Production method for ultralong thin titanium/steel compound plate

A composite plate, thin technology, applied in metal rolling, manufacturing tools, welding equipment and other directions, can solve the problems of high rolling mill capacity, low bonding strength, few applications, etc., to achieve low production cost, high production efficiency, The effect of excellent strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

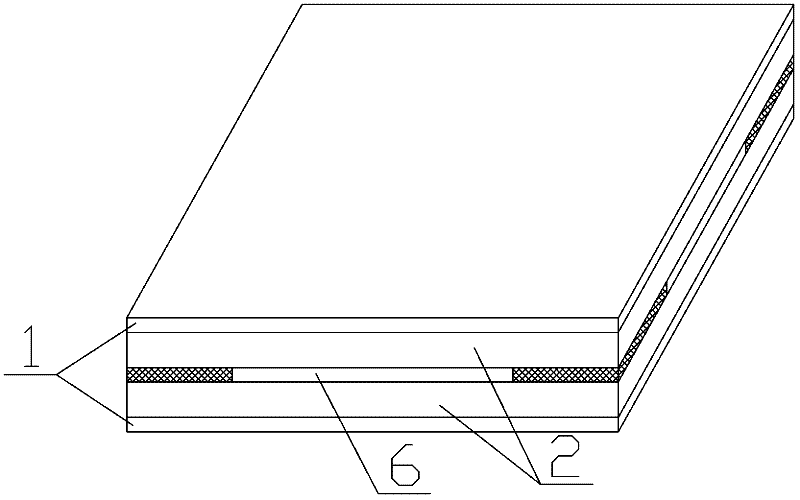

[0026] Step 1. Perform shape correction treatment on the clad titanium plate 1 so that the unevenness of the clad titanium plate 1 is not greater than 1mm / m, and then heat treat the clad titanium plate 1 after the shape correction treatment at a temperature of 580°C for 2 hours, and then furnace cooling; the thickness of the clad titanium plate 1 is 3mm;

[0027] Step 2, cleaning and polishing the base steel plate 2 and the clad titanium plate 1 after heat treatment in step 1, so that the surface roughness of the base steel plate 2 and the clad titanium plate 1 is not greater than 3 μm; the base steel plate 2 The thickness is 10mm;

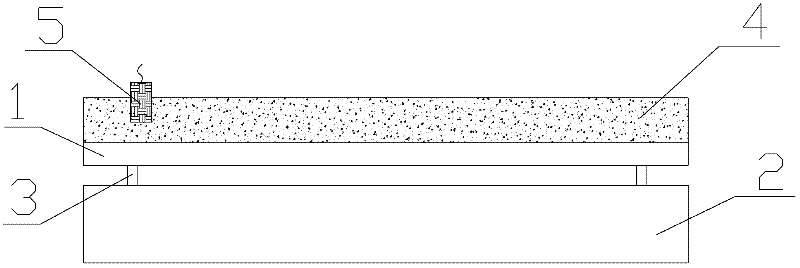

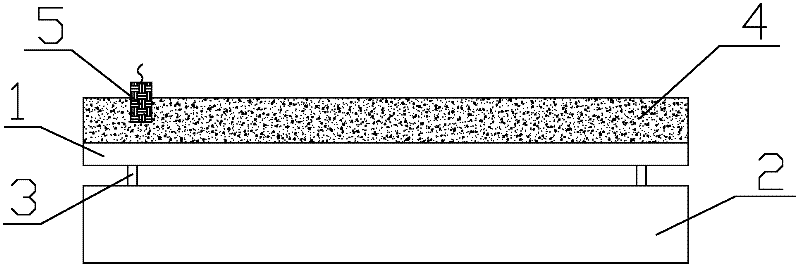

[0028] Step 3: Evenly arrange two supports 3 on the polished base steel plate 2 in step 2, then place the polished multilayer titanium plate 1 on the supports 3 in step 2, and finally place the explosive 4 on the on the multilayer titanium plate 1, and set the detonating charge 5 on the explosive, and carry out explosive welding to prepare the co...

Embodiment 2

[0035] Step 1. Perform shape correction treatment on the clad titanium plate 1 so that the unevenness of the clad titanium plate 1 is not greater than 1mm / m, and then heat treat the clad titanium plate 1 after the shape correction treatment at a temperature of 680° C. for 1 hour, and then furnace cooling; the thickness of the clad titanium plate 1 is 5mm;

[0036] Step 2, cleaning and polishing the base steel plate 2 and the clad titanium plate 1 after heat treatment in step 1, so that the surface roughness of the base steel plate 2 and the clad titanium plate 1 is not greater than 3 μm; the base steel plate 2 The thickness is 20mm;

[0037] Step 3. Three supports 3 are evenly arranged on the polished base steel plate 2 in step 2, and then the polished multi-layer titanium plate 1 in step 2 is placed on the supports 3, and finally the explosive 4 is placed on the support 3. on the multilayer titanium plate 1, and set the detonating charge 5 on the explosive, and carry out exp...

Embodiment 3

[0044] Step 1. Perform shape correction treatment on the clad titanium plate 1 so that the unevenness of the clad titanium plate 1 is not greater than 1mm / m, and then heat treat the clad titanium plate 1 after the shape correction treatment at a temperature of 640° C. for 3 hours, and then Furnace cooling; the thickness of the clad titanium plate 1 is 8mm;

[0045] Step 2, cleaning and polishing the base steel plate 2 and the clad titanium plate 1 after heat treatment in step 1, so that the surface roughness of the base steel plate 2 and the clad titanium plate 1 is not greater than 3 μm; the base steel plate 2 The thickness is 40mm;

[0046] Step 3. Four supports 3 are uniformly arranged on the polished base steel plate 2 in step 2, and then the polished multilayer titanium plate 1 in step 2 is placed on the supports 3, and finally the explosive 4 is placed on the support 3. on the multilayer titanium plate 1, and set the detonating charge 5 on the explosive, and carry out e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com