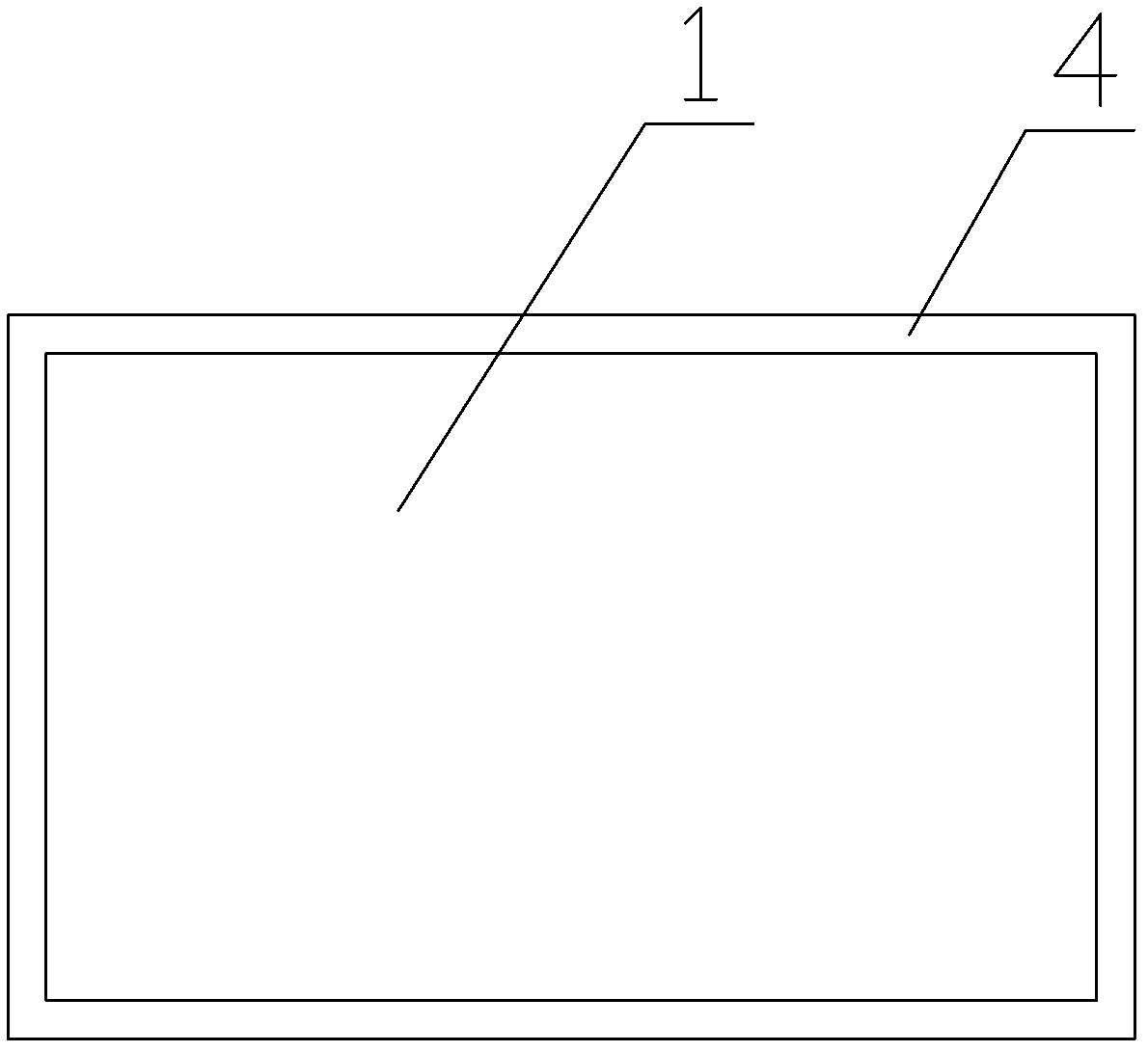

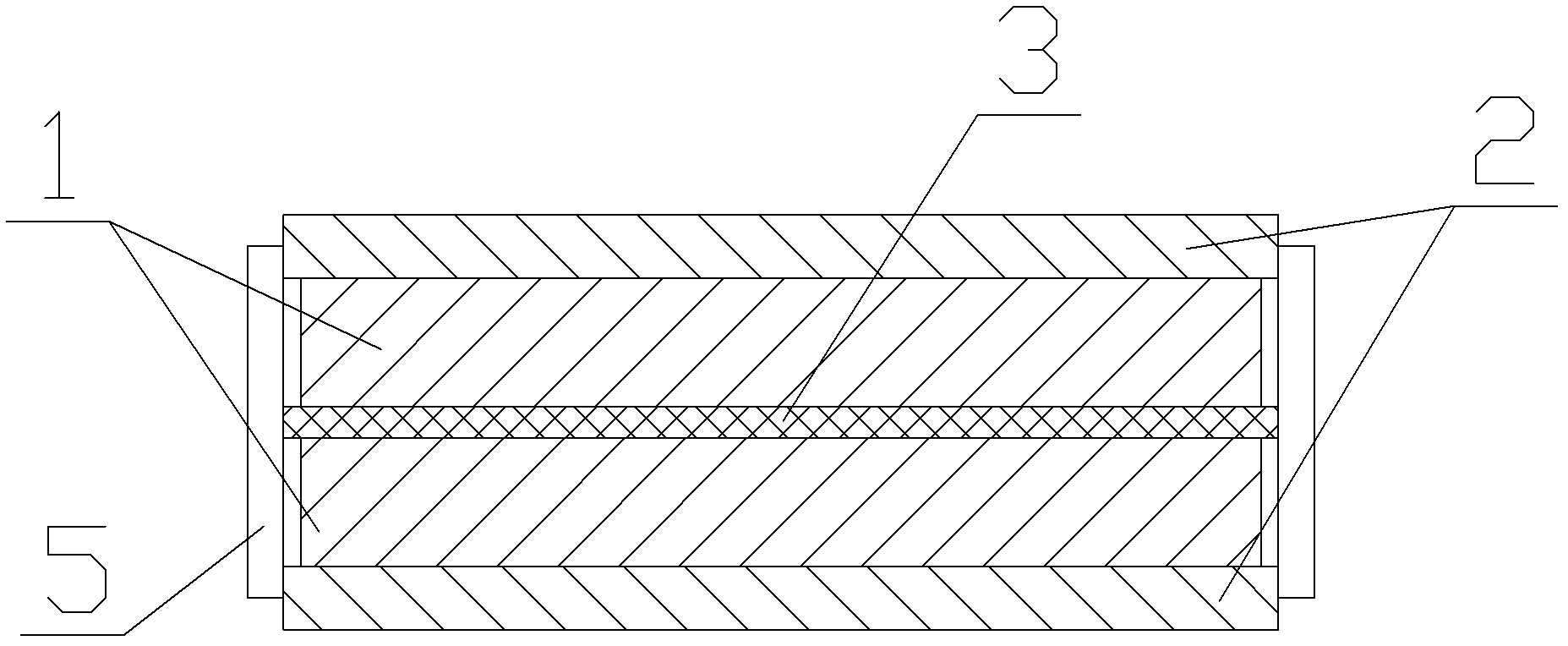

[0036] Step 2, assembling the cleaned steel plate and titanium plate into a slab in step 1; the way of assembling is as follows: figure 1 and figure 2 As shown, the surface to be compounded of the steel plate 1 and the surface to be compounded of the titanium plate 2 are stacked to form a slab, a...

Embodiment 2

[0042] Step 1. Select a Q345A steel plate with a thickness of 3.0mm and a TA2 titanium plate with a thickness of 3.0mm, level the steel plate and titanium plate until the unevenness is 4.0mm / m, and cut the leveled steel plate to a length and width of 200mm ×400mm, cut the leveled titanium plate to a length and width of 200mm×400mm; then use a wire brush to remove the oxide layer, slag inclusions, cavities and other defects on the surface to be compounded of the cut steel plate and the titanium plate to be compounded, Expose the base metal; clean the steel plate and titanium plate with chemical pure acetone to completely remove the residual oil stains and various adsorbates on the surface;

[0043] Step 2, assembling the cleaned steel plate and titanium plate into a slab in step 1; the way of assembling is as follows: figure 1 and figure 2As shown, the surface to be compounded of the steel plate 1 and the surface to be compounded of the titanium plate 2 are stacked to form a ...

Embodiment 3

[0049] Step 1. Select a Q345B steel plate with a thickness of 10.0mm and a TC2 titanium plate with a thickness of 10.0mm. Level the steel plate and titanium plate until the unevenness is 2.0mm / m, and cut the leveled steel plate to a length and width of 200mm. ×400mm, cut the leveled titanium plate to a length and width of 190mm×390mm; then use sandpaper to polish and remove the oxide layer, slag inclusions, voids and other defects on the surface to be compounded of the cut steel plate and the titanium plate to be compounded, Expose the base metal; clean the steel plate and titanium plate from which defects have been removed with a mixture of chemically pure ethanol and chemically pure acetone (volume ratio 1:1, or any ratio is acceptable), and thoroughly remove residual oil stains and various adsorbate;

[0050] Step 2, assembling the cleaned steel plate and titanium plate into a slab in step 1; the way of assembling is as follows: figure 1 and figure 2 As shown, the surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile shear strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com