Preparation process of composite roller

A preparation process and composite roll technology, which is applied in the field of roll production, can solve problems such as uneven structure, reduce roll production cost, inclusions, etc., and achieve the effect of improving interface bonding strength and improving alloy segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

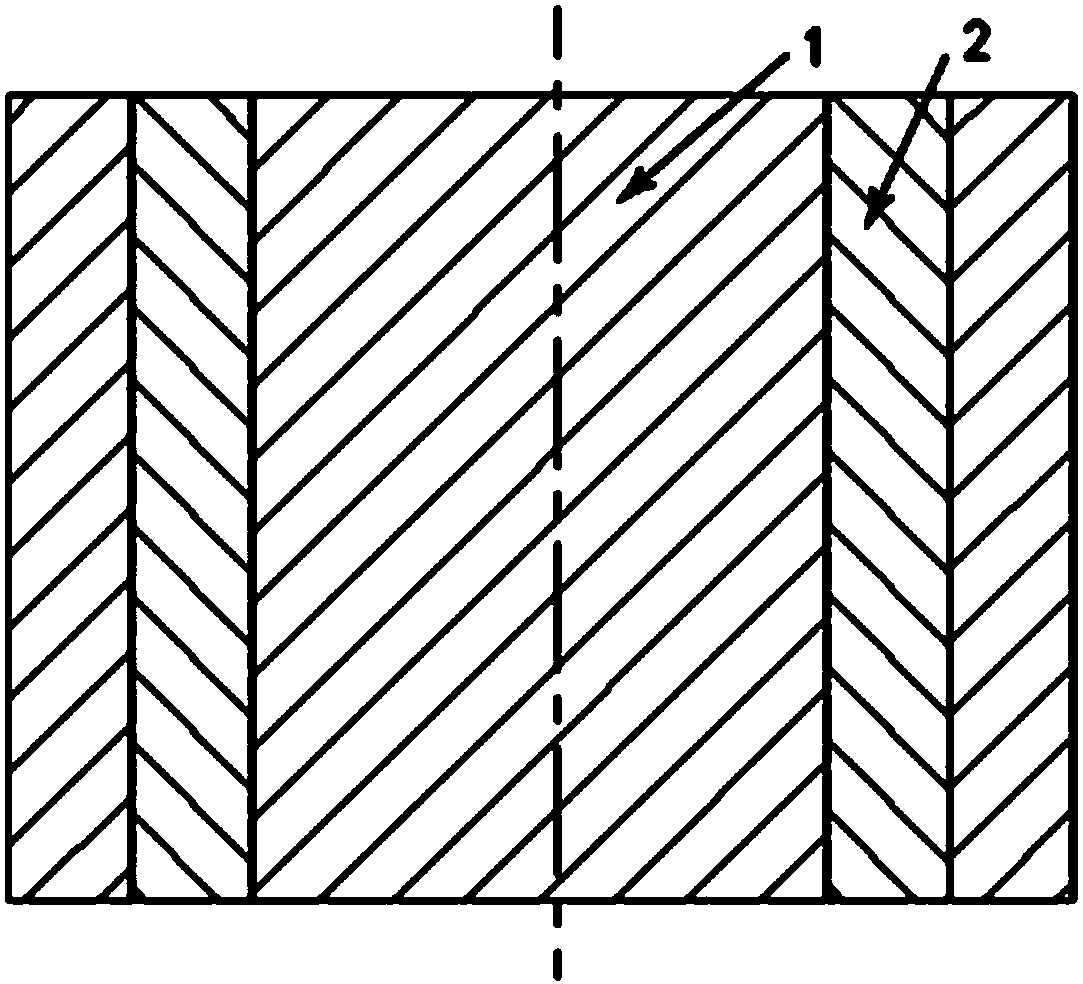

[0018] In this embodiment, a composite roll with a composite three-layer ring is to be manufactured, wherein the material of the first layer of the ring is 5Cr 5 MoV, the material of the second roller ring is 9Cr 2 , the third layer material is 8Cr 3 MoV, roller core material is 42CrMo steel. Its longitudinal and transverse cross-sectional structures are as figure 1 shown. The specific preparation process is as follows: first, the roller core and the three-layer roller ring are welded and sealed from the inside to the outside by the vacuum electron beam welding method, and the vacuum degree is 9.4×10 -3 Pa; heat the sealed roll ring and roll core to 1180±10°C, and keep it warm for 6h; start forging, and then carry out the pier thickening and elongation process in turn to realize the interface metallurgical bonding of the roll core and roll ring. The total forging ratio of pier thickening is 1.8, using the upper and lower V anvils to elongate the pier-thickened roll blank a...

Embodiment 2

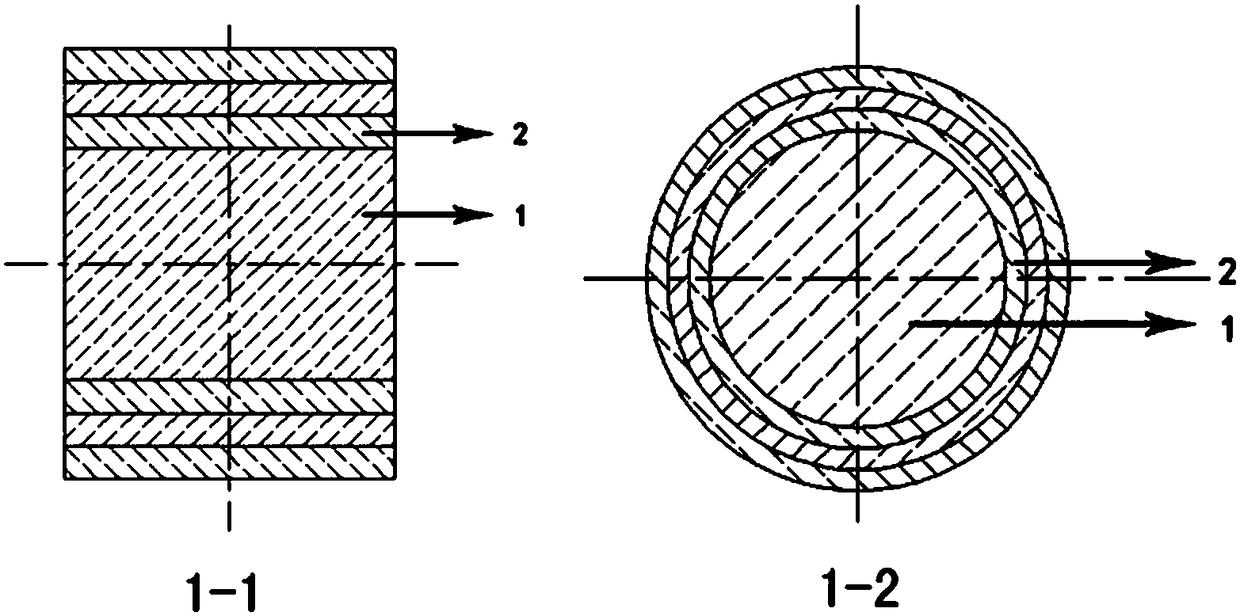

[0021] In this embodiment, a compound roll with a composite layer of roll ring will be manufactured, wherein the material of the roll ring is 5Cr 5 MoV, roller core material is 42CrMo. Its longitudinal and transverse cross-sectional structures are as figure 2 shown. The specific preparation process is as follows: use the manual arc welding method to first weld and seal the roller core and the roller ring, and then vacuumize, the vacuum degree is ≤8.6×10 -3 Pa; heat the sealed roll ring and roll core to 1170±10°C, and keep it warm for 4 hours; start forging, and carry out the pier thickening and elongation process in turn to realize the interface metallurgical bonding of the roll core and roll ring, wherein the total forging ratio of pier thickening is ≥ 1.5, using the upper and lower circular arc anvils to elongate the pier-thickened roll blank and roll core, the total forging ratio of elongation is 2.4; and then the composite roll is obtained through subsequent heat treatm...

Embodiment 3

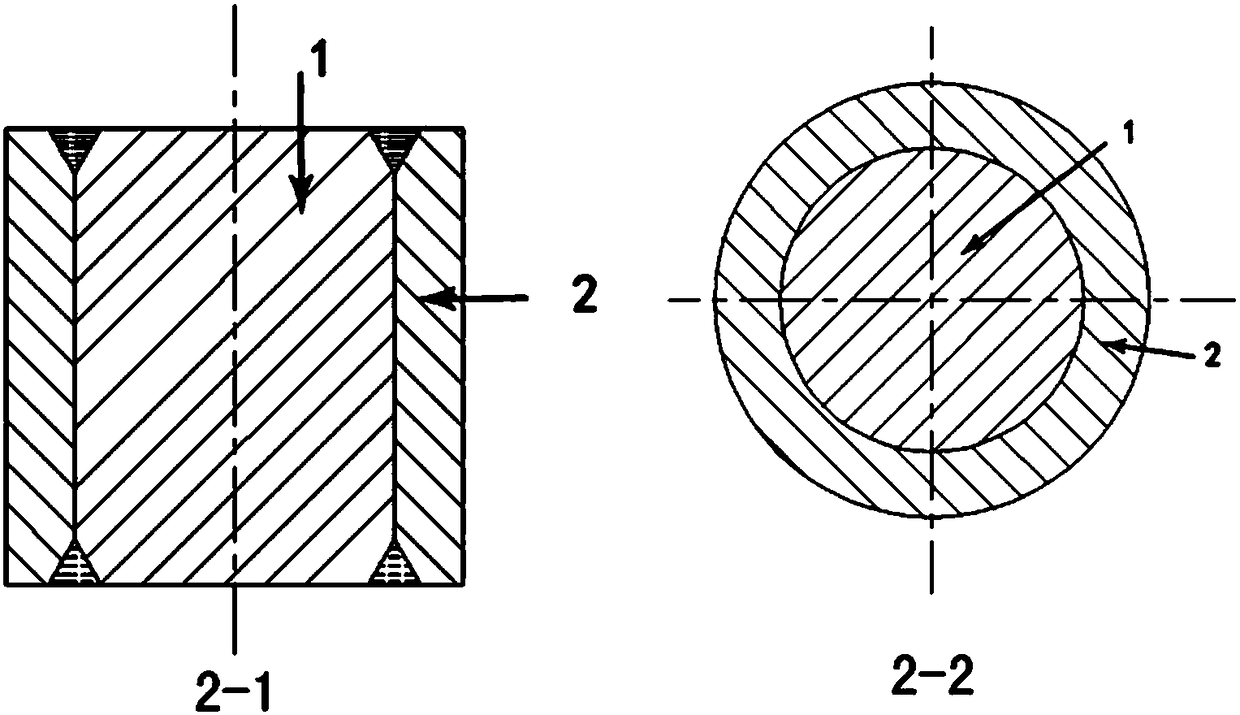

[0024] In this embodiment, a composite roll with a composite two-layer roll ring is to be manufactured, wherein the first layer of roll ring material is 5Cr 5 MoV, the material of the second roller ring is 9Cr 2 , Roller core material is 45 steel. Its longitudinal section structure is as image 3 shown. The specific preparation process is as follows: first, the roller core and the second layer of roller ring are welded and sealed from the inside to the outside by the vacuum friction stir welding method, and the vacuum degree is ≤7.8×10 -3 Pa; heat the sealed roll ring and roll core to 1170±10°C, and keep it warm for 5h; start forging, and then carry out the pier thickening and elongation process in turn to realize the interface metallurgical bonding of the roll core and roll ring. The total forging ratio of pier thickening is 1.6, using the upper and lower V anvils to elongate the pier-thickened roll blank and roll core, the total forging ratio of elongation is 2.6; and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com