Ultrahigh-temperature gradient heat insulation material and preparation method thereof

A thermal insulation material, ultra-high temperature technology, applied in chemical instruments and methods, paper/cardboard layered products, layered products, etc., can solve the problems of short service time, decreased thermal insulation performance, low temperature resistance of thermal protection materials, etc. , to achieve the effect of short production cycle and wide selection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

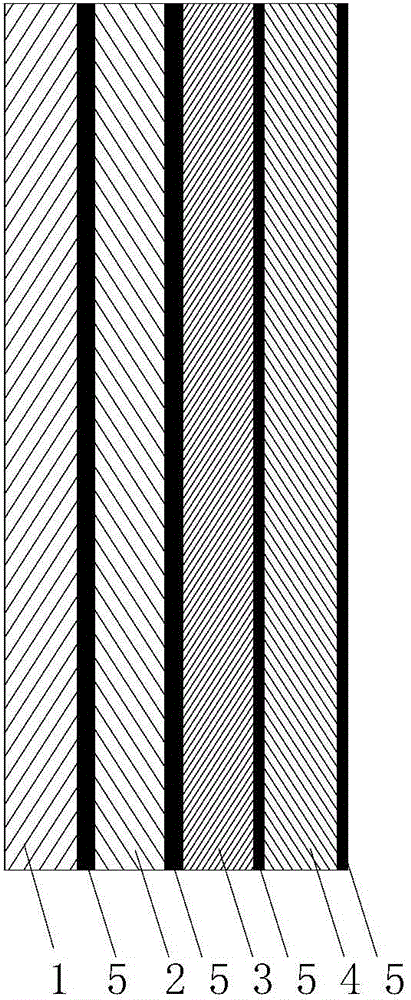

[0044] According to the application environment, use the heat transfer theory to determine the specific material and thickness of each heat insulation material layer; prepare each heat insulation material layer with a corresponding thickness according to the determined material; connect each heat insulation material layer with an adhesive to obtain a super high temperature Combined insulation.

[0045] The material and thickness of each layer of the ultra-high temperature composite heat insulation material determined through the above steps are as follows: the material used for the ultra-high temperature heat insulation material layer is carbon fiber / zirconia fiber ultra-high temperature heat insulation material with a thickness of 2mm; phase change heat absorption and heat insulation The material layer is made of magnesium fluoride phase-change material with a thickness of 2mm; the material used for the medium temperature insulation layer is alumina fiber insulation material w...

Embodiment 2

[0047] The difference between this embodiment and Embodiment 1 is that the materials and thicknesses used for each layer of the ultra-high temperature composite heat insulation material are as follows: the thickness of the ultra-high temperature heat insulation material layer is 2mm; the thickness of the phase change heat absorption heat insulation material layer is 10mm; The thickness of the heat insulation layer is 30mm; the material used for the low temperature heat insulation layer is aluminum silicate fiber heat insulation material with a thickness of 40mm; the material used for the radiation shielding layer is aluminum foil with a thickness of 0.01mm. Among them, the ultra-high temperature heat insulation material layer and the phase change heat absorption heat insulation material layer are bonded with an aluminum phosphate high-temperature adhesive, and the phase change heat absorption heat insulation layer and the medium temperature heat insulation layer, and the medium ...

Embodiment 3

[0049]The difference between this embodiment and Embodiment 1 is that the material and thickness of each layer of the ultra-high temperature composite heat insulation material are as follows: the material used for the ultra-high temperature heat insulation material layer is a zirconia fiber ultra-high temperature heat insulation material with a thickness of 2 mm; The heat insulation material layer is made of nickel fluoride phase change material with a thickness of 10mm; the material used for the medium temperature heat insulation layer is mullite fiber heat insulation material with a thickness of 2mm; the material used for the low temperature heat insulation layer is silica airgel heat insulation Material, the thickness is 2mm; the material used for the radiation shielding layer is gold foil, the thickness is 0.1mm. Among them, the ultra-high temperature heat insulation material layer and the phase change heat absorption heat insulation material layer are bonded with an alumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com