Bright and beautiful-color real-stone-feeling paint and preparation method thereof

A real stone paint, bright technology, applied in the field of architectural decoration coatings, can solve the problems of poor water resistance and weather resistance, poor batch stability, easy cracking of the paint film, etc., to achieve bright and lasting color, less fine powder content, and batch stability. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

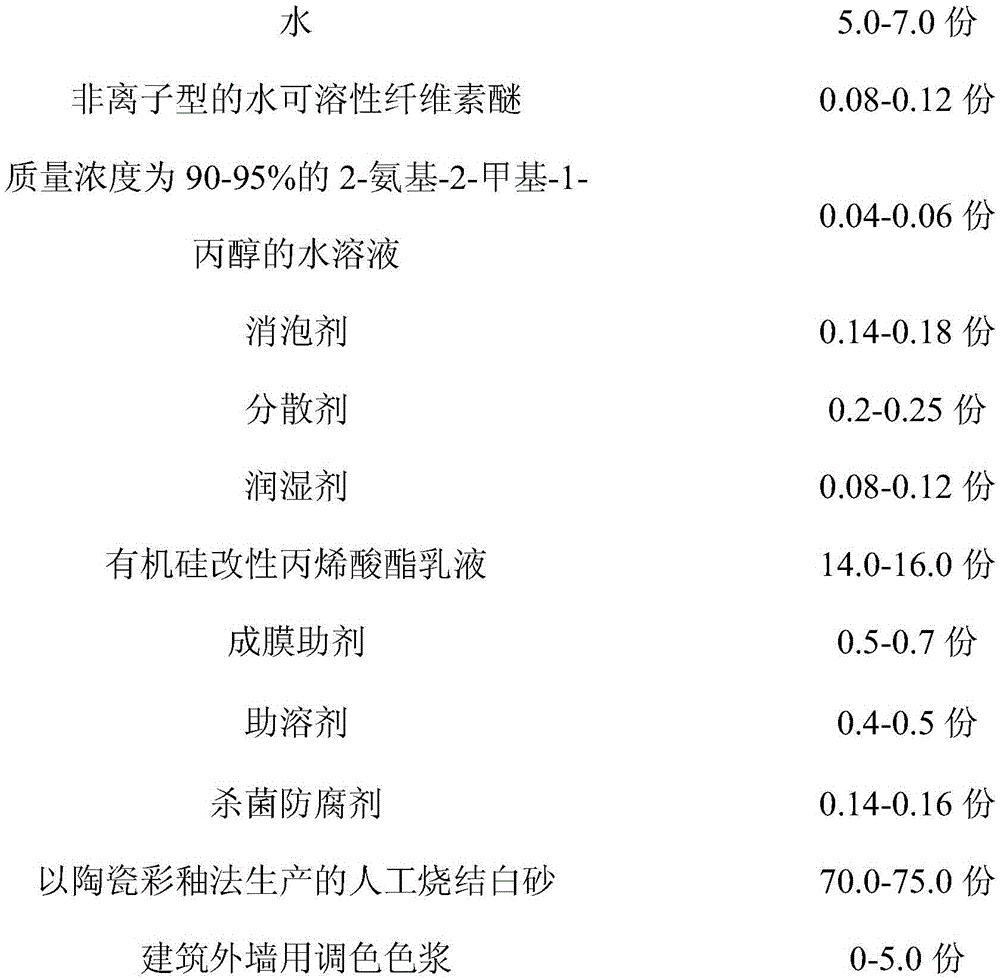

[0032] A kind of glossy real stone paint, it is formulated by the components of the following weight parts ratio,

[0033]

[0034]

[0035] This bright color real stone paint comprises the following steps carried out in sequence:

[0036] (1) Add non-ionic water-soluble cellulose ether and hydroxypropyl methylcellulose to the water under stirring at a rotating speed of 700r / min, stir for 4min, and continue to add 2-amino-2 with a mass concentration of 92% while stirring. -The aqueous solution of methyl-1-propanol, then increase the rotating speed to 900r / min and stir for 8min;

[0037] (2) under stirring at a rotating speed of 700r / min, in the mixture prepared in step (1), add successively its own total weight 8 / 15 oil-based defoamer, polyacrylic acid sodium salt dispersant, nonionic surfactant, Non-ionic microemulsion compounded by ultra-high molecular weight polysiloxane and surfactant, dimethylsiloxane emulsion, silicone modified pure acrylate copolymer, alcohol est...

Embodiment 2

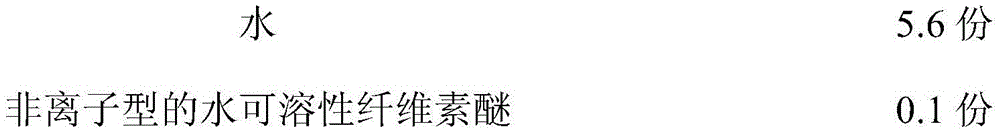

[0040] A kind of glossy real stone paint, which is formulated by the following components in parts by weight:

[0041]

[0042] This bright color real stone paint comprises the following steps carried out in sequence:

[0043] (1) Add non-ionic water-soluble cellulose ether and water retaining agent to the water under stirring at a speed of 500r / min, stir for 5min, and continue to add 2-amino-2-methyl-1 with a mass concentration of 90% while stirring. -Aqueous solution of propanol, then increase the rotating speed to 1000r / min and stir for 5min;

[0044] (2) Under stirring at a rotating speed of 500r / min, to the mixture prepared in step (1), sequentially add its own total weight of 7 / 15 silicone defoamer, polyacrylic acid ammonium salt dispersant, wetting agent, lotus leaf hydrophobic agent, powder type water repellent, silicone modified acrylate emulsion, film-forming aid, co-solvent, remaining silicone defoamer, bactericidal preservative, rheological additive, and then s...

Embodiment 3

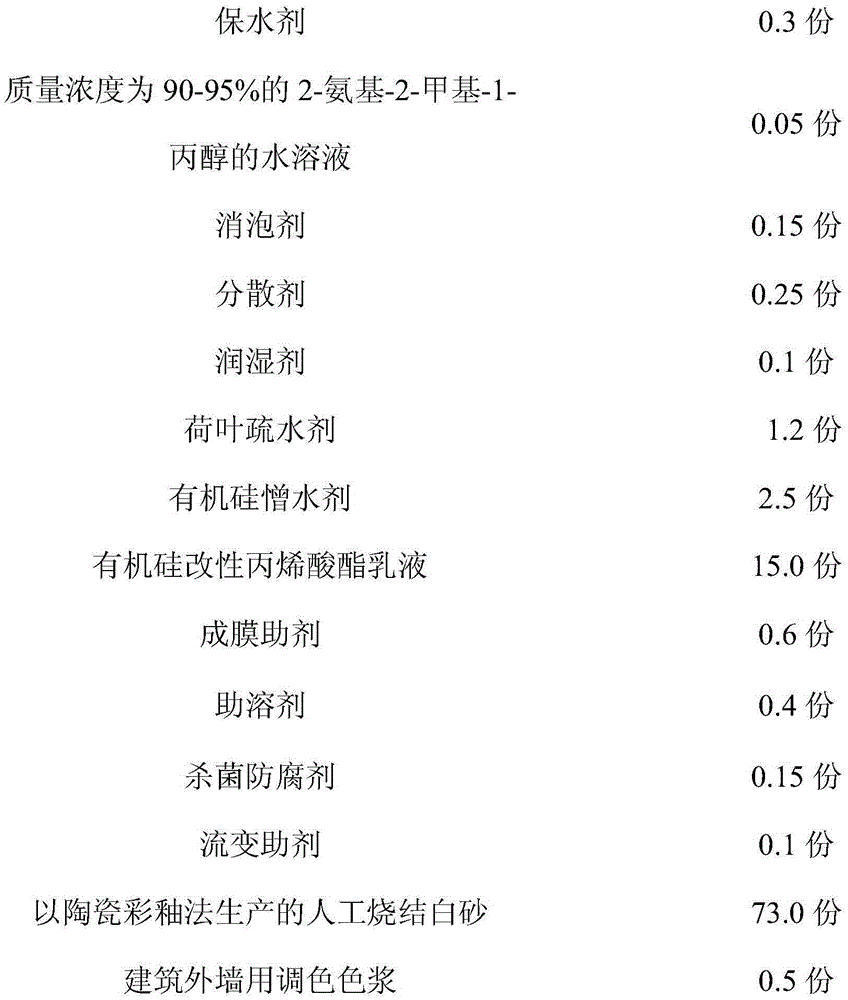

[0047] A kind of glossy real stone paint, which is formulated by the following components in parts by weight:

[0048]

[0049]

[0050] This bright color real stone paint comprises the following steps carried out in sequence:

[0051] (1) Add non-ionic water-soluble cellulose ether and water-retaining agent to the water under stirring at a speed of 750r / min, stir for 3 minutes, and continue to add 2-amino-2-methyl-1 with a mass concentration of 95% while stirring. -Aqueous solution of propanol, then increase the rotating speed to 1000r / min and stir for 5min;

[0052] (2) under stirring at a rotating speed of 750r / min, in the mixture prepared in step (1), add successively an emulsion type defoamer, dispersant, wetting agent, lotus leaf hydrophobic agent, Silicone water repellent, silicone modified acrylate emulsion, film-forming aids, co-solvents, remaining emulsion-type defoamers, bactericidal preservatives, rheological additives, and then stirred at 800r / min for 10 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com