Material assembling method and rolling method for titanium-steel clad plate

A composite plate and titanium steel technology, applied in the direction of metal rolling, etc., can solve the problems of high cost, complicated operation, and high requirements for welding equipment, and achieve the effect of solving interface oxidation, high bonding strength, and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

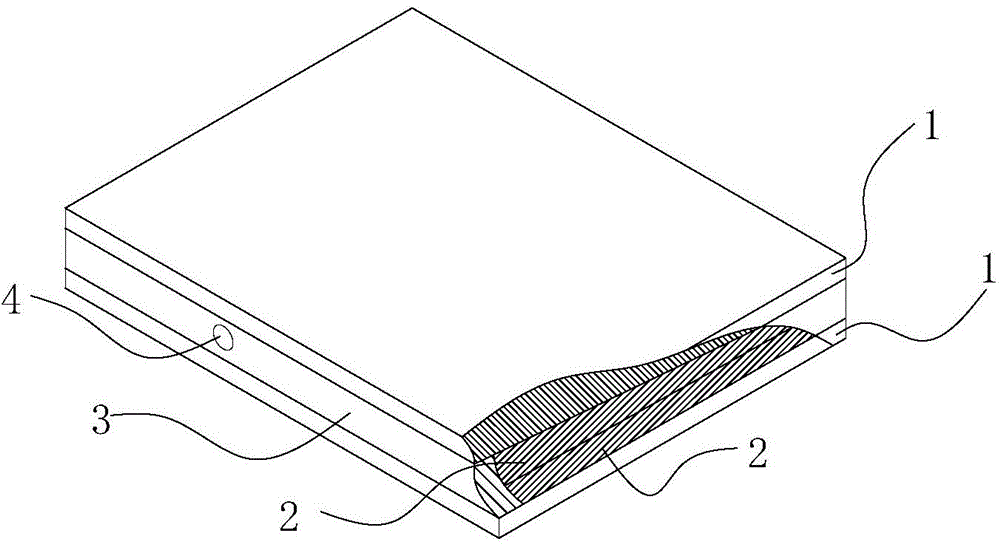

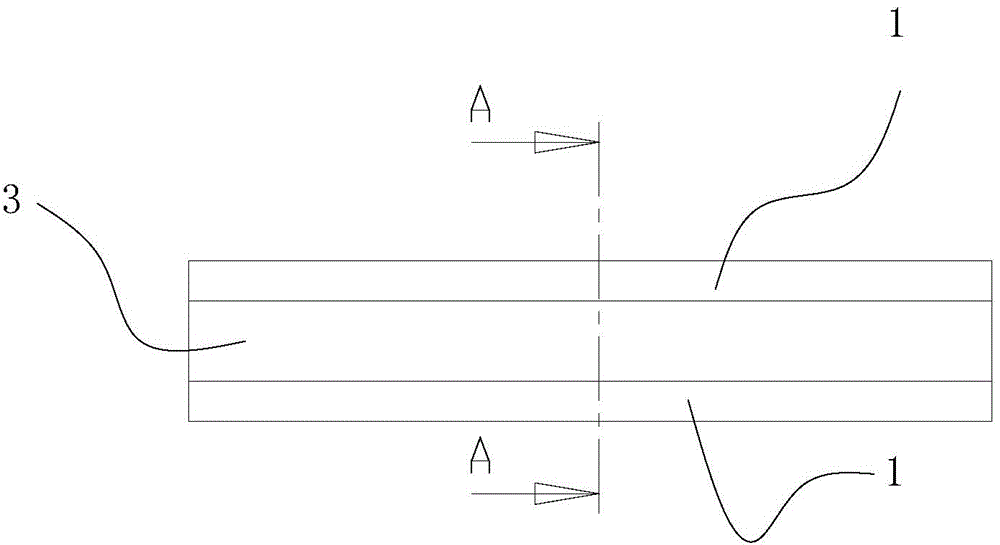

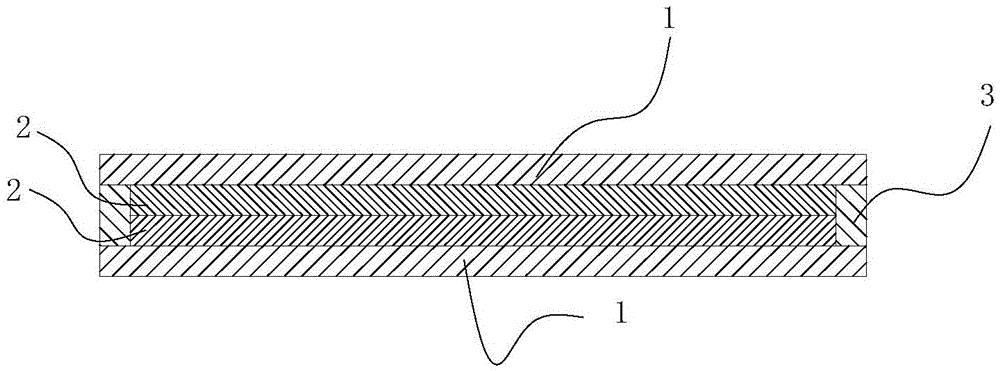

[0052] Carry out billet assembly as follows:

[0053] ①Process two steel plates and two titanium plates with dimensions of 200×160×18mm and 160×120×20mm respectively, two side plates of 120×20×40mm and 200×20×40mm respectively, and grind and polish the surface , to remove surface dirt and oxide layer;

[0054] ② Make a hole on one of the side plates, and weld a seamless carbon steel pipe with a wall thickness > 2mm at the hole;

[0055] ③ Then carry out symmetrical billet assembly in the order of steel plate / titanium plate / titanium plate / steel plate, coat the release agent on the adjacent surfaces of the two titanium plates, and set the side plate around the titanium plate and between the two steel plates , the gap between the steel plate and the side plate and the gap between the side plate and the side plate are welded by argon arc welding, so that all materials become a combination;

[0056] ④ After the welding is completed, connect the seamless carbon steel pipe to the vac...

Embodiment 2

[0059] Roll the titanium-steel clad plate as follows:

[0060] ①Put the combined billet prepared in Example 1 into a heating furnace and heat to 950°C, and keep it warm for 360min;

[0061] ② Take out the combined billet that has completed the heating process, and carry out rolling. The first pass is deformed by 10%, after 12 passes of rolling, the cumulative deformation is 88%, the rolling speed is 0.2m / s, and the final rolling temperature is 660°C;

[0062] ③ After the rolling is completed, the edge of the rolled plate is cut off, and the two titanium plates are naturally separated due to the action of the release agent, so that two titanium-steel composite plates can be obtained.

[0063] The obtained titanium-steel clad plate was tested for bonding strength, and the interface bonding strength was obtained to be 250MPa. Wherein, the bonding strength determination method is carried out according to the shear test method in GB / T 6396-2008.

Embodiment 3

[0065] Roll the titanium-steel clad plate as follows:

[0066] ①Put the combined billet prepared in Example 1 into a heating furnace and heat it to 780°C, and keep it warm for 360min;

[0067] ② Take out the combined billet that has completed the heating process, and carry out rolling. The first pass is deformed by 5%, after 12 passes of rolling, the cumulative deformation is 72%, the rolling speed is 0.1m / s, and the final rolling temperature is 600°C;

[0068] ③ After the rolling is completed, the edge of the rolled plate is cut off, and the two titanium plates are naturally separated due to the action of the release agent, so that two titanium-steel composite plates can be obtained.

[0069] The obtained titanium-steel clad plate was tested for bonding strength, and the interface bonding strength was obtained to be 190-200 MPa. Since the heating temperature and the amount of deformation are close to the lower limit, the bonding strength is low and fluctuates. Among them, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Interfacial bonding strength | aaaaa | aaaaa |

| Interfacial bonding strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com