Surimi-based product with high jelly strength and preparation method thereof

A production method and technology for surimi products, applied in the field of food processing, can solve the problems of increased product cost, introduction of exogenous substances, etc., and achieve the effects of fine tissue structure and full elasticity in taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

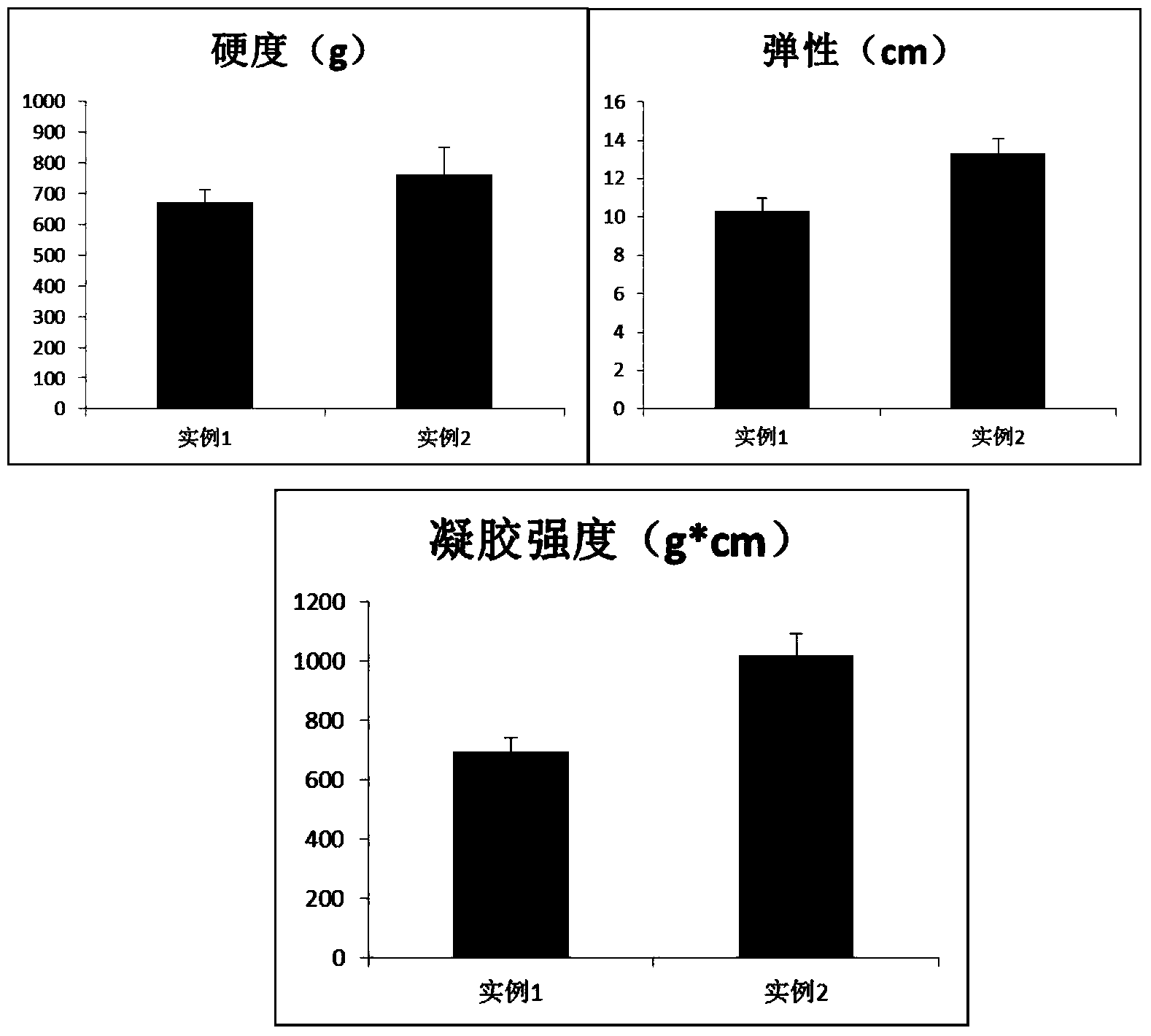

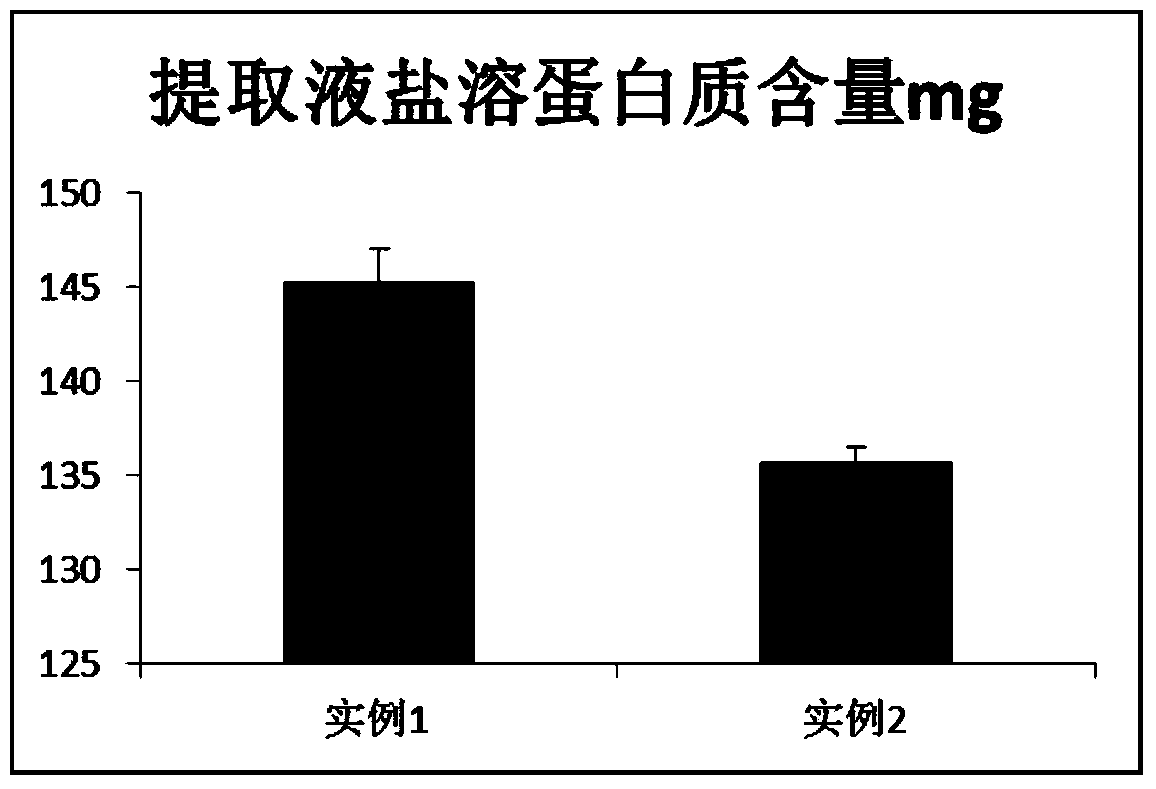

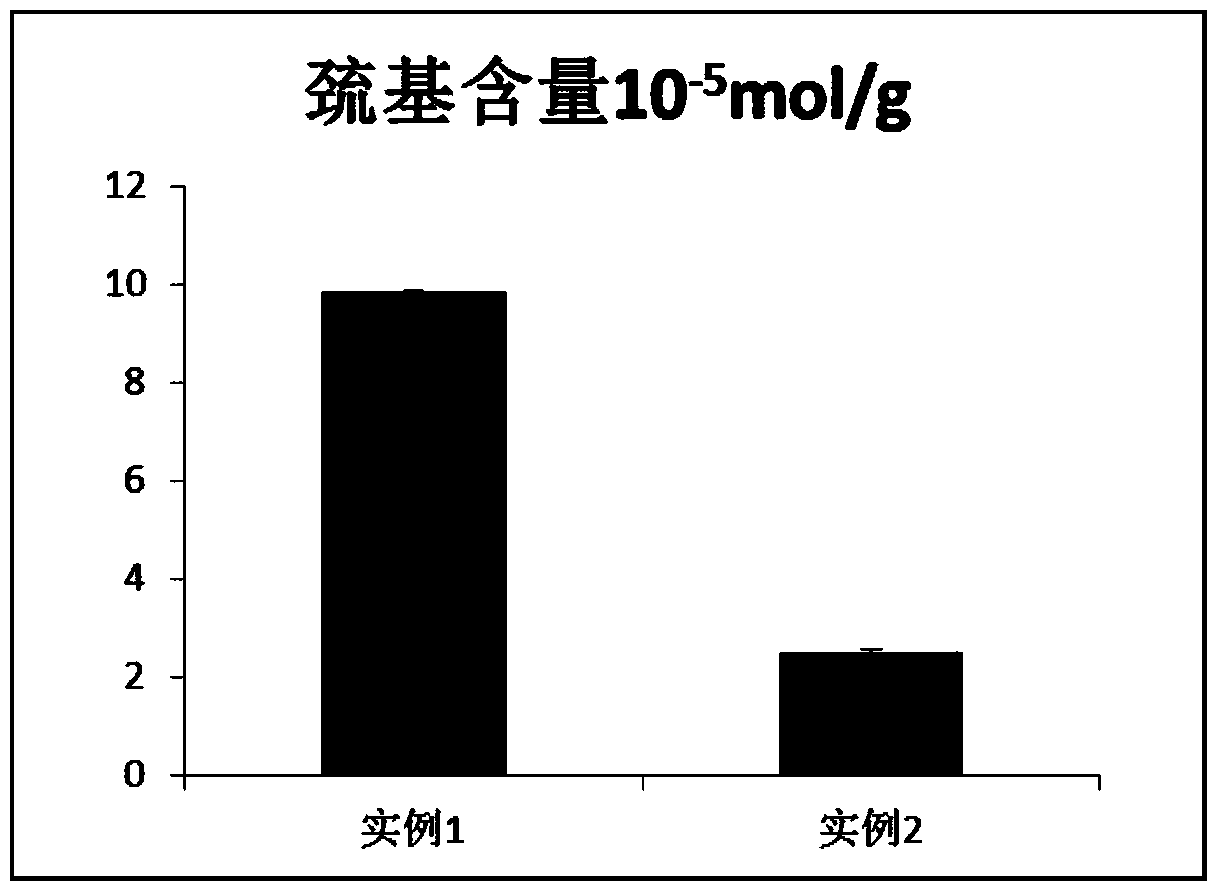

[0097] Embodiment 1: the production of high gel strength surimi products

[0098] The implementation steps of this embodiment are as follows:

[0099] A. Empty cut

[0100] Allow golden thread fish mince to be cut in a chopping machine sold by Shanghai Shenfa Machinery Co., Ltd. under the condition of a rotating speed of 2800r / min in a chopping machine sold by Shanghai Shenfa Machinery Co., Ltd. under the condition of 2800r / min; 5 times, chopping in the chopping machine for 28s each time, and then let the chopping machine stop stirring for 30s;

[0101] B. Salt cut

[0102] According to 2.0% of the surimi weight, add salt to the empty chopped surimi obtained in step A, mix evenly, and then cut the salt for a total of 3.5min under the condition of a rotating speed of 2800r / min in the chopping machine; 4 times, chopping in the chopping machine for 32s each time, then let the chopping machine stop stirring for 30s

[0103] C. mixed cut

[0104] According to 0.4‰ of the weigh...

Embodiment 2

[0108] Embodiment 2: the production of high gel strength surimi products

[0109] The implementation steps of this embodiment are as follows:

[0110] A. Empty cut

[0111] Let the golden thread fish surimi be chopped for a total of 2.0min under the condition of a rotating speed of 2000r / min in a chopping machine sold by Shanghai Shenfa Machinery Co., Ltd. with the trade name "Shenfa" brand; Carry out each time, cut in the chopping machine for 30s each time, and then let the chopping machine stop stirring for 30s;

[0112] B. Salt cut

[0113] According to 2.8% of the surimi weight, add salt to the empty chopped surimi obtained in step A, mix evenly, and then salt cut a total of 4.0min under the condition of rotating speed 2000r / min in the same chopping machine; Divide into 6 times, chop in the chopping machine for 28s each time, and then let the chopping machine stop stirring for 30s

[0114] C. mixed cut

[0115] According to 0.1‰ of the weight of surimi, add an aqueous...

Embodiment 3

[0119] Embodiment 3: the production of high gel strength surimi products

[0120] The implementation steps of this embodiment are as follows:

[0121] A. Empty cut

[0122] Allow golden thread fish surimi to be chopped for a total of 2.8 minutes under the condition of a rotating speed of 2400r / min in a chopping machine sold by Shanghai Shenfa Machinery Co., Ltd. with the trade name "Shenfa" brand; Carry out each time, chopping in the chopping machine for 32s each time, and then let the chopping machine stop stirring for 30s;

[0123] B. Salt cut

[0124] According to 4.0% of the surimi weight, add salt to the surimi obtained in step A, mix evenly, then in the same chopping machine, salt chop a total of 2.0min under the condition of rotating speed 2400r / min; Divide into 5 times, chop in the chopping machine for 30s each time, then let the chopping machine stop stirring for 30s

[0125] C. mixed cut

[0126] According to 0.9‰ of the weight of surimi, add an aqueous solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com